Fully-recyclable friction generator and preparation method thereof

A technology of a triboelectric generator and an electrode layer, applied in the direction of triboelectric generators, etc., can solve problems such as environmental pollution, and achieve the effect of simple preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

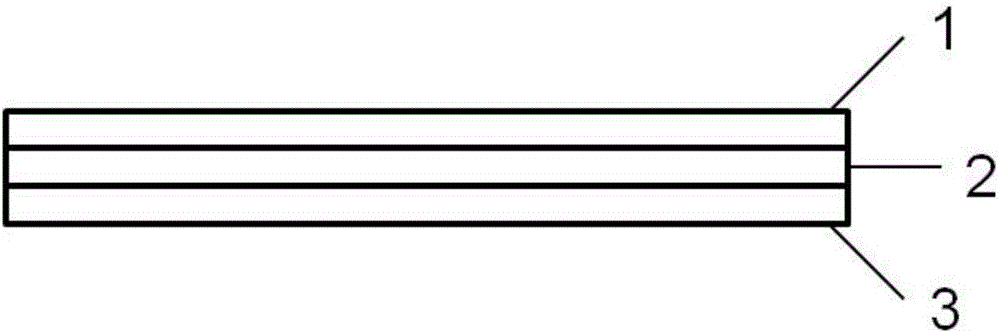

[0032] A preparation method for fully recyclable frictional generators. The preparation method first uses water-soluble organic materials to prepare a functional film layer, forms an electrode layer on one side of the functional film layer by evaporation, and then utilizes the water-soluble organic material to form an electrode layer. The base layer is prepared by using a non-toxic organic material, and then the base layer and the functional film layer coated with the electrode layer are assembled. When assembling, the surface of the functional film that is not coated with the electrode layer is facing outward, and finally the electrode layer is connected to the wire. , to prepare a completely recyclable friction generator.

[0033] The thickness of the functional film layer is 50 microns, the thickness of the base layer is 200 microns, and the thickness of the electrode layer is 200 nanometers.

[0034] Described preparation method specifically comprises the following steps: ...

Embodiment 2

[0053] A preparation method for fully recyclable frictional generators. The preparation method first uses water-soluble organic materials to prepare a functional film layer, forms an electrode layer on one side of the functional film layer by evaporation, and then utilizes the water-soluble organic material to form an electrode layer. The base layer is prepared by using a non-toxic organic material, and then the base layer and the functional film layer coated with the electrode layer are assembled. When assembling, the surface of the functional film that is not coated with the electrode layer is facing outward, and finally the electrode layer is connected to the wire. , to prepare a completely recyclable friction generator.

[0054] The thickness of the functional film layer is 100 microns, the thickness of the base layer is 300 microns, and the thickness of the electrode layer is 300 nanometers.

[0055] Described preparation method specifically comprises the following steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com