Polylactic acid based composite material and preparation method and application thereof

A composite material, polylactic acid technology, applied in the field of polylactic acid-based composite materials and its preparation, can solve the problems of hard and brittle polylactic acid with poor mechanical properties and products that cannot meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

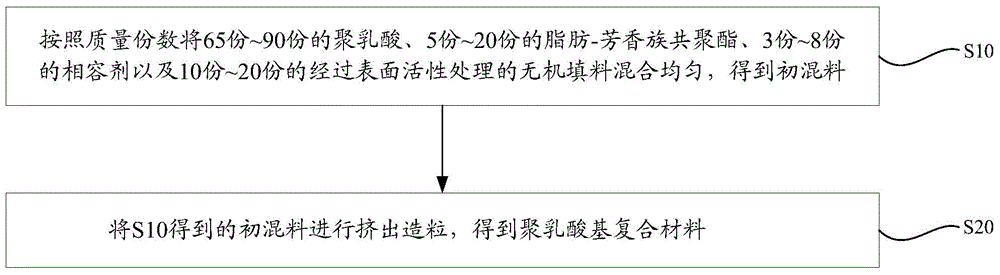

[0034] like figure 1 The preparation method of the above-mentioned polylactic acid-based composite material shown comprises the steps:

[0035] S10, according to the number of parts by mass, 65-90 parts of polylactic acid, 5-20 parts of aliphatic-aromatic copolyester, 3-8 parts of compatibilizer and 10-20 parts of modified inorganic filler Mix evenly to obtain primary mix.

[0036] The operation of mixing evenly can be completed by high-speed stirring equipment. Before mixing the raw materials, it is also necessary to dry the above raw materials. Specifically, the raw materials may be dried in a vacuum oven at 80° C. for 8 hours.

[0037] The polylactic acid has a weight average molecular weight of 100,000-180,000 and a molecular weight distribution index of 1.2-2.

[0038] Preferably, the polylactic acid has a weight average molecular weight of 130,000-170,000 and a molecular weight distribution index of 1.3-1.6.

[0039] The modified inorganic filler is obtained by surfa...

Embodiment 1

[0053] Preparation of inorganic filler surface-treated by coupling agent.

[0054] Titanium dioxide is selected as the inorganic filler, TMC-201 is used as the coupling agent, and the raw materials are weighed according to the weight ratio of titanium dioxide: TMC-201=100:2.5.

[0055] Add the coupling agent into the isopropanol solution, stir at room temperature for 0.5h to obtain an organic solution of the coupling agent; add the inorganic filler into the high-speed stirrer, heat up to 60°C, and spray it into the coupling agent while stirring at a low speed (650rpm). The organic solution of the coupling agent, after adding the organic solution of the coupling agent, continue to stir at high speed (1500rpm) for 15 minutes; finally dry it at 80°C for 4 hours to obtain the inorganic filler surface-treated by the coupling agent.

Embodiment 2

[0057] Preparation of inorganic filler surface-treated by coupling agent.

[0058] Titanium dioxide and zinc white powder were selected as inorganic fillers, TMC-101 was used as a coupling agent, and the raw materials were weighed according to the weight ratio of titanium dioxide: zinc white powder: TMC-101 = 50:50:3.5.

[0059] Using the above-mentioned raw materials, according to the surface treatment process in Example 1, an inorganic filler surface-treated with a coupling agent was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com