Powder forming production line and control method

A powder molding and production line technology, applied in the direction of comprehensive factory control, manufacturing tools, presses, etc., can solve the problems of low production efficiency, high safety risk, large number of operators, etc., to improve transfer efficiency, reduce operators, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

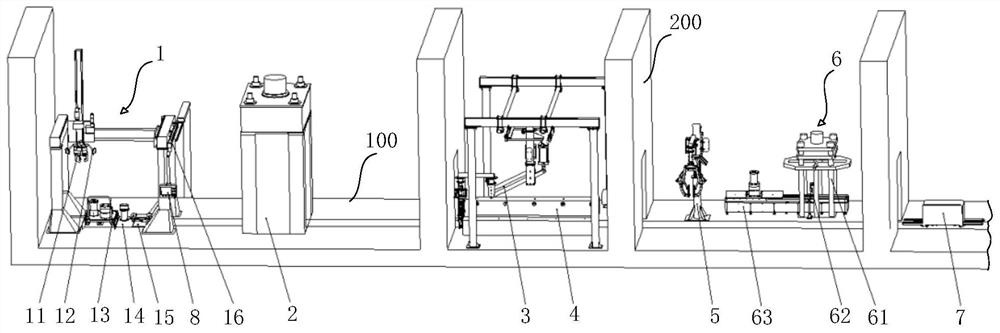

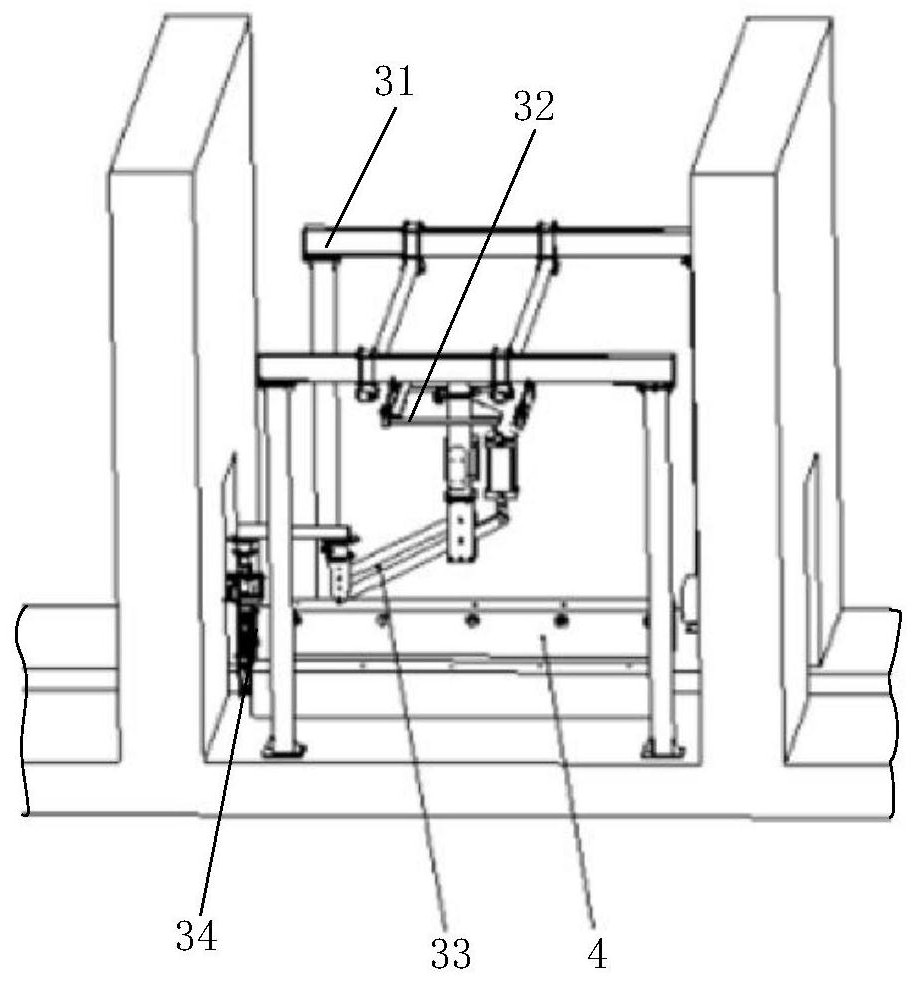

[0046] like figure 1 As shown in the figure, a powder molding production line includes an assembly device 1, a pressing device 2, a cooling device 4 and a mold parting device 6 arranged in sequence along the assembly process, and also includes an assembly device 1, a pressing device 2, and a cooling device. 4. The transport device 7 for transporting the objects with the parting device 6, further comprising a control system 8, the control system 8 is used to realize the automatic operation of the powder molding production line;

[0047] In this embodiment, the assembling device 1 , the pressing device 2 , the cooling device 4 and the parting device 6 are all installed on the mounting seat 100 , and the mounting seat 100 is provided with a slide rail, and the assembling device 1 , the pressing device The device 2, the cooling device 4 and the parting device 6 are arranged above the slide rail; the transport device 7 is moved in the slide rail through the control system 8, the sl...

Embodiment 2

[0082] This example is based on Example 1:

[0083] Both sides of the parting device 6 are provided with an assembling device 1 and a pressing device 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com