Oil well sucker rod carbon fiber heating cable and manufacturing method of the cable

A heating cable and carbon fiber heating technology, which is applied in the direction of insulating cables, heating element materials, heating element shapes, etc., can solve the problems that the insulation wrapping is not moisture-proof and easy to break down, the downhole oil temperature is not reached, and the cable laying is easy to break, etc., to achieve Good moisture-proof insulation effect, long service life and high electrothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

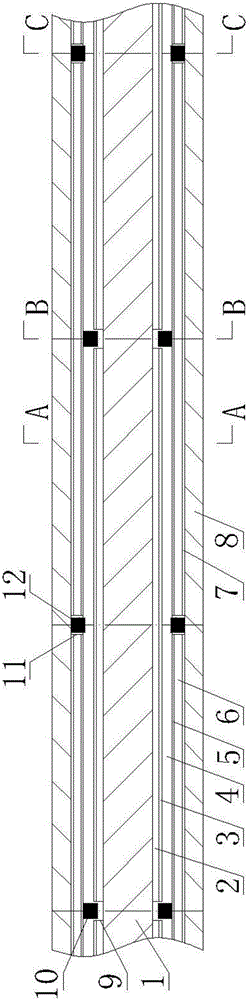

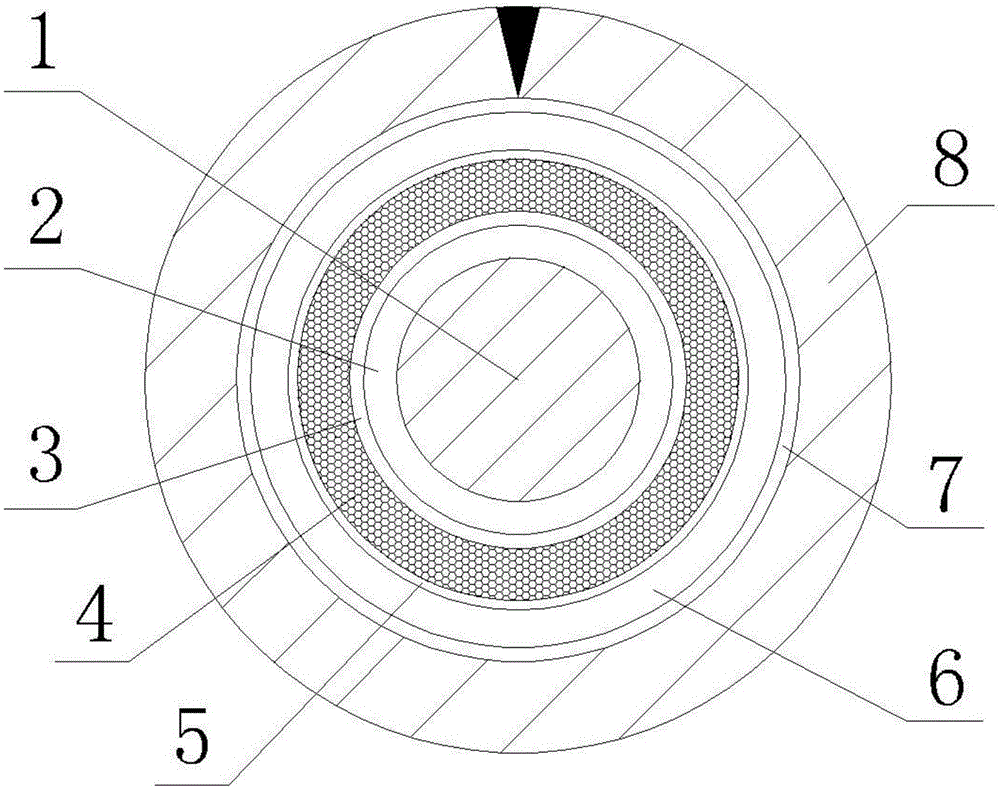

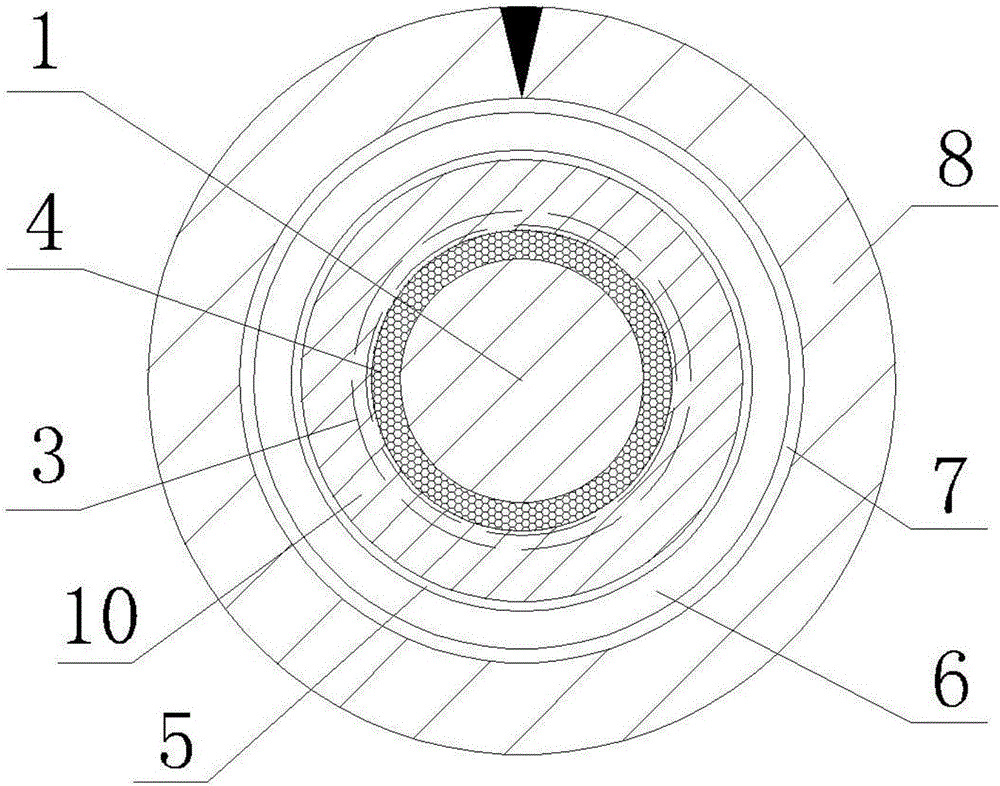

[0047] Such as Figure 1 ~ Figure 4 As shown, the present invention relates to a carbon fiber heating cable for oil well sucker rods, including a copper conductor 1 located in the center, which is formed by extruding an oxygen-free copper rod through an extruder, and the copper conductor 1 The diameter is Φ5.2mm. A conductor insulating layer, a carbon fiber heating layer 4 , a carbon fiber insulating layer and an outer sheath 8 are sequentially provided outside the copper conductor 1 .

[0048] The conductor insulation layer is sequentially composed of a ceramic rubber layer 2 and an insulating inner sheath 3 from the inside to the outside. The carbon fiber insulating layer is composed of a mica tape wrapping layer 5 , a ceramic rubber layer 6 and an insulating outer sheath 7 in sequence from the inside to the outside.

[0049] The ceramic rubber layers 2 and 6 include the following components in parts by weight: 40 kg of silicon rubber, 25 kg of ceramic powder, 15 kg of gla...

Embodiment 2

