Cover material and packaging container

一种基材、树脂的技术,应用在食品类包装用容器的热封盖材料,具有该盖材料的包装容器领域,能够解决防附着效果消失、填充粒子脱落、填充粒子粘接强度不充分等问题,达到可靠疏水功能、高防附着功能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

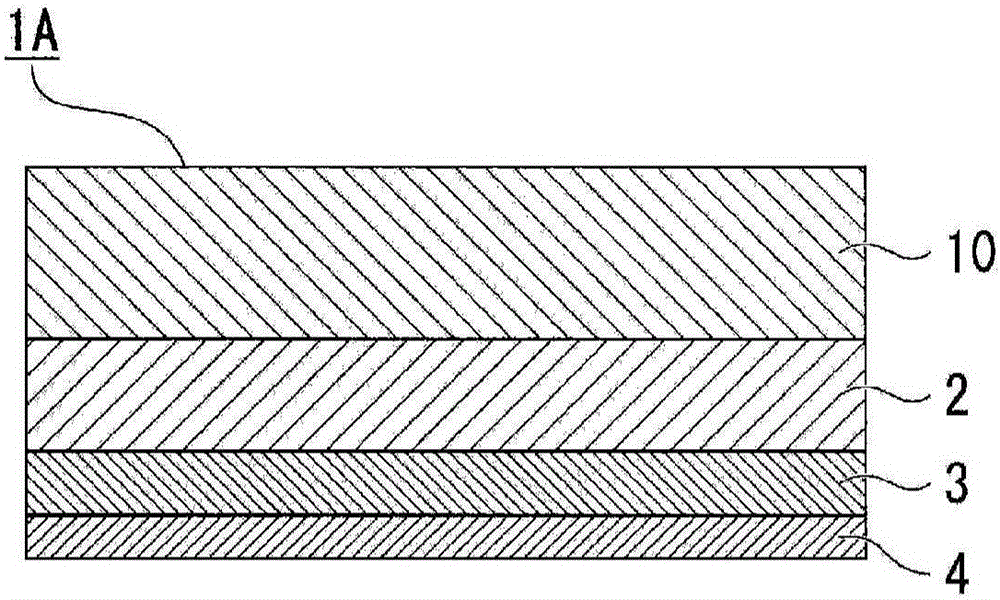

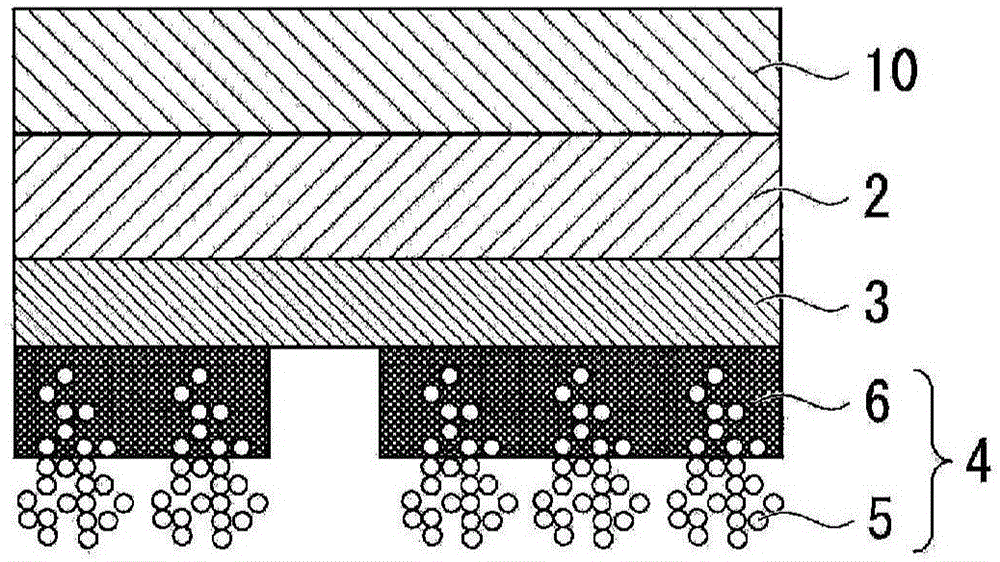

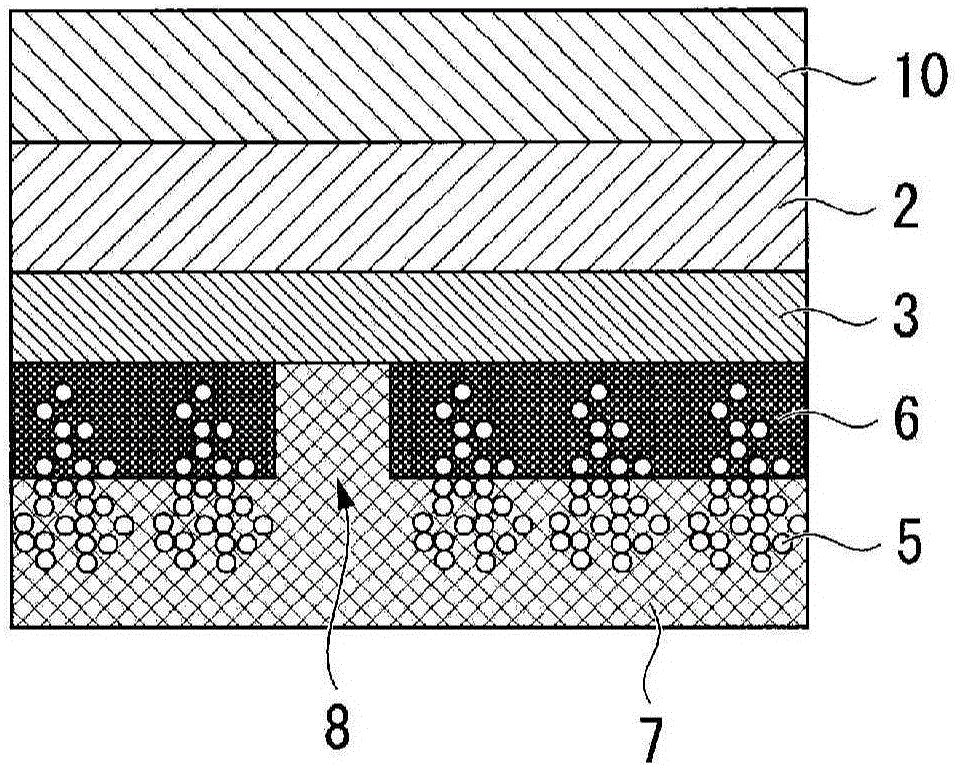

[0067] figure 1 It is a sectional view showing an example of the layer structure of the lid material of the present invention. In the lid material 1A, a base material layer 10 (base material), an inorganic vapor-deposited film 2 , and a sealant layer 3 are laminated from the outside (the outside of the packaging container to which the lid material is bonded). An antiadhesive layer 4 for preventing the contents from adhering to the lid material 1A is formed on the innermost layer of the lid material joining the packaging container, that is, on the surface facing the contents packed in the packaging container.

[0068] As the substrate layer 10, films such as paper, polyethylene terephthalate resin, stretched olefin resin such as polyethylene and polypropylene, polyamide resin, polyvinyl chloride resin, cellulose acetate, cellophane, etc. can be used. , or a laminate made of these materials, or the like. In addition, secondary processing such as printing, vapor deposition, and...

no. 2 approach

[0086] Below, refer to Figure 4 with Figure 5 A second embodiment of the present invention will be described.

[0087] Figure 4 It is an enlarged cross-sectional view showing a cover material 1B of the second embodiment. The cover material 1B has: a base material 10 (base material layer), a concave-convex layer 20 formed on the base material 10, a sealant layer 30 (thermoplastic resin layer) made of a thermoplastic resin formed on the concave-convex layer 20, The anti-adhesion layer 40 (hydrophobic functional layer) arranged on the layer 30.

