A kind of water-based paint and its preparation method and application method

A water-based paint and coating technology, applied in the direction of polyurea/polyurethane paint, coating, etc., can solve the problem of water resistance, acid and alkali resistance of closed coatings, poor physical and tender indicators, easy to exceed chemical volatile substances, and poor process. Environmental protection and other issues, to achieve the effect of keeping the appearance for a long time, beautiful appearance, simple manufacturing method and use method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

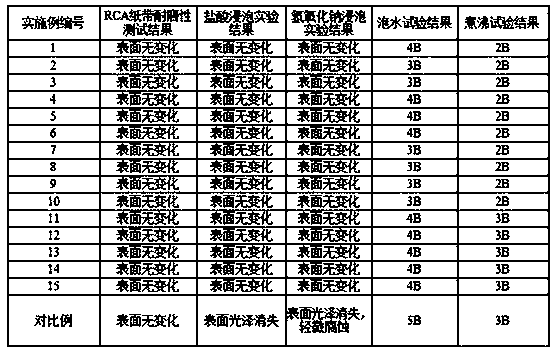

Examples

Embodiment Construction

[0028] The content of the present invention is further described below by way of examples.

[0029] 1. Preparation of water-based polyurethane / water-based acrylate composite emulsion

[0030] In practical applications, it is advisable to choose water-based polyurethane emulsion and water-based acrylate emulsion with the same percentage of solids, so as to control the ratio of solid content. The ratio of solid content in the emulsion can be adjusted according to the application field, and further adjust the viscosity and film-forming performance of the final coating. the goal of. In this embodiment, the water-based polyurethane emulsion and the water-based acrylate emulsion with a solid content of 35% are selected, and the volume ratios are 1:1.2, 1:1.35, 1:1.4, 1:1.55, 1:1.7, 1:2.2, Mix 1:2.45, 1:2.5, 1:2.7, 1:3, stir evenly and grind until the solid particle size is less than 50μm, and then disperse in a high-speed disperser at a dispersing speed of 1500r / min for 0.5 hours. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com