Solid-liquid separation vacuum suction filtration device and suction filtration method using same

A technology of vacuum filtration and solid-liquid separation, applied in separation methods, fixed filter element filters, filtration and separation, etc., can solve the problems of slow filtration speed, low filtration efficiency, and high application cost, reduce filtrate loss, improve Suction filtration efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present application provides a vacuum filtration device for solid-liquid separation and a suction filtration method using the device, so that the volume of the obtained filtrate can form a good match with the volume of the collection system bottle.

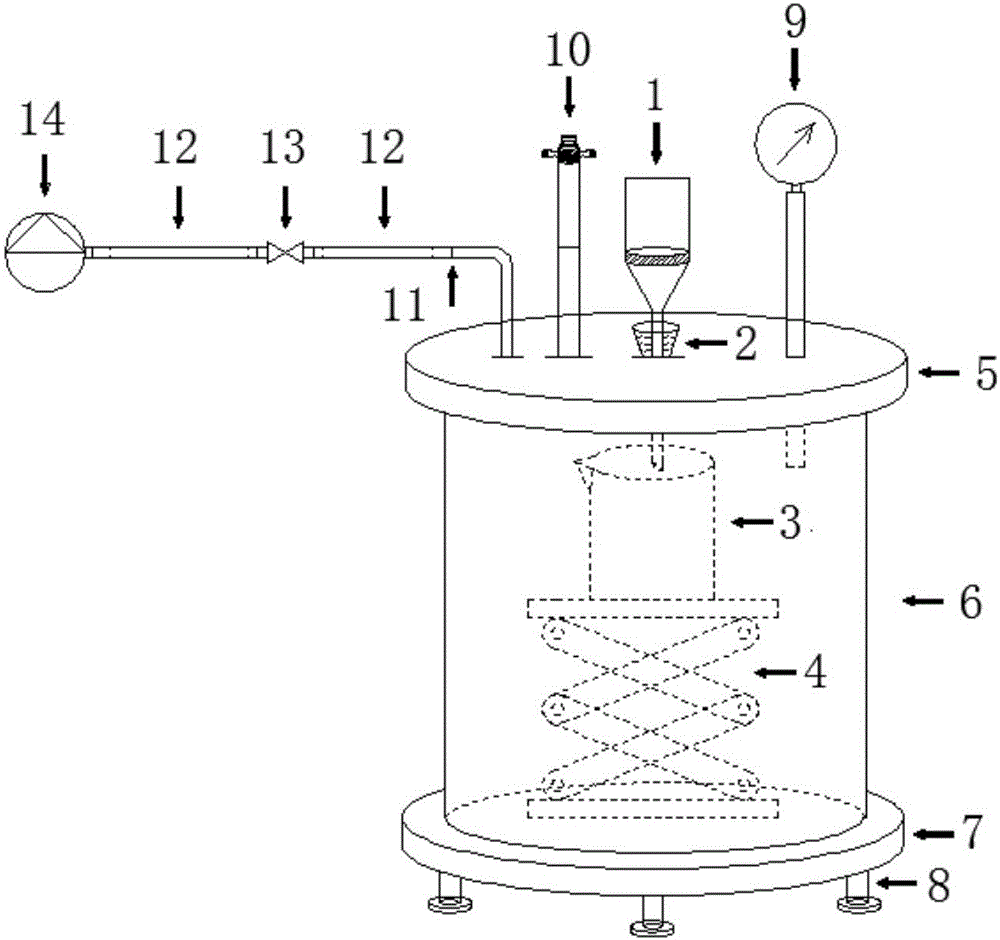

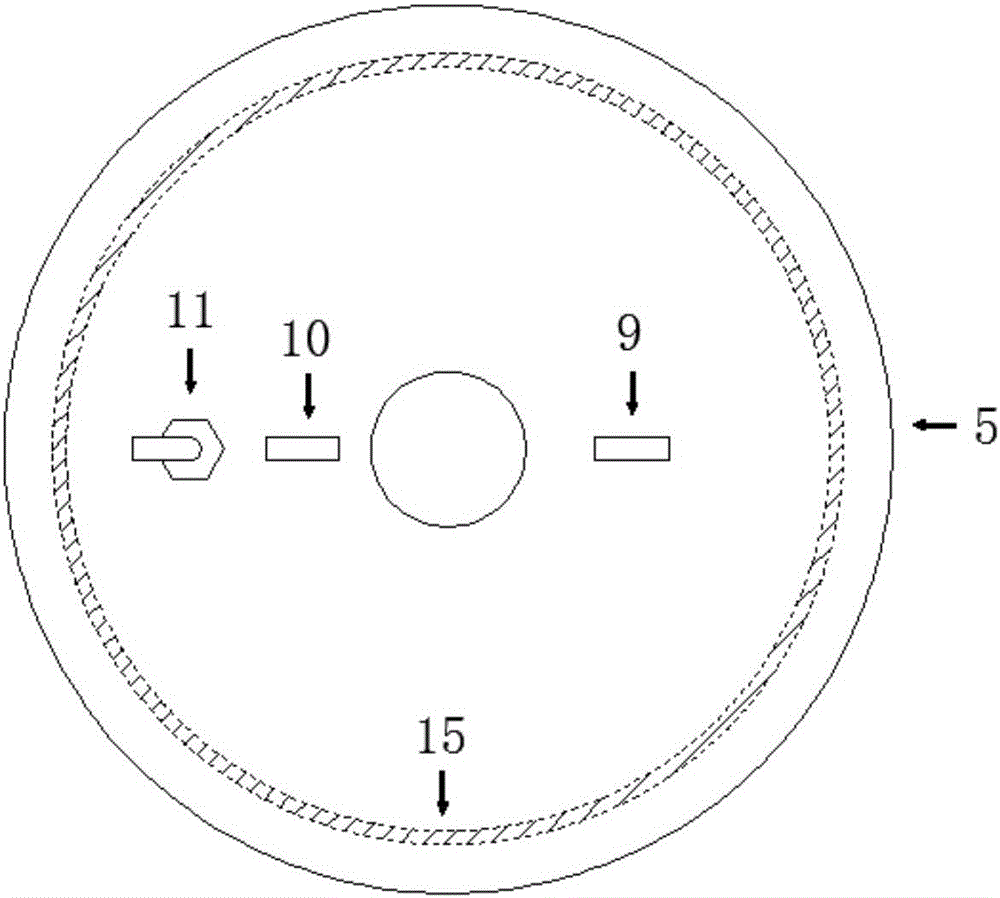

