Sealed door filed airtight test method and test device

A test device and a closed door technology, which can be used in the use of liquid/vacuum for liquid tightness measurement, by measuring the acceleration and deceleration rate of the fluid, and by detecting the appearance of the fluid at the leak point, etc., which can solve the inconvenience of transportation and handling. Safety hazards, processing difficulties and other problems can shorten the test preparation time, facilitate portability and transportation, and reduce the test cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1 (the airtight door is a rectangular structure)

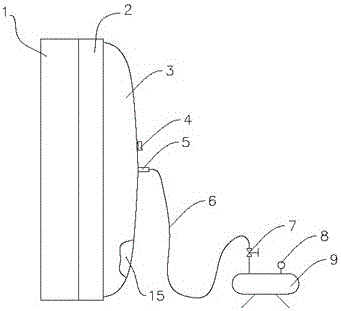

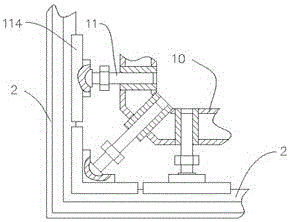

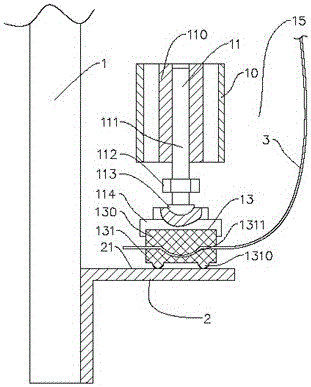

[0063] See attached figure 2 , a kind of test device of the method for realizing the on-site airtightness test of the airtight door according to the first embodiment of the present invention, which consists of a rigid frame, a pressing mechanism 11, a gasket 13, and an air pressure cavity 15 formed with the door frame 2 and the door leaf 1 The closed membrane is composed of 3.

[0064] The rigid frame is a rectangular frame 10 corresponding to the rectangular door frame 2. It is located in the inner cavity of the door frame 2. There is a gap between the rigid frame and the inner side of the door frame 2. The pressing mechanism 11 is distributed along the rigid frame and expands and contracts to the outside of the rigid frame. , the gasket 13 is an annular structure that is laid along the inner side of the door frame 2, and the surrounding edge of the sealing diaphragm 3 is placed into the gasket 13; .

[...

Embodiment 2

[0074] Embodiment 2 (the airtight door is a circular structure)

[0075] See attached Figure 7 , 8 And attached Figure 9 , as a modification, the difference between the second embodiment and the first embodiment is that the rigid frame is an annular frame 23 corresponding to the door frame 21. The three sections of arc-shaped rods 233 are assembled through butt joints. Corresponding spherical grooves 231 and spherical protrusions 230 are arranged between the two opposite sections of the joints. After butt joints, a complete ring is formed. When the circular door frame 21 When the diameter is larger, the rigid frame 23 can also be decomposed into more than 3 sections of circular arc butt joint assembly, and in order to avoid the deformation of the circular frame 23 during use, multiple a radial support rod. Equally, the profile of sealing gasket 24, sealing diaphragm 22 is a ring shape, and the pressing mechanism 11 is distributed along the outer circumference of the annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com