Slurry reduction treatment system

A treatment system and reduction technology, used in sludge treatment, water/sludge/sewage treatment, dewatering/drying/concentrated sludge treatment, etc. Abnormal and other problems, to achieve the effect of ensuring the separation effect and the effect of being conducive to the formation of pile holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

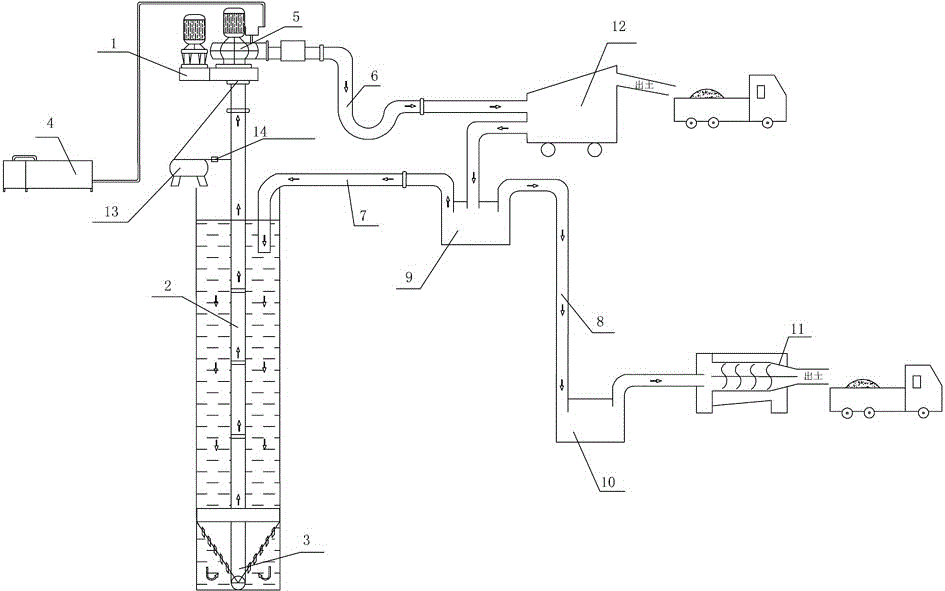

[0026] Embodiment one: see figure 1 As shown, a mud reduction treatment system is composed of a mud extraction device, a mud removal and purification device, and a chemical treatment device connected in sequence.

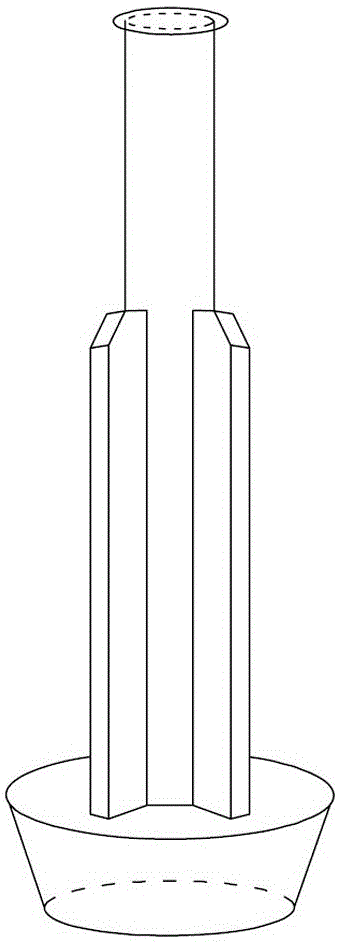

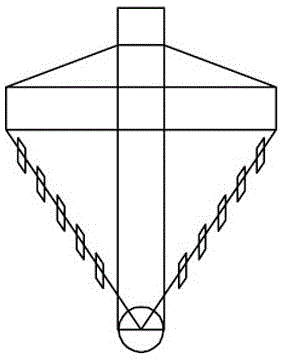

[0027] see figure 1 , the mud pumping device includes a high-torque power unit 1, a large-diameter hollow drill pipe 2, a scraper drill bit 3, a vacuum pump 4, a dredge pump 5, a reducer 14, a hoist 13, and a mud discharge pipe 6. The power unit 1 Drive the hollow drill pipe 2 to rotate, the hoist 13 cooperates with the reducer 14 to drive the hollow drill pipe 2 to move up and down, the inlet of the dredge pump 5 is connected to the inner cavity of the hollow drill pipe, and the outlet of the dredge pump 5 passes through the mud discharge pipe 6 Connect to the feed port of the desilting and purifying device. see figure 2 , in order to make the operation stable, the hollow drill rod is provided with a counterweight. see image 3 , the scraper bit is provided w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com