Equivalent micro-focus target

A focus target and micro focus technology, applied in the field of effective micro focus target, can solve the problems of limited improvement, increase ion beam current, reduce instantaneous temperature rise and average temperature rise, etc., so as to reduce deposition power density and increase ion beam current. The effect of strengthening and increasing the neutron yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

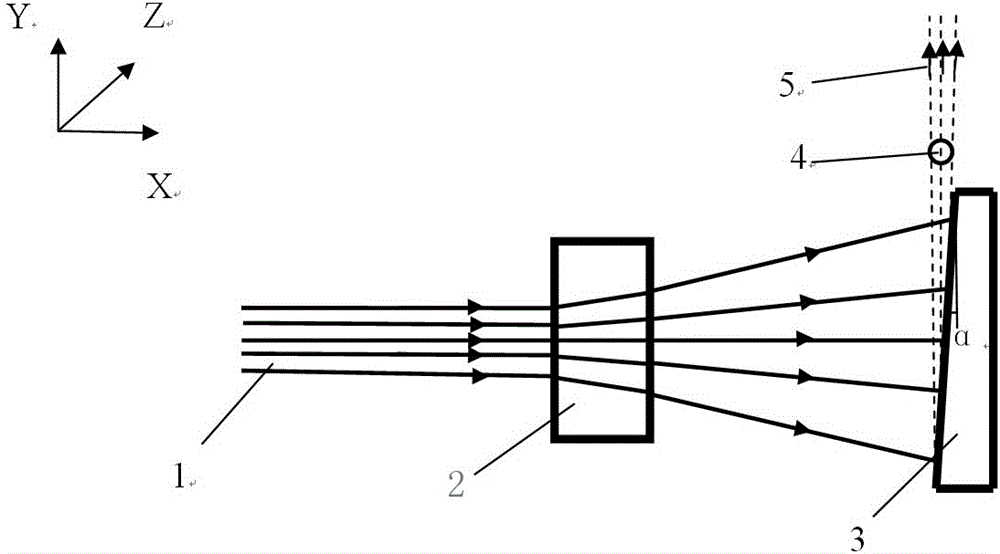

[0025] On the established 250keV, 2mA, 10mm beam spot diameter neutron generator, in order to obtain the effect of 5mm equivalent beam spot, under the condition of constant ion beam current intensity, the peak density of the beam current is increased by 4 times, and the heat dissipation When the conditions are unchanged, the temperature rise will increase by about 4 times, which will far exceed the allowable working temperature of the target. If the temperature rise of the target is kept constant, the ion beam current needs to be reduced by 4 times, and the neutron yield is reduced by 4 times. Using the equivalent micro-focus target of the present invention to transform the original neutron target: first adjust the focusing parameters of the beam optical system, increase the beam spot diameter to 33mm, increase the ion beam current intensity to 2.2mA, and reduce the beam current density by about 10 Then, after passing through the electric quadrupole lens, it becomes a fan-shap...

Embodiment 2

[0027] On the established 250keV, 2mA, 10mm beam spot diameter neutron generator, in order to obtain the effect of 7mm equivalent beam spot, under the condition of constant ion beam current intensity, the peak density of the beam current is increased by 2 times, and the heat dissipation When the conditions remain unchanged, the temperature rise will increase by about 2 times, and the life of the target will be greatly shortened. If the temperature rise of the target is kept constant, the ion beam current needs to be reduced by 2 times, and the neutron yield is reduced by 2 times. Using the equivalent micro-focus target of the present invention to transform the original neutron target: first adjust the focusing parameters of the optical system, increase the beam spot diameter to 33mm, increase the ion beam current intensity to 2.2mA, and reduce the beam current density by about 10 times. After passing through the electric quadrupole lens, it turns into a fan-shaped ion beam, fo...

Embodiment 3

[0029] On the established 250keV, 2mA, 10mm beam spot diameter neutron generator, the ion source was modified to increase the ion beam current intensity by 11 times to 22mA, and the beam spot diameter increased to 33mm. Then adopt the technology of the present invention to transform the original neutron target: after the ion beam passes through the electric quadrupole lens, it becomes a fan-shaped ion beam, forming a bombardment area with a short direction of 10 mm and a length direction of about 110 mm on the target surface, and the bombardment of the moving target 3 The inclination angle α of the surface slope ranges from 3° to 15°, and the moving target 3 translates back and forth ±50mm, the peak density and average density of thermal power deposited on the target surface are reduced by 10 times, the temperature rise of the target surface is reduced by 10 times, and the service life of the target is greatly reduced Extended, the equivalent focal spot remains unchanged at 10m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tilt angle α | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com