A drum brake pad for new energy vehicles with low noise and anti-rust adhesion and preparation method thereof

A new energy vehicle, low-noise technology, applied in the field of vehicle brake pads, can solve problems such as dragging, tires cannot be rotated, cars cannot move, etc., and achieves an increase in the area of the friction film, inhibition of rust, and excellent anti-rust adhesion characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

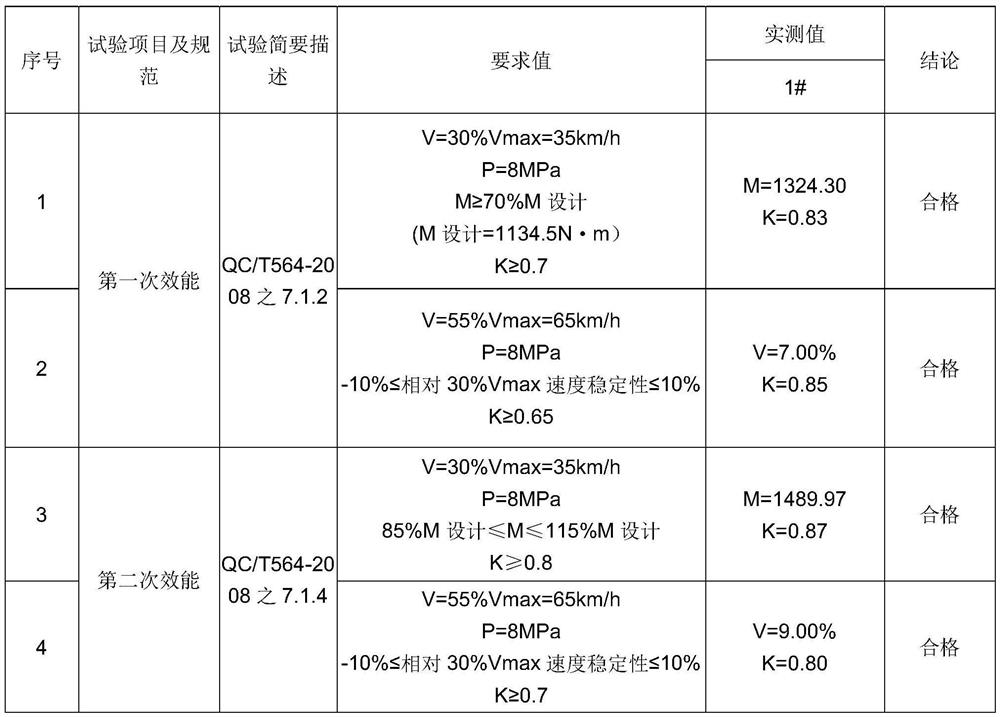

Embodiment 1

[0026] The raw material composition of the low-noise, anti-rust-adhesion brake pad is as follows: mineral fiber 12%, calcium hydroxide 6%, calcium oxide 6%, zinc powder 4%, calcium sulfate whisker 10%, friction powder 3%, high aluminum vanadium Soil 6%, polyacrylonitrile fiber 3%, glass fiber 8%, artificial graphite 6%, resin 11%, rubber 5%, barite balance.

[0027] The preparation process of the non-metallic copper-free new energy vehicle drum brake pad of the present embodiment is:

[0028] (1) Mixing: first premix polyacrylonitrile fiber, mineral fiber and artificial graphite by weight ratio for 5 minutes to ensure that they are in a uniformly dispersed state, then add calcium hydroxide, calcium oxide, and zinc powder in turn by weight ratio, Calcium sulfate whiskers, friction powder, high alumina vanadium, resin, rubber, and barite were stirred at high speed for 5 minutes, and finally added glass fiber, and stirred again at high speed for 2 minutes;

[0029] (2) Hot press...

Embodiment 2

[0043] The raw material composition of the low-noise, anti-rust-adhesion brake pad is as follows: mineral fiber 10%, calcium hydroxide 10%, calcium oxide 5%, zinc powder 5%, calcium sulfate whisker 5%, friction powder 5%, high alumina vanadium Soil 5%, polyacrylonitrile fiber 5%, glass fiber 5%, artificial graphite 15%, resin 10%, rubber 8%, barite balance.

[0044] The preparation method and testing method are the same as those in Example 1.

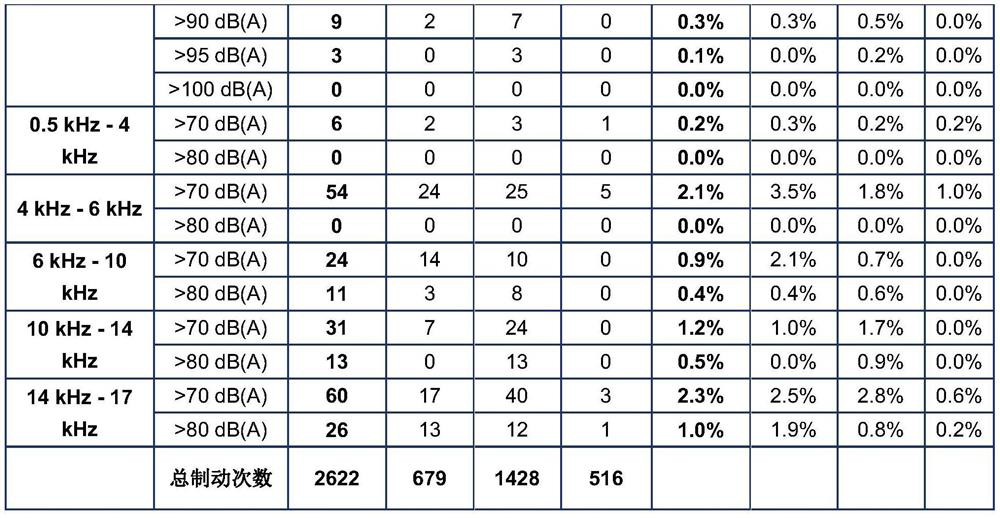

[0045]The test results are as follows: The test results of the adhesion between the shoe and the drum show that the release torque of the brake shoe made according to Example 2 of the present invention is 8.9 N·m, which is lower than the standard requirement. According to the international standard SAE J2521 noise test standard, the brake pads are tested for noise. The results show that the incidence of braking noise of brake pads greater than 70 decibels is 5.6%, and the incidence of braking noise greater than 80 decibels is 1.2%. The...

Embodiment 3

[0047] The raw material composition of the low-noise, anti-rust-adhesion brake pad is as follows: mineral fiber 15%, calcium hydroxide 5%, calcium oxide 10%, zinc powder 3%, calcium sulfate whisker 20%, friction powder 2%, high aluminum vanadium Soil 10%, polyacrylonitrile fiber 2%, glass fiber 10%, artificial graphite 5%, resin 15%, rubber 3%, barite balance.

[0048] The preparation method and testing method are the same as those in Example 1.

[0049] The test results are as follows: The test results of the adhesion between the shoe and the drum show that the release torque of the brake shoe made according to Example 3 of the present invention is 13.1 N·m, which is lower than the standard requirement. According to the international standard SAE J2521 noise test standard, the brake pads are tested for noise. The results show that the incidence of braking noise of brake pads greater than 70 decibels is 7.1%, and the incidence of braking noise greater than 80 decibels is 2.3%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com