Mixing and dust-sucking device for producing anti-radiation dry powder mortar

A technology of dry powder mortar and dust collection device, which is applied in the direction of selling raw material supply device, mixing operation control device, clay preparation device, etc., which can solve the problems of inconvenient discharge, excessive dust, uneven mixing, etc., and reduce the cost of equipment wear, reduce air pollution, good production continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

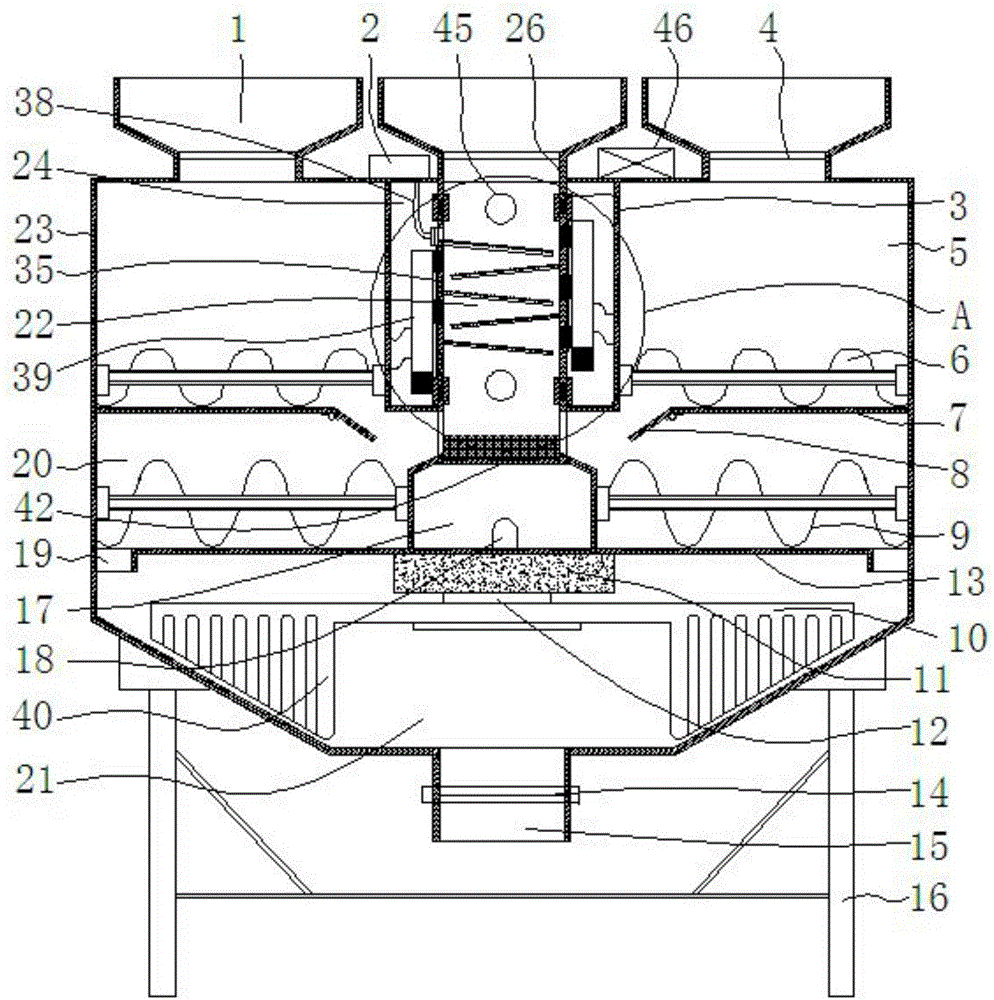

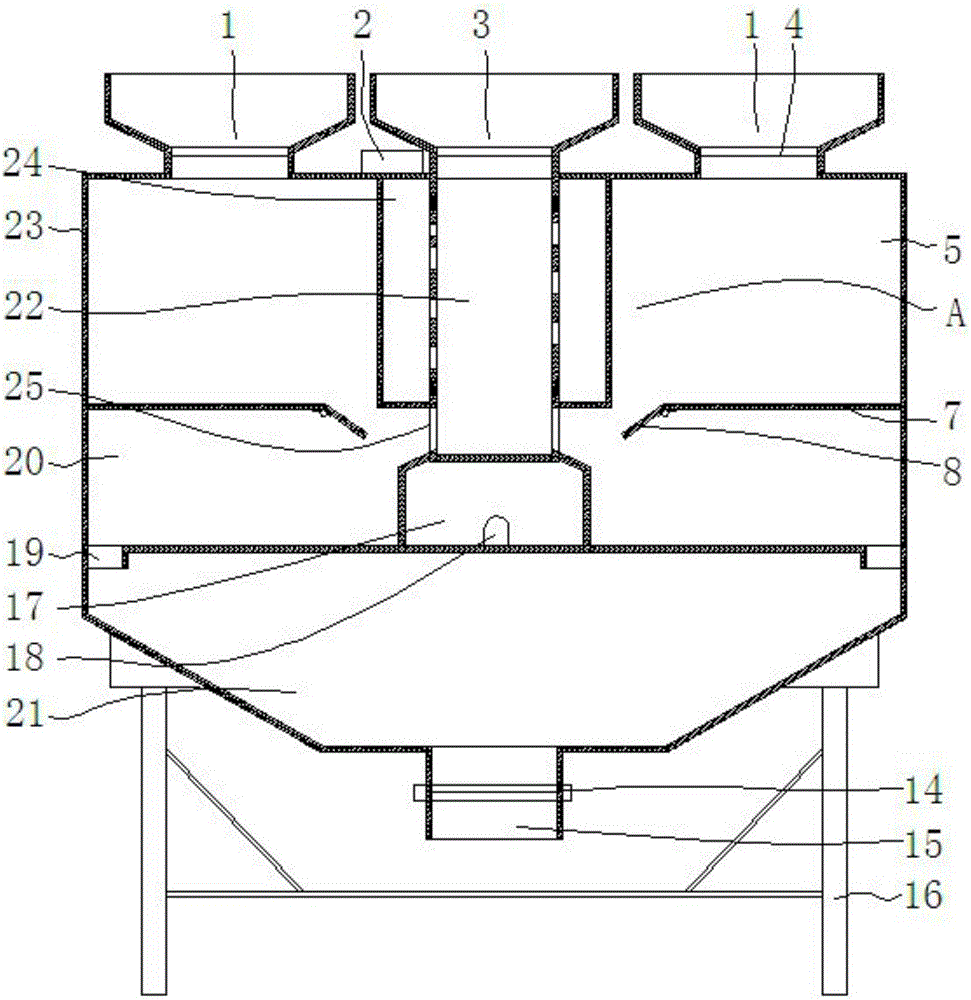

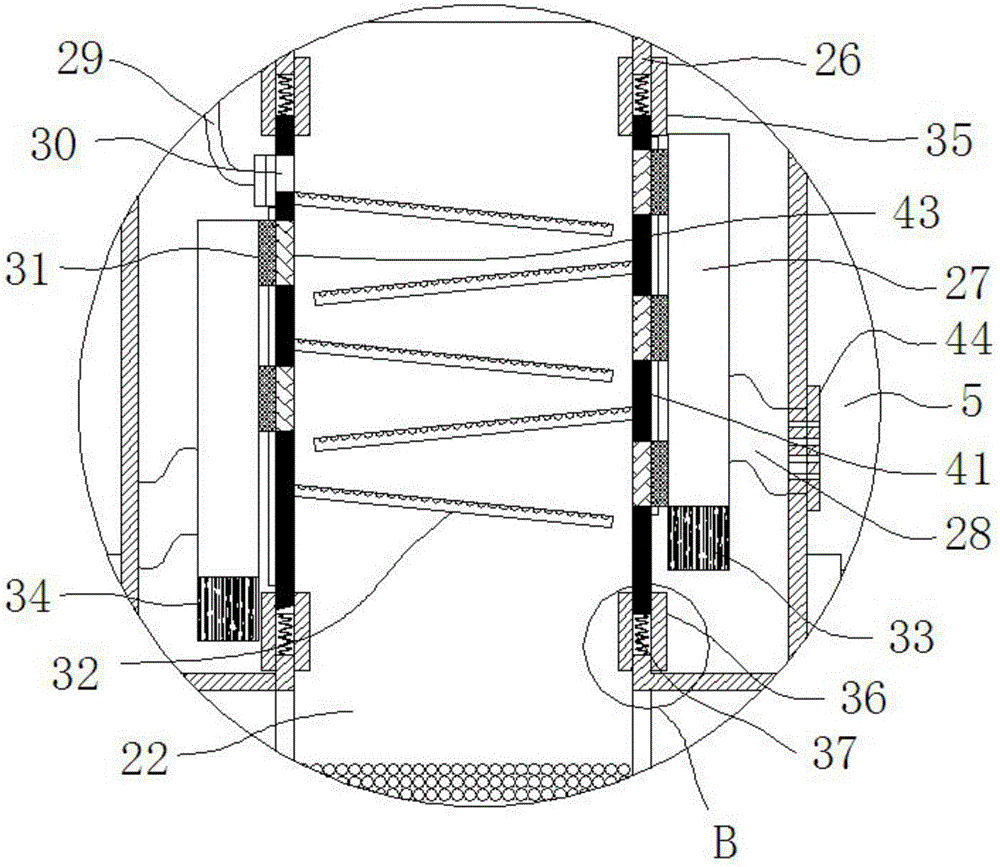

[0026] Such as Figure 1-Figure 6Shown, the concrete structure of the present invention is: it comprises frame 13, and its upper end is provided with organic body 23; Said body 23 is provided with coagulation chamber main body 26; Described coagulation chamber main body 26 is provided with shot ball coagulation chamber 22; The outer end of the shot coagulation chamber 22 is provided with a spacer 3; the interior of the spacer 3 is a vibration chamber 24; the left and right sides of the vibration chamber 24 are provided with a combined raw material feeding chamber 5; the lower end of the combined raw ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com