Double stator and double wire coil electromagnetic liquid-cooled retarder

A dual-coil, retarder technology, applied in electric brakes/clutches, electrical components, electromechanical devices, etc., can solve the problems of difficult heat dissipation, reduce the braking torque of the electromagnetic retarder, etc., to reduce the overall quality and improve the system. Dynamic torque, the effect of improving the braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention will be further described below in conjunction with the accompanying drawings.

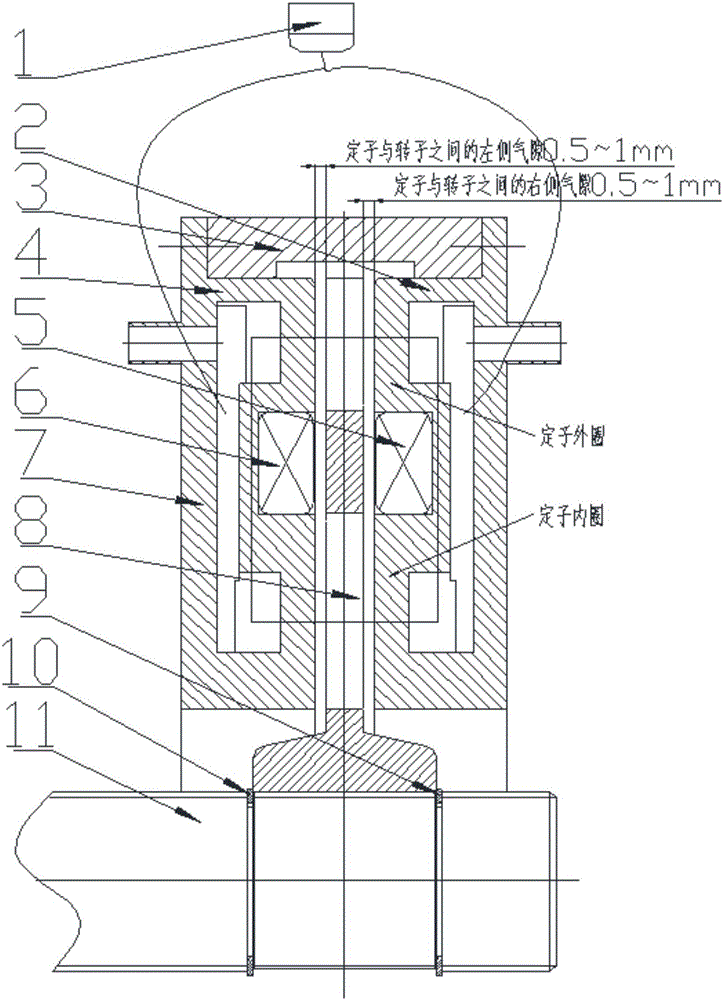

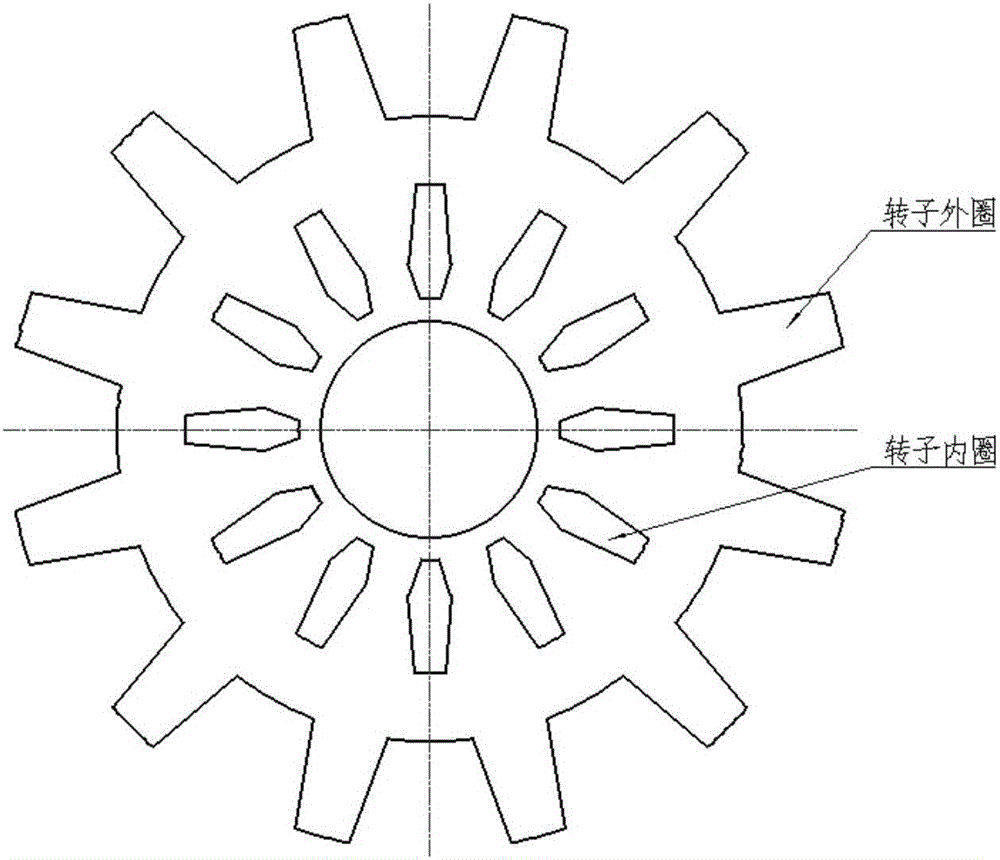

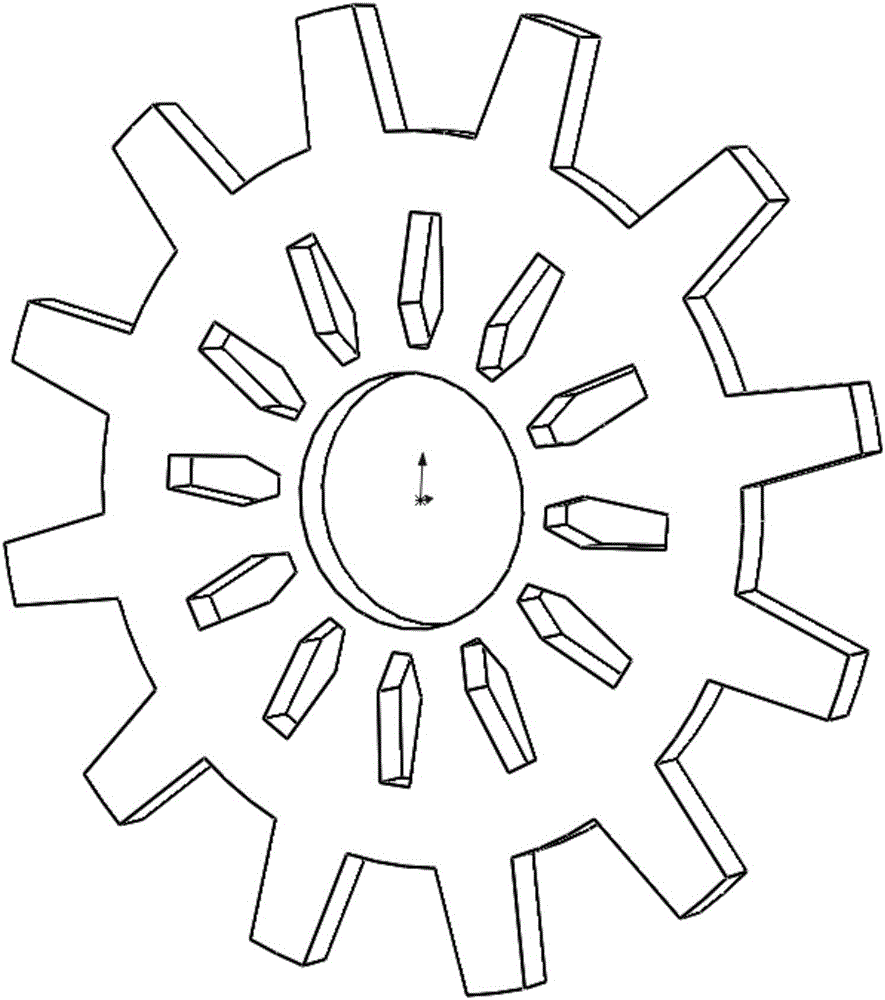

[0027] Such as figure 1 Shown is a schematic diagram of the principle of a double-stator double-coil electromagnetic liquid-cooled retarder. The retarder includes a stator part, a rotor part, an excitation coil group, and a control system 1 . The stator part includes a left stator and a right stator, and an intermediate connector; the excitation coil set includes a left coil 6 and a right coil 5 . The inner and outer rings of the disc rotor are partly dug with tooth-shaped grooves, and when the rotor rotates, an alternating magnetic field is generated on the stator. Its structure is as follows: figure 2 shown. The connector 3 is made of non-magnetic material, and the left stator 4, right stator 2, and rotor 8 are processed from magnetic materials.

[0028] The left stator and the right stator are respectively bolted to the vehicle fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com