Block stone disintegration method based on CO2 liquid-gas phase change

A crushing method and block stone technology, which is applied in the field of rock crushing, can solve the problems of less engineering quantity, impossibility of using blasting methods, and impossibility of using machinery, etc., and achieve the effect of less equipment, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

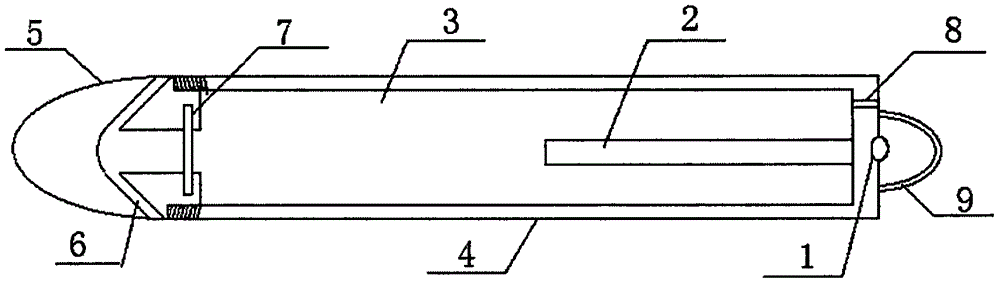

[0071] In an open-pit quarry in Hubei, the rock as a whole is weakly weathered limestone. The blasting parameters used in normal production are: drilling diameter 90mm, step height 20m, hole spacing 4m, row spacing 4.5m, two fully hydraulic crawler drilling rigs drilling, About 5,000 square meters are blasted every day, and the loader loads rocks.

[0072] The rocks after blasting in this quarry are generally large in size, with a maximum size of four meters square. Since the local safety supervision department does not allow the use of explosives for secondary crushing, hydraulic breakers can only be used to break rocks in the mine. The cost of stone crushing is relatively high, which is close to or even exceeds the cost of one blasting, and the efficiency is particularly low.

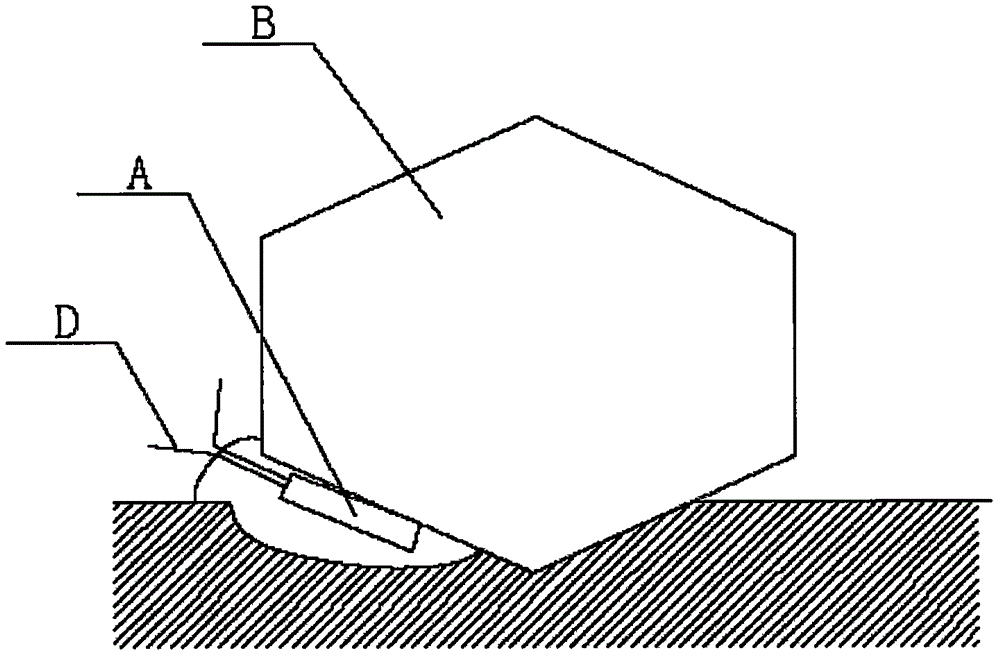

[0073] The use of rock crushing devices based on carbon dioxide phase transition can greatly reduce costs and improve efficiency. According to the operation of the first operation method, one drill d...

example 2

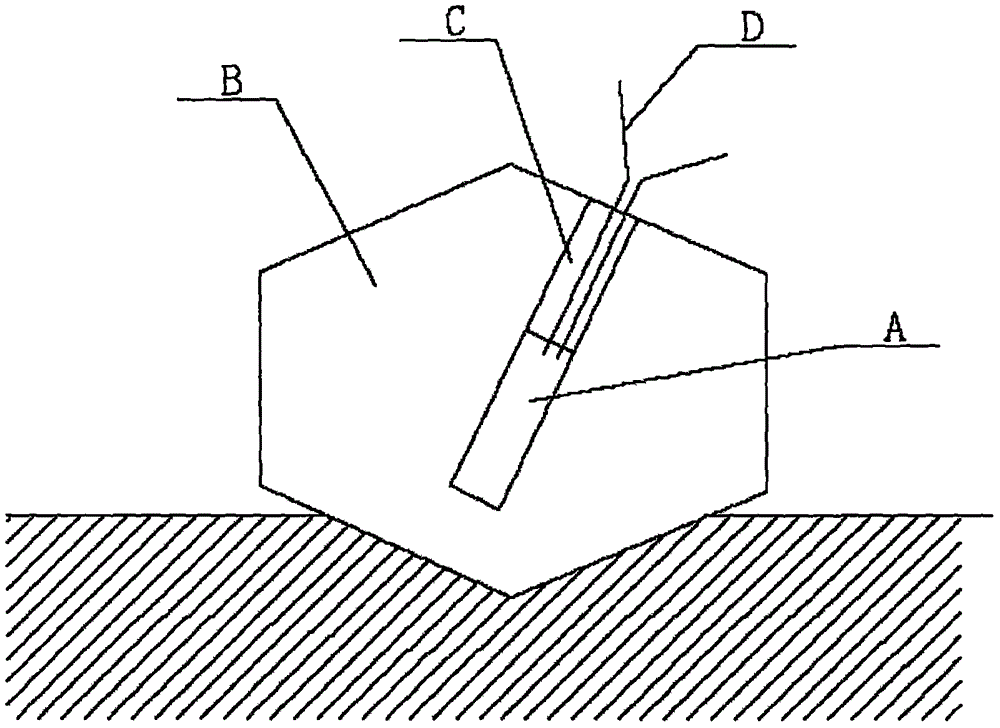

[0075] An earthquake in Sichuan caused a large number of landslides. The only rescue channel - a county-level road was washed away by a large number of stones. Huge boulders blocked the passage, and machinery could not enter to clear the obstacles.

[0076] The rock breaking device based on the carbon dioxide phase change can quickly break the rocks and quickly open the life channel. According to the second operation method, carbon dioxide filling is realized in a safe area, and it is manually carried into the landslide area, and each soldier carries three crushing devices at a time; two soldiers form a group, and one crushing device can be completed every 30 minutes The average crushing volume can reach five cubic meters, and about 120 cubic stone crushing tasks can be completed in 12 hours per day.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com