Automatic pipe cutting machine

A pipe cutting machine and automatic technology, which is applied to pipe shearing devices, shearing devices, accessories of shearing machines, etc., can solve the problems of increasing production costs and other problems, and achieve convenient cutting length adjustment, wide application range and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

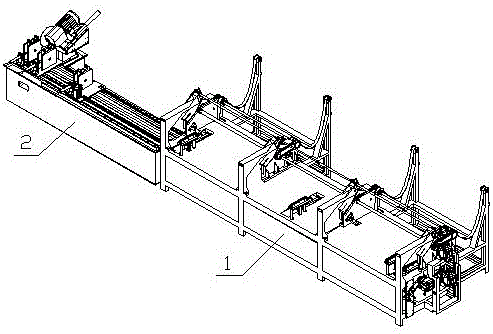

[0058] Embodiment: a kind of automatic pipe cutting machine, as figure 1 As shown, it includes a feeding mechanism 1, a pipe cutting mechanism 2 and a control system. The feeding mechanism 1 is arranged at the rear of the pipe cutting mechanism 2, and supplies the pipe material to be cut for the pipe cutting mechanism 2.

[0059] In this embodiment, the automatic pipe cutting machine also includes a blanking mechanism (not shown in the figure), which is arranged in front of the pipe cutting mechanism 2, and the control system controls the blanking mechanism, the pipe cutting mechanism 2 and the feeding mechanism. Collaborative work of Agency 1.

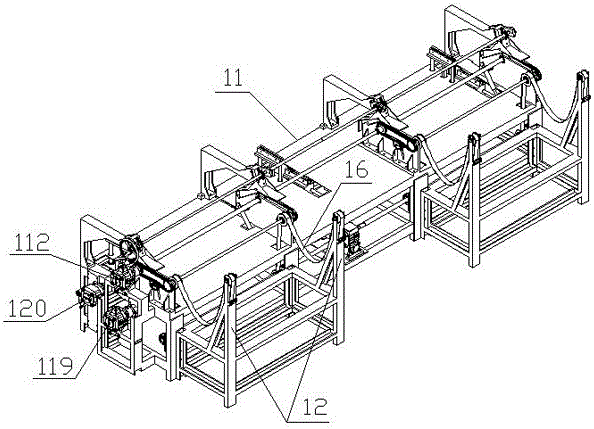

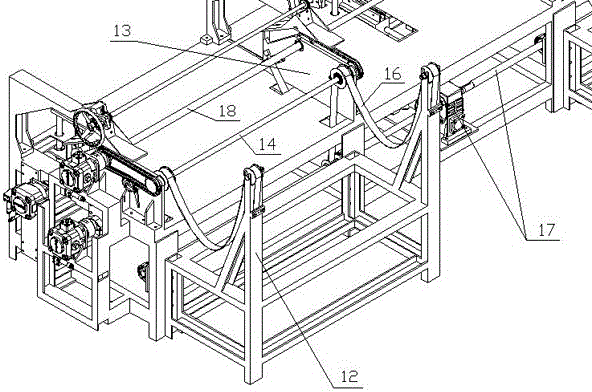

[0060] Such as Figure 2~5 As shown, the feeding mechanism 1 includes a frame 11, a plurality of support columns 12 are arranged on the right side of the frame 11, and a plurality of mechanism mounting plates 13 are arranged in parallel on the left side of the frame 11. Mechanism mounting plate 13 is provided with rotating shaft on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com