A dough crusher

A technology of crusher and pellet, which is used in the mechanical crushing of plastic bulk material pellets. The effect of reducing labor production costs and reducing safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail.

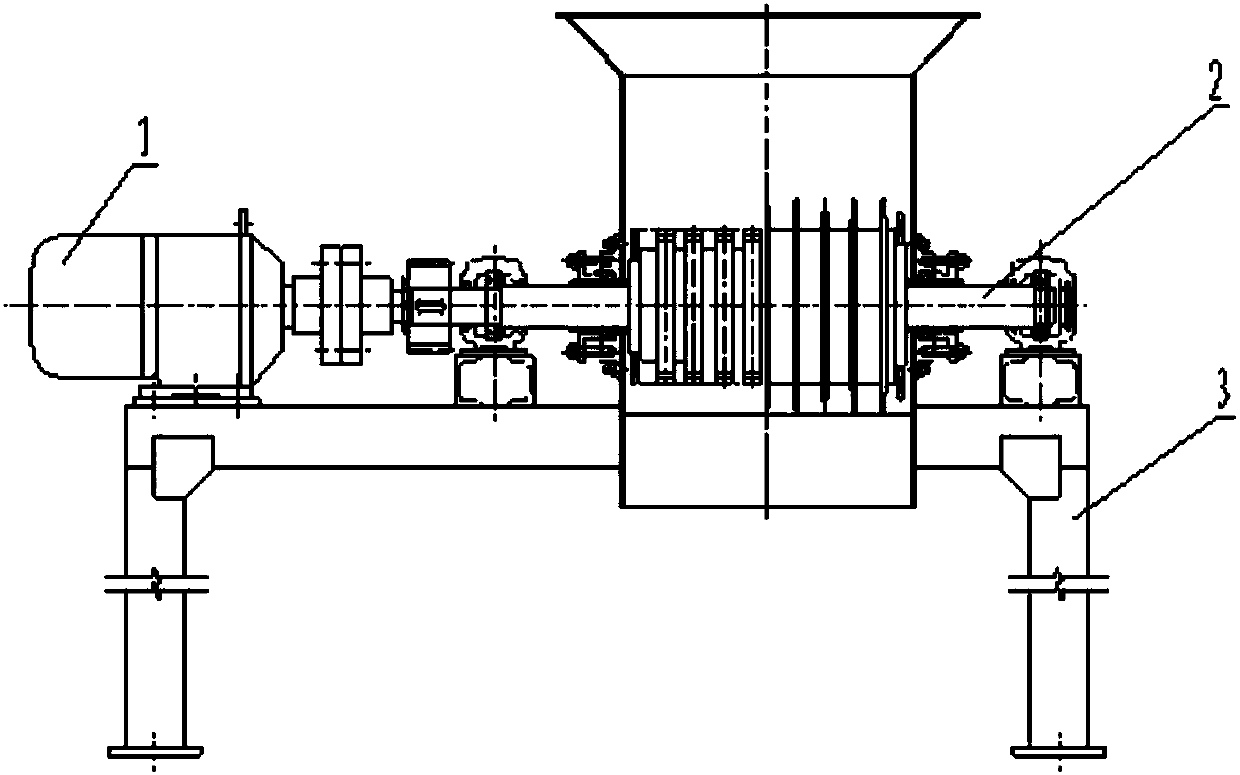

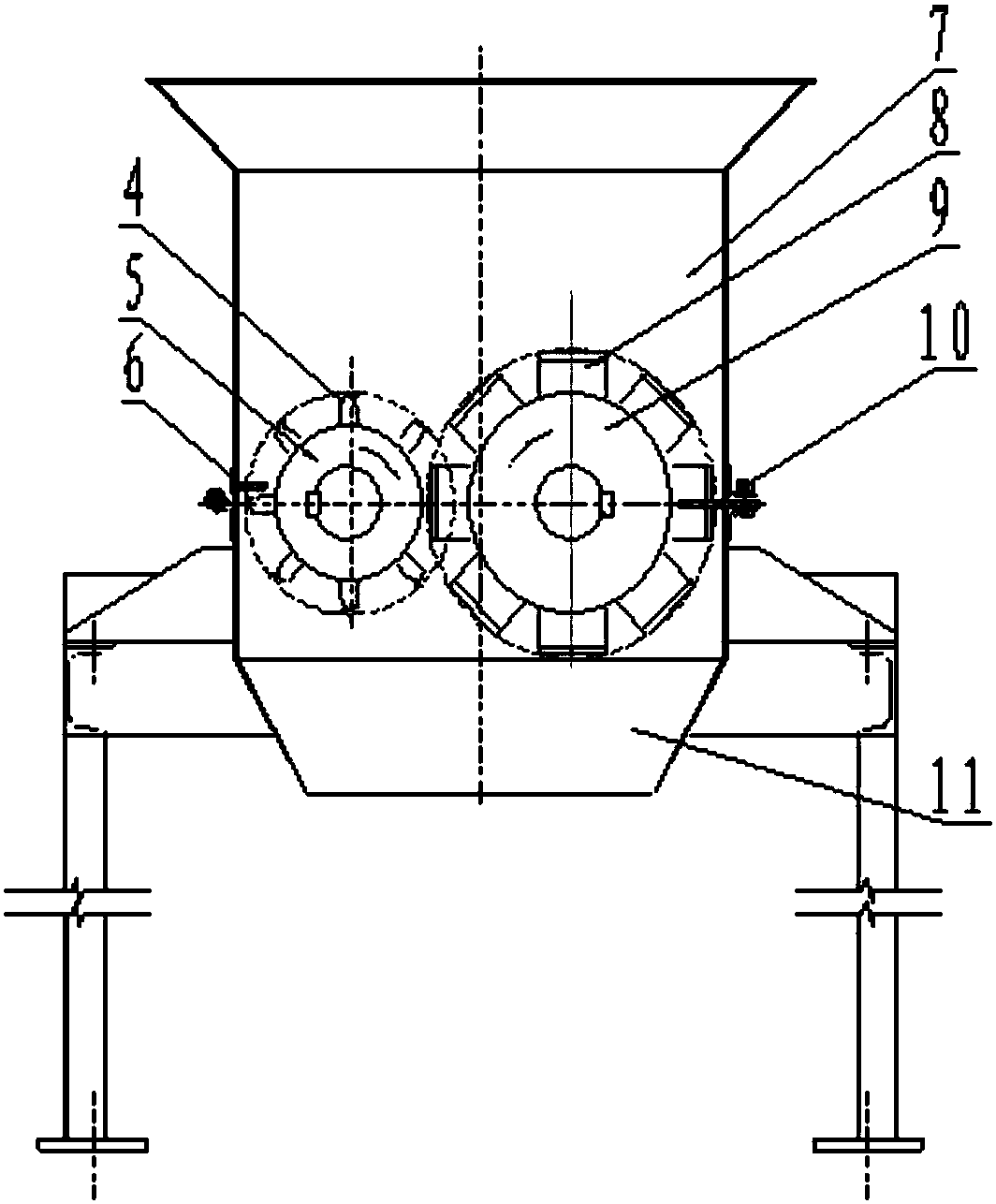

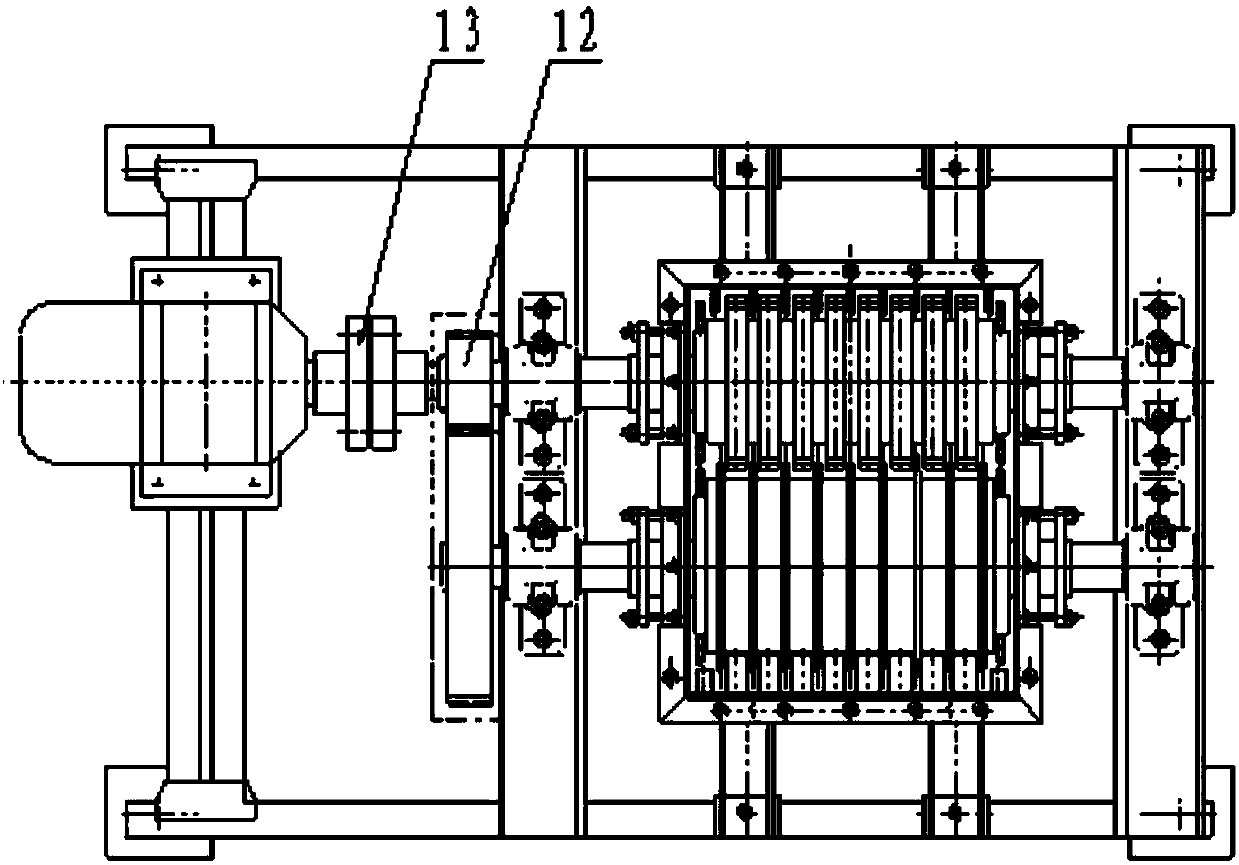

[0012] The present invention provides a dough crusher, comprising an explosion-proof motor 1, a rotating shaft 2, a bracket 3, a cutting roller 5, reverse feeding teeth 6, 10, a feeding bin 7, a bar roller 9, a feeding bin 11, and a transmission gear 12 , Coupling 13;

[0013] The explosion-proof motor 1 and the feed bin 7 are fixed on the bracket 3, the discharge bin 11 is arranged at the lower part of the feed bin 7, the explosion-proof motor 1 is connected with the transmission gear 12 through the coupling 13; Anti-feeding teeth, the anti-feeding teeth are located on or below the horizontal center plane of the strip roller and the cutting roller, and are used to scrape off the materials stuck on the strip roller or the cutting roller; the cutting roller 5 and the strip roller 9 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com