Automotive front auxiliary frame structure

A front subframe and automobile technology, applied in the substructure, vehicle parts, transportation and packaging, etc., can solve the problems affecting the NVH performance of the whole vehicle, increase the body weight, reduce the quality of the whole vehicle, etc., and improve the fuel economy. , The effect of reducing weight and reducing body weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

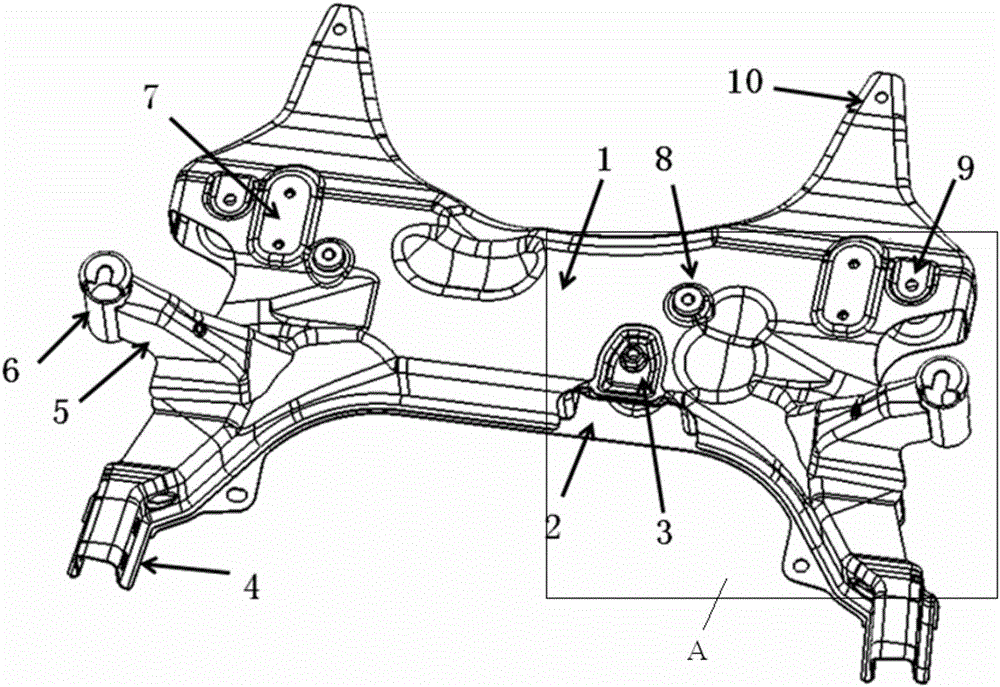

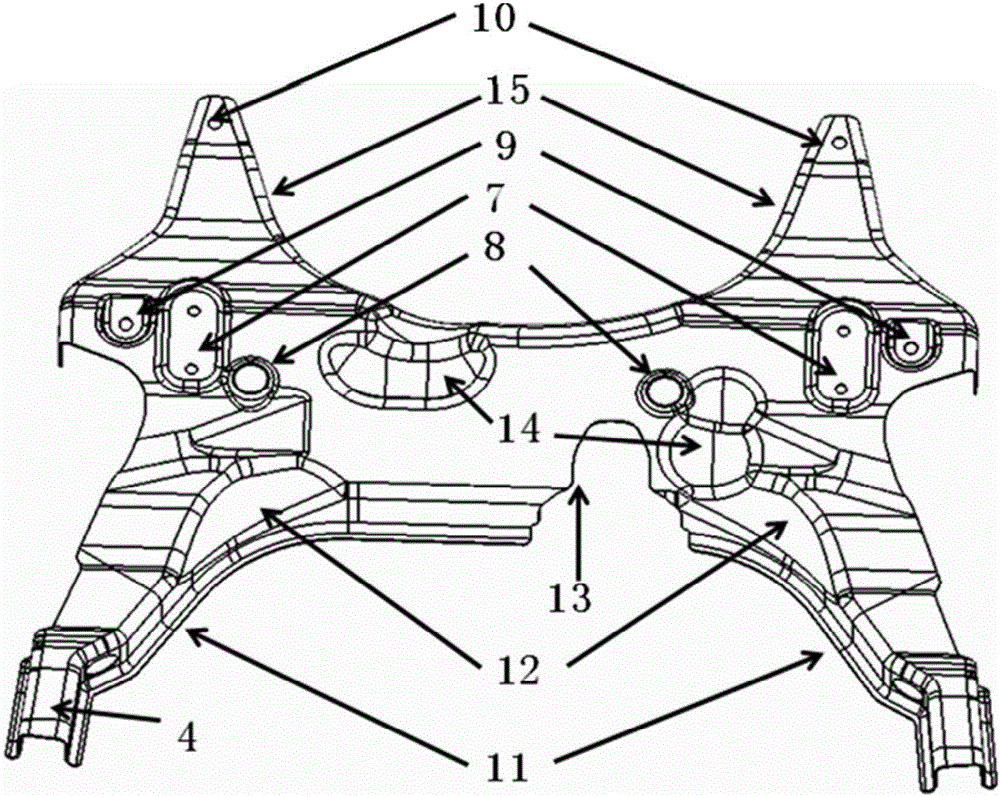

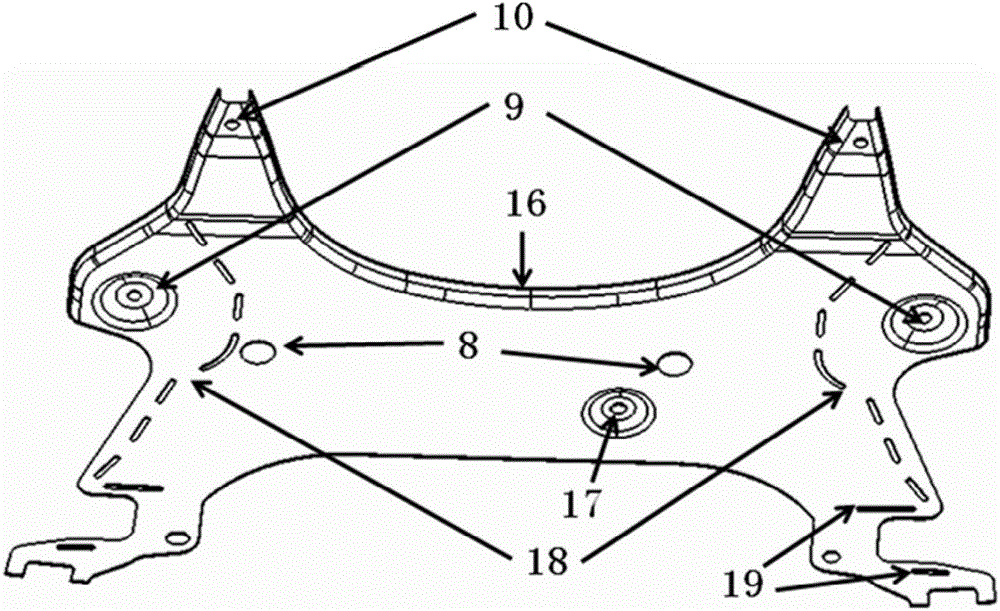

[0027] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

[0028] The present invention aims to solve the problems of complex structure and poor overall rigidity and strength performance of the existing automobile front sub-frame, and its purpose is to

[0029] Overcome the defects existing in the existing technology, thereby providing a safe and reliable working performance, meeting the structural strength and rigidity requirements

[0030] Requirements, and has a higher safety car front sub-frame structure. Its structural design is novel, scientific and reasonable, and its structure is stable

[0031] Good performance, reduce production cost, improve production efficiency; can fully ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com