Polyisobutylene modified building asphalt and preparation method thereof

A technology of polyisobutylene and building asphalt, which is applied in the direction of construction, building components, building structures, etc., can solve the problems of high low-temperature brittleness, thermodynamic instability, and long-term process, so as to improve the performance of high and low temperature resistance and avoid ineffectiveness. Obvious and economical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

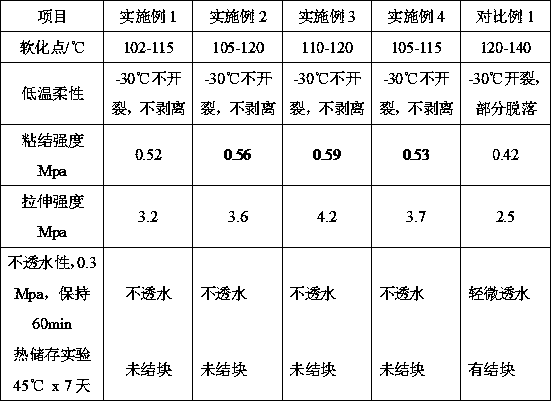

Examples

Embodiment 1

[0040] A polyisobutylene modified construction asphalt is composed of the following components by weight:

[0041] Basic asphalt 100 parts

[0042] 10 parts of epoxy polyisobutylene

[0043] lignin 5 parts

[0044] Inorganic filler 50 parts

[0045] Silane coupling agent 1 part

[0046] Anti-aging agent 0.5 parts

[0047] The base asphalt is selected from straight-run petroleum asphalt.

[0048] The inorganic filler is selected from 15 parts of magnesium hydroxide, 20 parts of barium sulfate and 15 parts of calcium carbonate.

[0049] The silane coupling agent is selected from aminosilane coupling agents, selected from 3-aminopropyltriethoxysilane.

[0050] The anti-aging agent is selected from phenolic antioxidants.

[0051] The preparation method of this polyisobutylene modified construction asphalt is:

[0052] 1) Add magnesium hydroxide, barium sulfate, and calcium carbonate to the planetary grinder, and add ethanol / water (50 / 50

[0053]parts by mass), then add an...

Embodiment 2

[0059] A polyisobutylene modified construction asphalt is composed of the following components by weight:

[0060] Basic asphalt 100 parts

[0061] 20 parts of epoxy polyisobutylene

[0062] Lignin 7.5 parts

[0063] Inorganic filler 60 parts

[0064] 1.5 parts of silane coupling agent

[0065] Anti-aging agent 1 part

[0066] The base asphalt is selected from straight-run petroleum asphalt.

[0067] The inorganic filler is selected from 20 parts of magnesium hydroxide, 20 parts of barium sulfate and 20 parts of calcium carbonate.

[0068] The silane coupling agent is selected from aminosilane coupling agents, selected from 3-aminopropyltriethoxysilane.

[0069] The anti-aging agent is selected from phenolic antioxidants.

[0070] The preparation method of this polyisobutylene modified construction asphalt is:

[0071] 1) Add magnesium hydroxide, barium sulfate, and calcium carbonate to the planetary grinder, and add ethanol / water (50 / 50

[0072] parts by mass), then ...

Embodiment 3

[0078] A polyisobutylene modified construction asphalt is composed of the following components by weight:

[0079] Basic asphalt 100 parts

[0080] 30 parts of epoxy polyisobutylene

[0081] lignin 10 parts

[0082] Inorganic filler 80 parts

[0083] 3 parts of silane coupling agent

[0084] Anti-aging agent 2 parts

[0085] The base asphalt is selected from straight-run petroleum asphalt.

[0086] The inorganic filler is selected from 25 parts of magnesium hydroxide, 25 parts of barium sulfate and 30 parts of calcium carbonate.

[0087] The silane coupling agent is selected from aminosilane coupling agents, selected from 3-aminopropyltriethoxysilane.

[0088] The anti-aging agent is selected from phenolic antioxidants.

[0089] The preparation method of this polyisobutylene modified construction asphalt is:

[0090] 1) Add magnesium hydroxide, barium sulfate, and calcium carbonate to the planetary grinder, and add ethanol / water (50 / 50

[0091] parts by mass), then ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com