A high dimensionally stable sn‑ag‑cu solder for electronic packaging

A technology of dimensional stability and electronic packaging, applied in the direction of welding/cutting media/materials, welding media, welding equipment, etc., can solve the problems of poor dimensional stability, ultra-fine pitch microelectronic packaging performance can not meet the requirements, etc., to achieve dimensional stability Good performance, excellent comprehensive service performance, and the effect of improving the elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

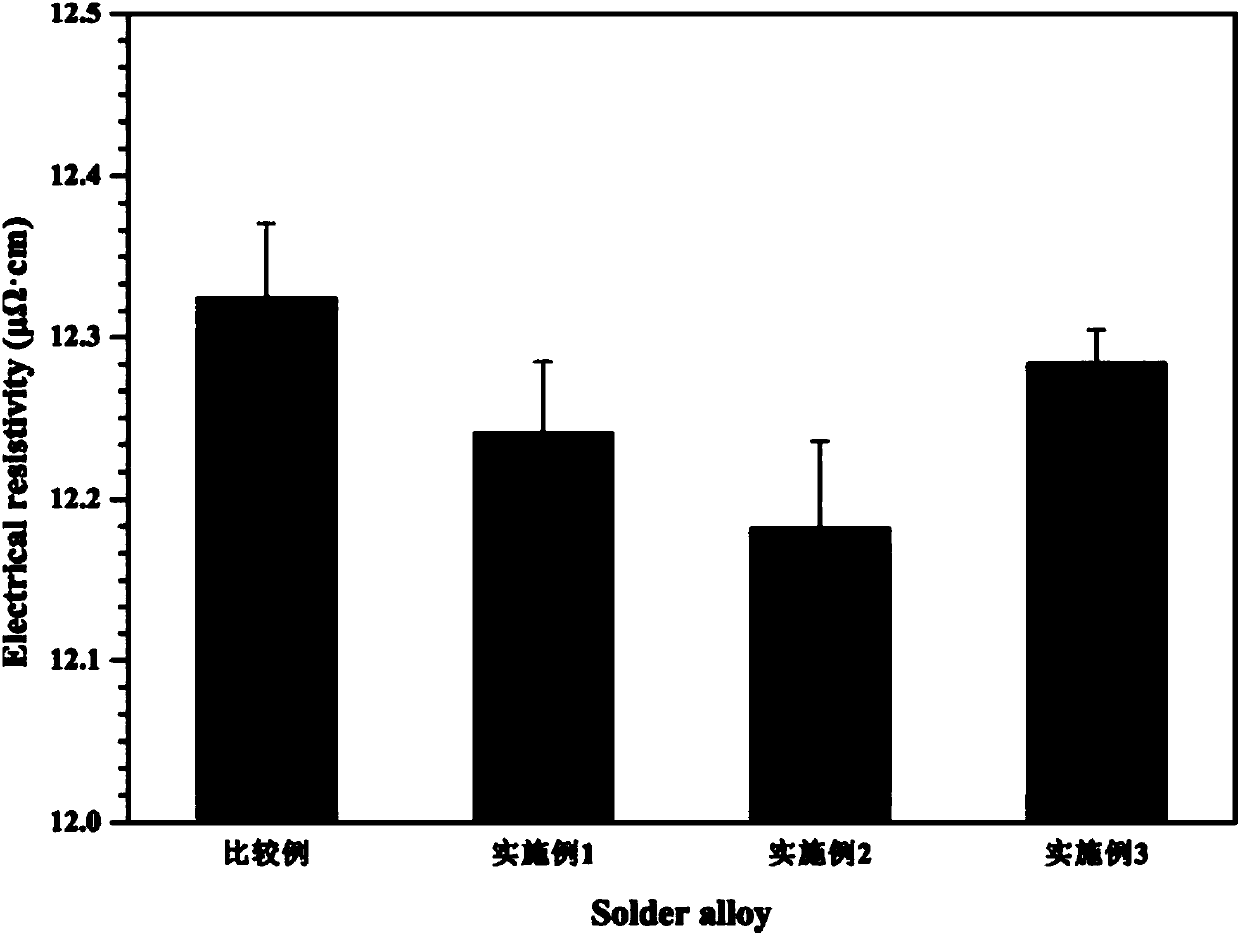

Embodiment 1

[0042] Example 1 Sn-3.0Ag-0.5Cu-0.1Be

[0043] The weight percentage of each component of the solder is: Ag is 3.0%, Cu is 0.5%, Be is 0.1%, and the balance is Sn.

