Tool for fast mounting and demounting LD die bar and elastic piece and use method of tool

A die strip and shrapnel technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as affecting product quality, slowing down the process of die strip loading and unloading, and small applicability, so as to improve work efficiency and work efficiency. Quality, reduce skew and contamination, resolve the effect of operating inconsistencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

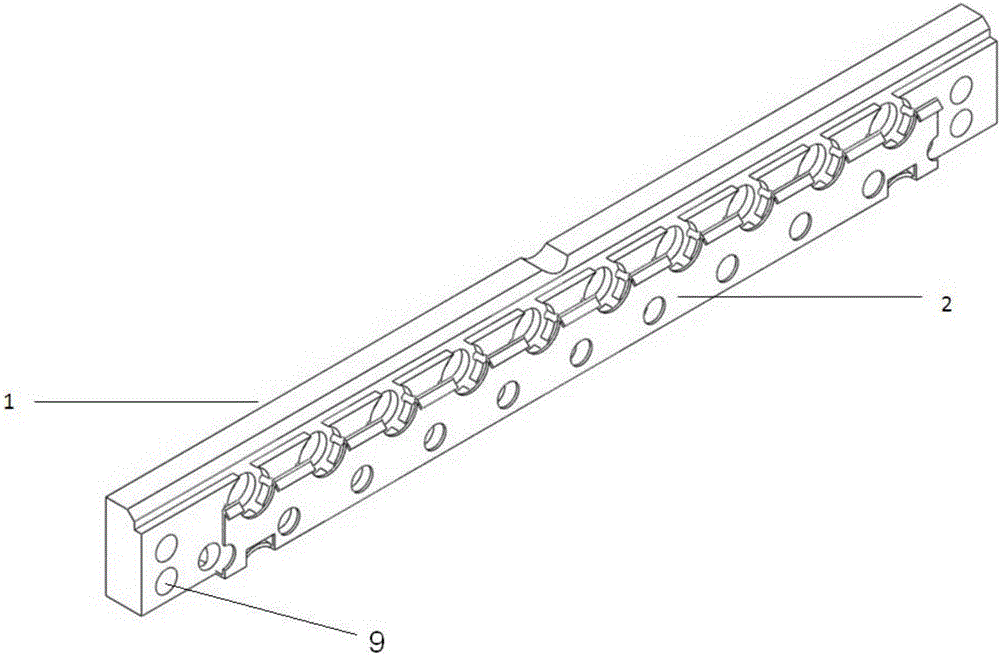

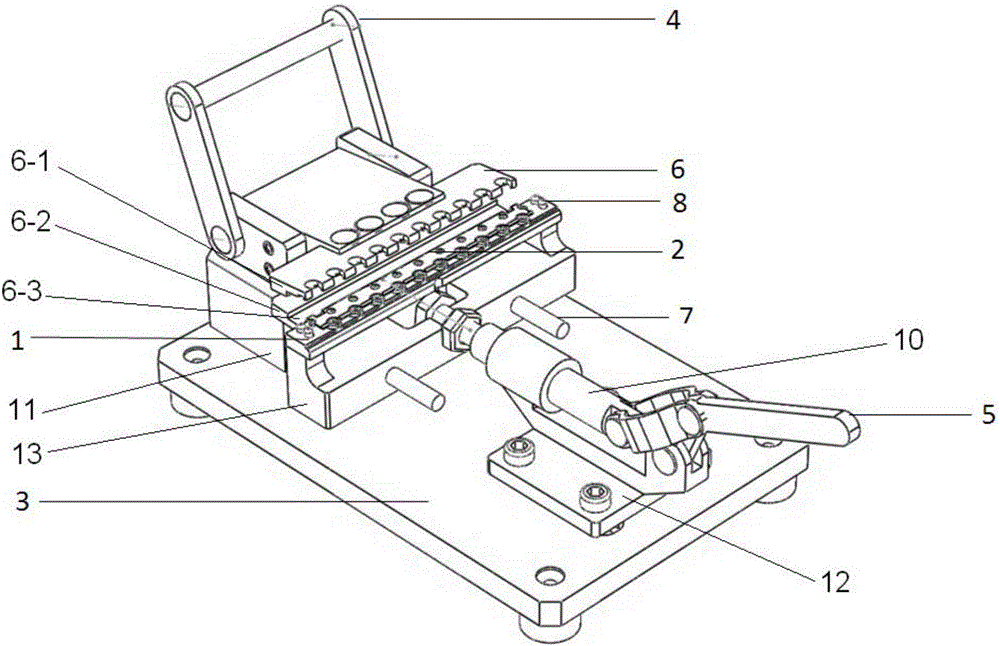

[0036] A tooling for fast loading and unloading of LD mold strips and shrapnel, including a base, a left rocker arm fixed base and a movable seat on the base, a left rocker arm, a mold strip loading and unloading clip are arranged on the left rocker arm fixed base, and the left rocker arm controls The mold bar loading and unloading clamps are clamped and opened, and the left rocker arm is provided with a guide rail on one side of the fixed base, and the mobile seat is provided with a track that matches and connects with the guide rail. The mold strip is placed on the moving seat, and the mold strip is driven by the moving seat to move to the mold strip loading and unloading clamp, and the mold strip and the shrapnel are clamped by the left rocker arm to control the mold strip loading and unloading clamp.

[0037] The tooling described in this embodiment is mainly used for loading and unloading mold strips and shrapnel. The mold strip and shrapnel are an independent tooling fixt...

Embodiment 2

[0039] A kind of tooling for fast loading and unloading of LD mold strips and shrapnel, its structure is as described in Embodiment 1, the difference is that the base is also provided with a right rocker arm fixing base, such as figure 2As shown, the right rocker arm fixed base is provided with a right rocker arm and a guide post, the right rocker arm is connected with the guide post, and the guide post is connected with the mobile seat. The left and right swing of the right rocker arm drives the guide post to move back and forth, and the guide post is connected to the movable seat, so that the movable seat can move horizontally, making the movable seat move back and forth more conveniently.

Embodiment 3

[0041] A tool for quick loading and unloading of LD mold strips and shrapnel, its structure is as described in Embodiment 2, the difference is that the fixing base of the right rocker arm is connected with the base by screws. It is convenient to replace parts and adjust spacing, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com