Novel corrosion-resistance flexible fireproof photoelectric composite cable

A photoelectric composite and composite cable technology, which is applied in the direction of power cables, power cables including optical transmission components, insulated cables, etc., can solve the problems of complex manufacturing process, high price, low market acceptance, etc., and achieve the effect of excellent fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

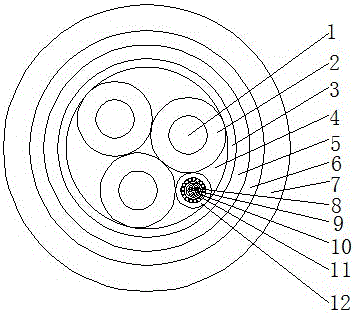

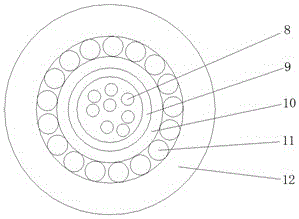

[0019] As shown in the figure, the novel corrosion-resistant flexible fireproof photoelectric composite cable of the present invention includes 2 to 5 insulated wire cores and an optical fiber core twisted into a composite cable core; The insulating layer 2; the optical fiber core includes an optical fiber 8 from the inside to the outside, and the optical fiber metal protection tube 9 is continuously welded outside the optical fiber 8, the metal protection tube 9 is filled with lubricating petroleum jelly, and the metal protection tube 9 is extruded with high-density polyethylene Ethylene optical f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| change rate of elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com