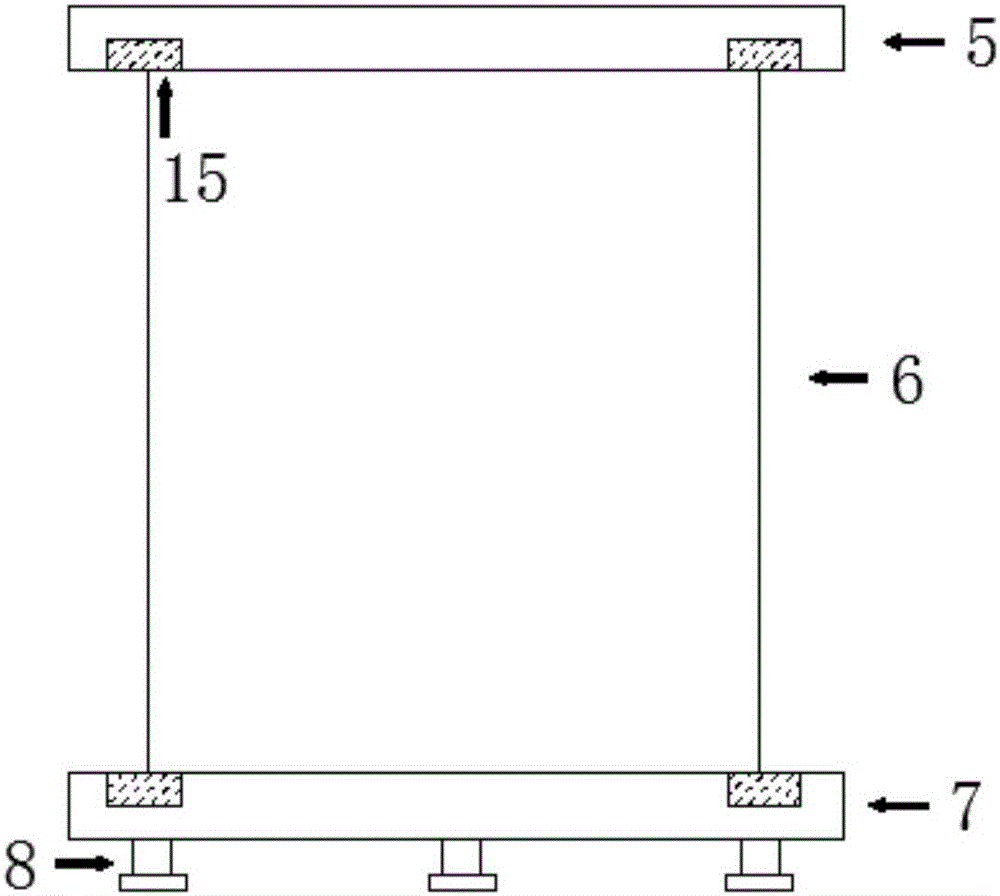

[0035] The vacuum filtration device for solid-liquid separation in the embodiment of the present application includes a filtration system, a collection system, a vacuum pump, and a closed chamber. The filtrate outlet of the filtration system is connected to the collection system, and the filtrate outlet and the collection system are located in the closed chamber. The sealed chamber is provided with a pumping port extending to the outside, and one end of the pumping port located outside is connected to a vacuum pump; the sealed chamber is surrounded by an upper sealing cover, a sealing cylinder and a lower sealing cover to form a closed space; the sealed chamber A lifting device is arranged inside the chamber, and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com