Simplified progressive failure analysis method for ultimate longitudinal strength of ship

A technology of ultimate strength and damage analysis, applied in the field of ships, it can solve the problems of not calculating the load response and limit value, and unable to accurately know the safety margin of the hull, so as to improve the applicability and accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

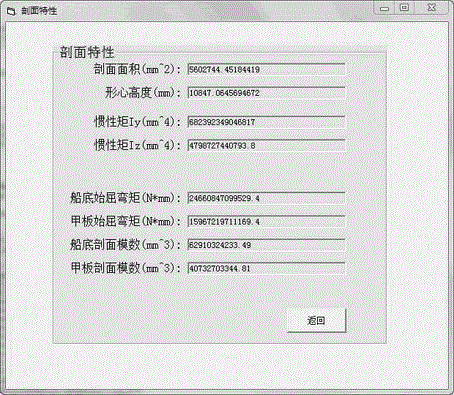

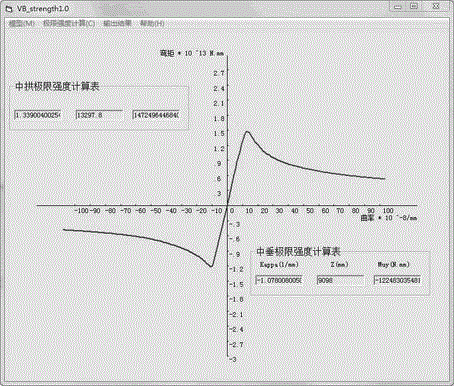

[0065] Calculation of longitudinal ultimate strength of a large bulk carrier.

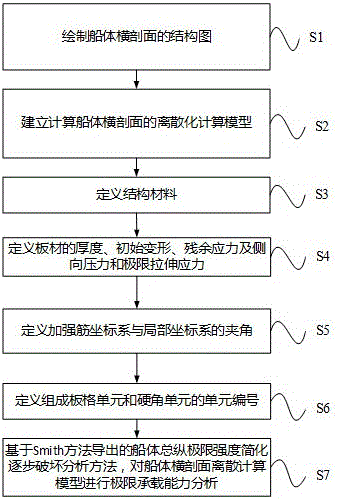

[0066] Step S1, drawing a cross-sectional view, specifying the model parameters, see the appendix of the manual for the drawing figure 2 .

[0067] Step S2, divide the cross-section of the model

[0068] The connection point of the plate and the plate, the connection point of the rib and the plate is regarded as a node, the joint of the plate and the plate is regarded as a hard corner unit, and the position with a stiffener is regarded as a plate lattice unit. See the attached Figure 3-6 , the model has 113 nodes, 120 plate elements, 94 stiffened plates, and 19 hard corner elements. Simplify the bilge part of the hull into a hard corner unit, and simplify the arc structure of the connecting part of the deck and side into a stiffened plate unit.

[0069] Step S3, defining the structural material, including yield limit, Young's modulus and Poisson's ratio.

[0070] In this example, there is only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com