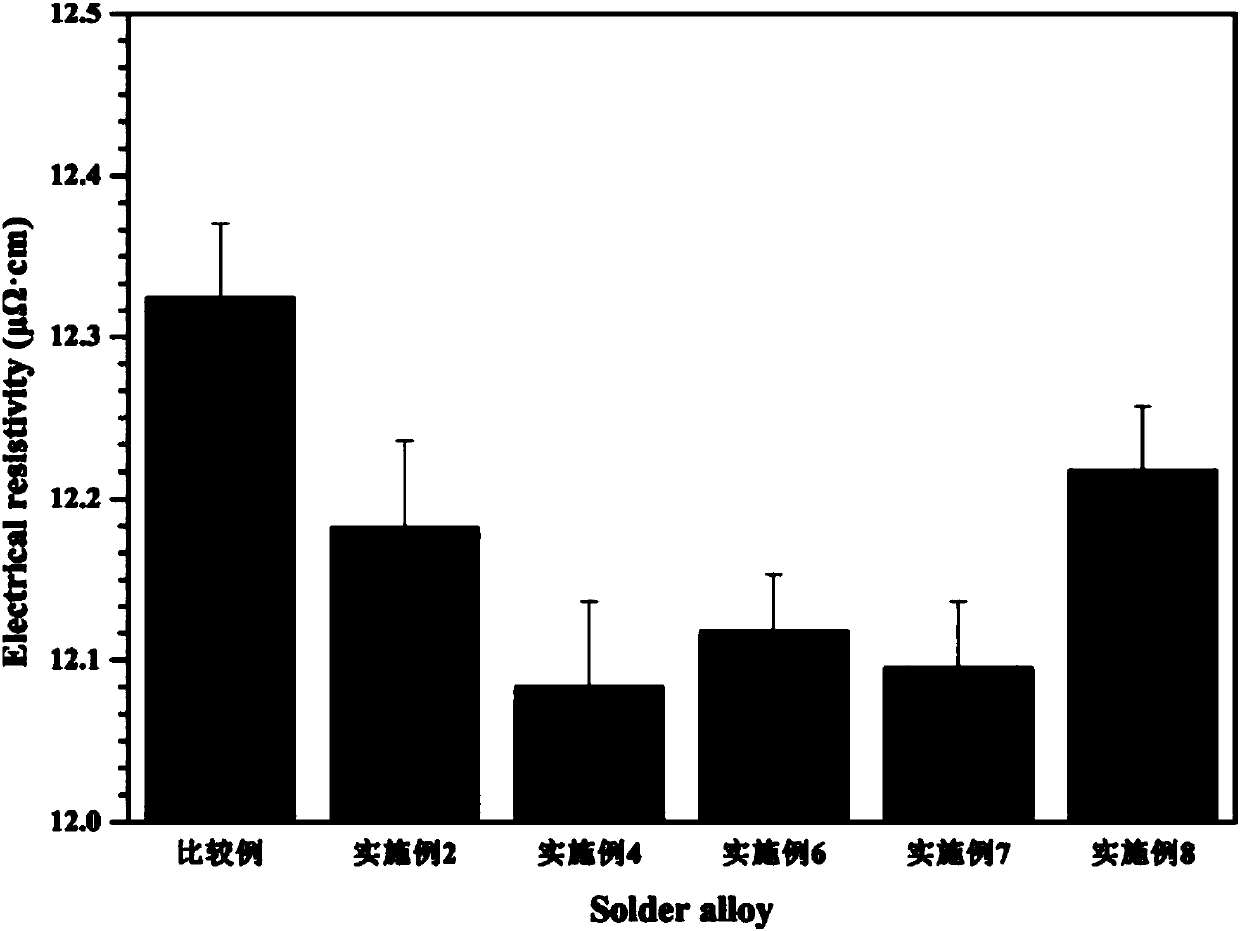

Embodiment 2

[0044] Example 2 Sn-3.0Ag-0.5Cu-0.2Be

[0045] The weight percentage of each component of the solder is: Ag is 3.0%, Cu is 0.5%, Be is 0.2%, and the balance is Sn.

Embodiment 3

[0046] Example 3 Sn-3.0Ag-0.5Cu-0.5Be

[0047] The weight percentage of each component of the solder is: Ag is 3.0%, Cu is 0.5%, Be is 0.5%, and the balance is Sn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com