A kind of preparation method of high-purity lithium oxalate

A technology of pure lithium oxalate and lithium oxalate, which is applied in the field of preparation of high-purity lithium oxalate, can solve the problems of not being able to meet the production requirements of lithium difluorooxalate borate, not suitable for large-scale production, and difficult process control, etc., and achieve low content of impurity elements , cheap raw materials, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

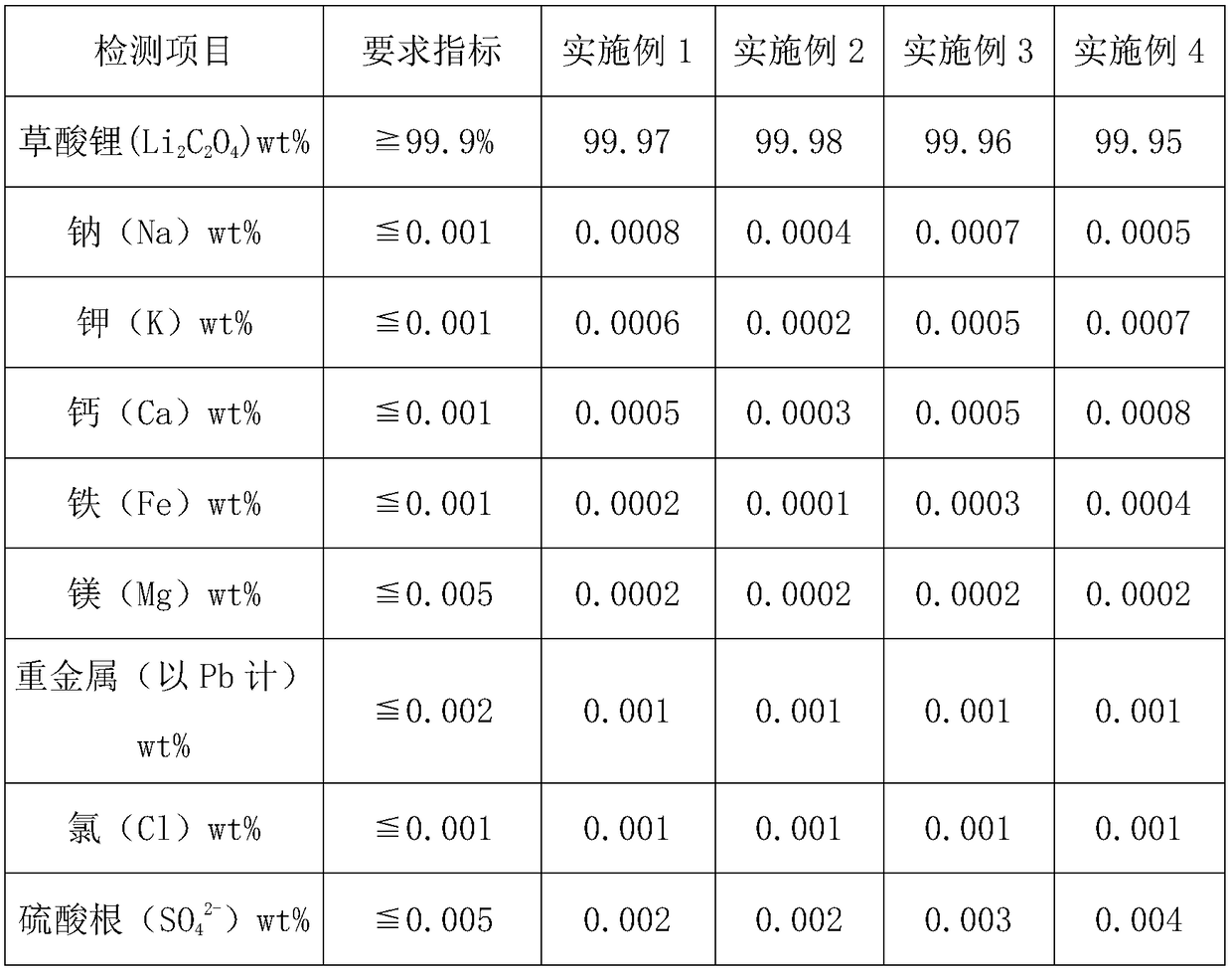

Examples

Embodiment 1

[0016] A preparation method of high-purity lithium oxalate, the steps are as follows:

[0017] (1) Add 300kg of industrial-grade lithium hydroxide monohydrate into 1500L of pure water, dissolve in a plastic container, stir until the solution is clear, and obtain an industrial-grade lithium hydroxide solution. Weigh 450kg of oxalic acid (mass content ≥ 99.9%) with a molar ratio of 1:2 to the lithium element, stir and dissolve in an enamel container with 450L of pure water at a temperature of 90°C to obtain an oxalic acid solution, and slowly add 90kg of the oxalic acid solution into industrial-grade lithium hydroxide In the solution, stir until the reaction is complete, let it stand for 10 minutes, filter and remove impurities until the solution is clear, and obtain a filtered lithium hydroxide solution.

[0018] (2) Take 162kg from the remaining oxalic acid solution in step (1) and add it to the reactor, stir, then slowly add the filtered lithium hydroxide solution obtained in...

Embodiment 2

[0022] A preparation method of high-purity lithium oxalate, the steps are as follows:

[0023] (1) Add 300kg of industrial-grade lithium hydroxide monohydrate into 1500L of pure water, dissolve in a plastic container, stir until the solution is clear, and obtain an industrial-grade lithium hydroxide solution. Weigh 450kg of oxalic acid (mass content ≥ 99.9%) with a molar ratio of 1:2 to lithium, stir and dissolve in an enamel container with 675L of pure water at a temperature of 95°C to obtain an oxalic acid solution, and slowly add 169kg of oxalic acid solution into industrial grade lithium hydroxide solution, stirred until complete reaction, stood still for 20 min, filtered to remove impurities until the solution was clear, and filtered lithium hydroxide solution was obtained.

[0024] (2) Take 239kg from the remaining oxalic acid solution in step (1) and add it to the reactor, stir, then slowly add the filtered lithium hydroxide solution obtained in step (1), until a small ...

Embodiment 3

[0028] A preparation method of high-purity lithium oxalate, the steps are as follows:

[0029] (1) Add 400kg of industrial-grade lithium hydroxide monohydrate into 2000L of pure water, dissolve in a plastic container, stir until the solution is clear, and obtain an industrial-grade lithium hydroxide solution. Weigh 600kg of oxalic acid (mass content ≥ 99.9%) with a molar ratio of 1:2 to lithium, stir and dissolve in an enamel container with 750L of pure water at a temperature of 100°C to obtain an oxalic acid solution, take 135kg of the oxalic acid solution and slowly add industrial grade lithium hydroxide In the solution, stir until the reaction is complete, let it stand for 30 minutes, filter and remove impurities until the solution is clear, and obtain a filtered lithium hydroxide solution.

[0030] (2) Take 364kg from the remaining oxalic acid solution in step (1) and add it to the reactor, stir, then slowly add the filtered lithium hydroxide solution obtained in step (1),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com