[0078] Such as Figure 1 ~ Figure 4 As shown, the present invention relates to a carbon fiber heating cable for oil well sucker rods, including a copper conductor 1 located in the center, which is formed by extruding an oxygen-free copper rod through an extruder, and the copper conductor 1 The diameter is Φ5.2mm. A conductor insulating layer, a carbon fiber heating layer 4 , a carbon fiber insulating layer and an outer sheath 8 are sequentially provided outside the copper conductor 1 .

[0079] The conductor insulation layer is sequentially composed of a ceramic rubber layer 2 and an insulating inner sheath 3 from the inside to the outside. The carbon fiber insulating layer is composed of a mica tape wrapping layer 5 , a ceramic rubber layer 6 and an insulating outer sheath 7 in sequence from the inside to the outside.

[0080] The ceramic rubber layers 2 and 6 include the following components in parts by weight: 45 kg of silicone rubber, 20 kg of ceramic powder, 20 kg of gl...

Embodiment 3

[0102] Such as Figure 1 ~ Figure 4 As shown, the present invention relates to a carbon fiber heating cable for oil well sucker rods, including a copper conductor 1 located in the center, which is formed by extruding an oxygen-free copper rod through an extruder, and the copper conductor 1 The diameter is Φ5.2mm. A conductor insulating layer, a carbon fiber heating layer 4 , a carbon fiber insulating layer and an outer sheath 8 are sequentially provided outside the copper conductor 1 .

[0103] The conductor insulation layer is sequentially composed of a ceramic rubber layer 2 and an insulating inner sheath 3 from the inside to the outside. The carbon fiber insulating layer is composed of a mica tape wrapping layer 5 , a ceramic rubber layer 6 and an insulating outer sheath 7 in sequence from the inside to the outside.

[0104] The ceramic rubber layers 2 and 6 include the following components in parts by weight: 42 kg of silicon rubber, 18 kg of ceramic powder, 17 kg of gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com