Aqueous nano-antibacterial sound absorption coating and preparation method thereof

A sound-absorbing paint, water-based technology, applied in the field of paint, can solve the problems of discoloration, peeling, and chalking of the coating film, and achieve the effect of good sound-absorbing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

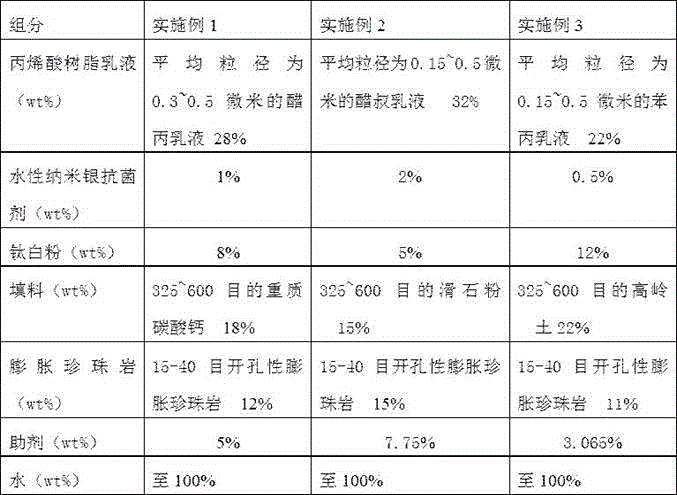

Embodiment 1~3

[0029]

[0030] In the above embodiments, the auxiliary agents are 0.3-0.5% defoamer, 0.1-0.2% wetting agent, 0.25-1.0% thickener, 0.4-0.8% rheological agent, 0.4-0.6% anti-mold agent, pH adjustment 0.1% to 0.15% of dispersant, 0.5 to 1.0% of dispersant, 1.5 to 2% of humectant, 1.0 to 1.5% of film forming aid. The thickener is hydroxyethyl cellulose or organic bentonite thickener.

[0031] The water-based nano silver antibacterial agent used in the examples is a commercially available product.

[0032] The above examples were prepared according to the following preparation method:

[0033] (1) Pre-mixing: add half of the water needed to make the paint, water-based nano silver antibacterial agent, dispersant, wetting agent, 1 / 2 defoamer, anti-mold agent, thickener, and PH value regulator into the dispersion In the tank, stir for 15-25 minutes at a stirring speed of 300-500 rpm to form a jelly-like fluid.

[0034] (2) Dispersion: Add titanium dioxide and filler to the fluid prepared i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com