Ultrasonic tooth cleaner treatment head and application thereof

A dental scaler and treatment head technology, which is applied in the directions of cleaning teeth, cleaning methods and appliances, dentistry, etc., can solve the problem that the treatment head cannot be used at high frequency, and achieves the advantages of reducing medical costs, improving treatment comfort, and improving heat dissipation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

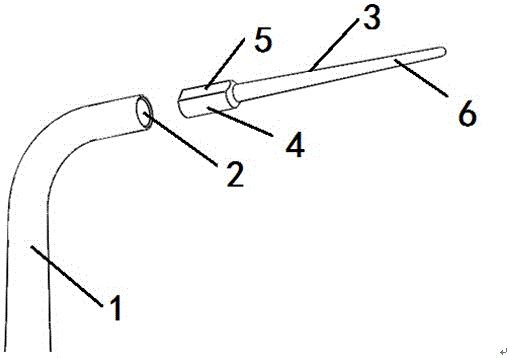

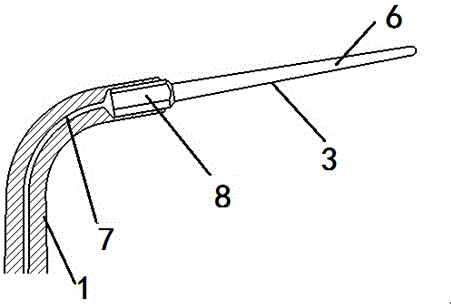

[0025] Such as figure 1 , 2 As shown, a treatment head for an ultrasonic dental scaler includes a base 1 and a working tip 3, the base 1 is provided with a flushing water injection pipeline 7, the working tip 3 is fixed on the base 1, and the fixing point between the working tip 3 and the base 1 is provided There is a flushing water injection hole connected to the flushing water injection pipeline 7, and the lower end of the flushing water injection pipeline 7 is connected with the scaler, and the rinse water of the scaler is introduced. The generated heat damages the working tip. The present invention adopts a unique water-cooling heat dissipation design structure. A flushing water injection hole is provided at the contact surface where the base 1 and the working tip 3 are fixed. The flushing water of the dental machine, the flushing water flows through the contact surface of the carbon fiber or plastic working tip and the metal base and is sprayed out, so that the flushing ...

Embodiment 2

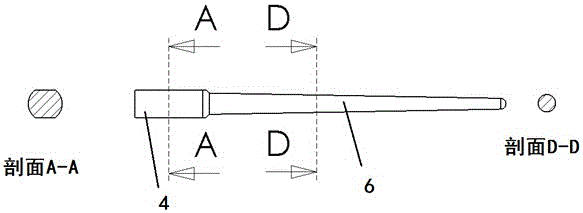

[0028] On the basis of embodiment 1 as preferred, such as Figure 1-4 As shown, the working tip 3 is composed of a root cylinder 4 and an end cylinder 6, the radius of the root cylinder 4 is greater than that of the end cylinder 6, the end cylinder 6 is a tapered columnar structure, and the root cylinder 4 is The columnar structure has flat root flats 5 on both sides of the columnar structure. The base 1 is provided with a working tip installation hole 2 matching the root cylinder 4, the flushing water injection pipe 7 is connected to the working tip installation hole 2, and the root flat 5 of the root cylinder 4 is connected to both sides of the working tip installation hole 2 The wall forms an arched flushing water injection hole, and the diameter of the base cylinder 4 of the carbon fiber or plastic working tip 3 is slightly larger than the diameter of the metal body installation hole. Since the carbon fiber or plastic is soft, the working tip 3 can be pressed into the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com