[0088] The material of the substrate 10 is not particularly limited as long as the resin contained in the concave-convex layer 20 is sufficiently bonded, and it is not particularly limited. For example, paper, plastic film, aluminum foil, and the like can be used. As the paper, fine paper, special fine paper, coated paper, art paper, cast coated paper, molded paper (simili paper), kraft paper and the like can be used. As the plas...

Embodiment 1

[0126]As the substrate layer, the thickness of 52.3g / m 2 The molded paper is laminated with an aluminum-evaporated polyethylene terephthalate film with a thickness of 16 μm. On the surface of the aluminum vapor-deposited polyethylene terephthalate film of the bonded laminated body, a primer layer is also coated. Curing type thermosetting resin formed. Then, a varnish-type sealant layer containing polyacrylate as a main component was further coated on the primer layer.

[0127] In the anti-adhesion layer, tetraethoxysilane Si(OC 2 h 5 ) 4 The hydrolyzed solution is fully mixed with the hydrophobic particle 5 dispersion liquid dispersed with alcohol, adjusted so that the solid content of the coating solution reaches 10%, and the adjusted coating solution is coated on the sealant layer, and then Drying forms an anti-adhesive layer.

[0128] In the antiadhesive layer 4, when the ratio between the metal oxide conversion amount of the metal alkoxide or its hydrolyzate as the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com