Lithium battery separator with thermal switch function and preparation method of lithium battery separator

A lithium battery diaphragm and thermal switch technology, which is applied to battery pack components, separators/films/diaphragms/spacers, circuits, etc., can solve problems affecting lithium battery capacity, low diaphragm safety, and difficult recovery of micropores, etc. problems, to achieve the effect of low cost, excellent safety performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

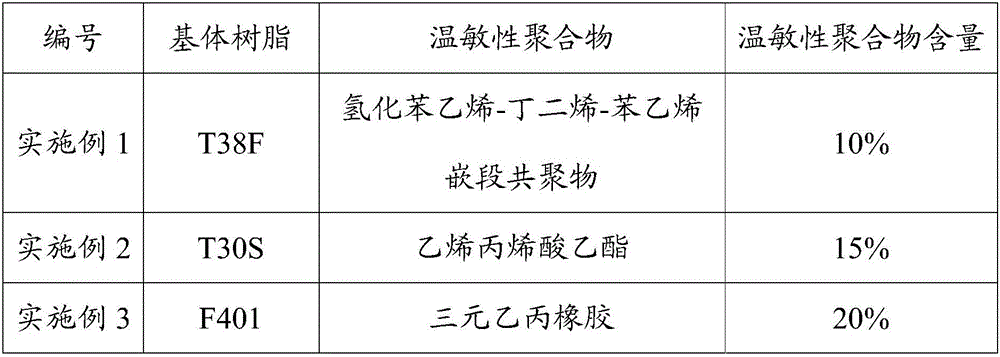

Embodiment 1

[0035] The matrix resin is homopolypropylene T38F produced by Lanzhou Petrochemical (melting index: 3.0g / 10min; melting point: 165°C) and 10wt% of temperature-sensitive polymer additive hydrogenated styrene-butadiene-styrene block copolymer Melt compounding in a twin-screw extruder. The melt is extruded through a slit-shaped die and cooled by a chilled roll to obtain a polypropylene base film. The temperature of the chilled roll is 80° C., and the cooled polypropylene base film is folded flat by a traction roll. The polypropylene base film was first stretched longitudinally along the extrusion direction at a stretching temperature of 70°C and a stretching ratio of 2.0; then transversely stretched at a stretching temperature of 90°C and a stretching ratio of 2.0.

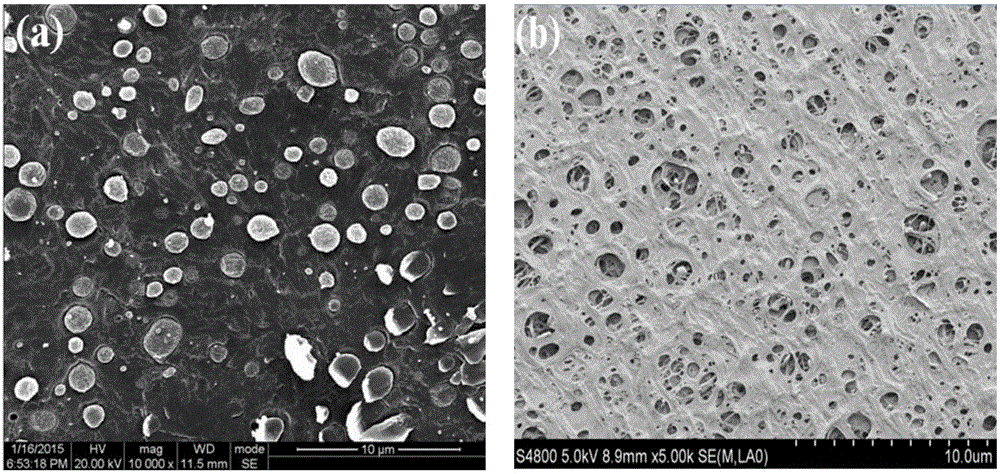

[0036] The results of scanning electron microscopy of the section of the polypropylene base film prepared by this method are as follows: figure 1 As shown in a, it can be seen that the added thermosensitive polymer ...

Embodiment 2

[0039] The matrix resin is homopolypropylene T30S (melt index: 3.5g / 10min; melting point: 167°C) produced by Daqing Petrochemical Co., Ltd. and 15wt% temperature-sensitive polymer additive ethylene ethyl acrylate, which is melt-mixed in a twin-screw extruder. The melt is extruded through a slit-shaped die and cooled by a chilled roll to obtain a polypropylene base film. The temperature of the chilled roll is 70° C., and the cooled polypropylene base film is folded flat by a traction roll. The polypropylene base film was first stretched longitudinally along the extrusion direction at a stretching temperature of 80°C and a stretching ratio of 2.5; then transversely stretched at a stretching temperature of 100°C and a stretching ratio of 2.5.

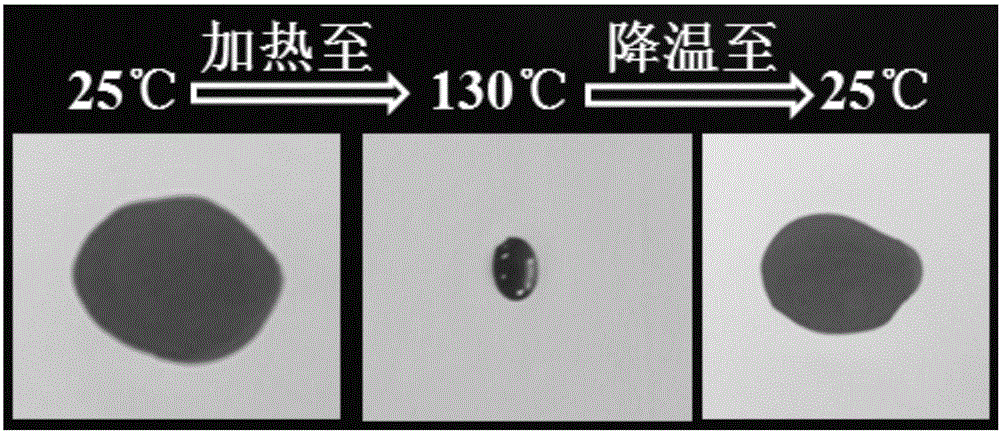

[0040] The lithium battery diaphragm prepared by the method has excellent pore size distribution uniformity, a porosity of 46%, and a Gurley value of 262s / 100cc. After the diaphragm is placed in an oven at 130°C for 30 minutes, the shrinka...

Embodiment 3

[0042] The matrix resin is homopolypropylene F401 produced by Yangzi Petrochemical (melting index: 1.8g / 10min; melting point: 166°C) and 20wt% temperature-sensitive polymer additive EPDM rubber, which is melt-mixed in a twin-screw extruder . The melt is extruded through a slit-shaped die and cooled by a chilled roll to obtain a polypropylene base film. The temperature of the chilled roll is 60° C., and the cooled polypropylene base film is folded flat by a traction roll. The polypropylene base film was first stretched longitudinally along the extrusion direction at a stretching temperature of 90°C and a stretching ratio of 3.0; then transversely stretched at a stretching temperature of 110°C and a stretching ratio of 3.0.

[0043] The lithium battery diaphragm prepared by the method has excellent pore size distribution uniformity, a porosity of 49%, and a Gurley value of 250s / 100cc. After the diaphragm is placed in an oven at 130°C for 30 minutes, the shrinkage rate of the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com