Acidic polymer fracturing fluid and preparation method thereof

A technology of acidic polymer and fracturing fluid, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., and can solve the problems of poor fracture-making and sand-carrying ability and fracturing without mentioning organoaluminum-zirconium crosslinking agents. Increased fluid friction and other issues, to achieve good sand-carrying and fracture-making performance, improve fracturing effect, and reduce core damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

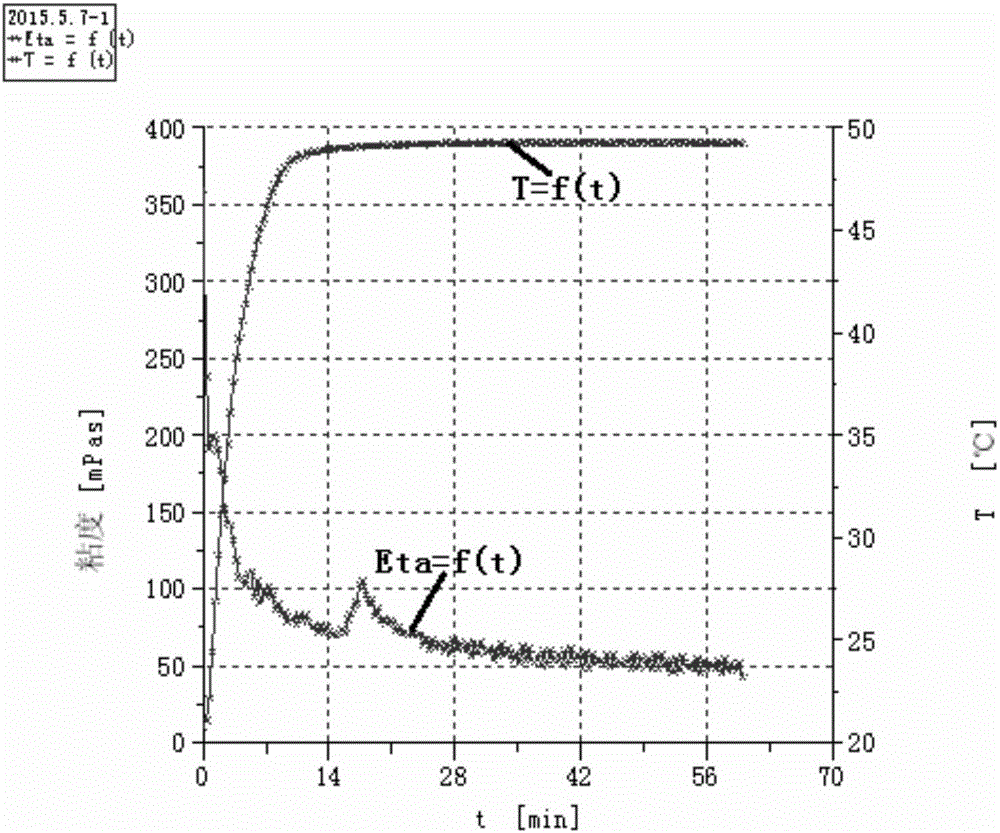

Embodiment 1

[0059] The acidic polymer fracturing fluid of this embodiment includes the following components in mass percentage: 0.25% polymer thickener, 1.0% potassium chloride, 0.2% demulsification aid for fracturing, 0.4% crosslinking agent, Ammonium persulfate 0.05%, surplus are water; Crosslinking agent is the mixture of acid jelly crosslinking agent and organic aluminum zirconium crosslinking agent, and the mass ratio of acid jelly crosslinking agent and organic aluminum zirconium crosslinking agent is 1: 2.

[0060] The preparation method of the present embodiment acidic polymer fracturing fluid comprises the following steps:

[0061] 1) Take the prescribed amount of water, add the prescribed amount of polymer thickener while stirring, and then add the prescribed amount of potassium chloride and demulsification aid for fracturing, stir for 30 minutes, and mix well to get the product Base fluid;

[0062] 2) During fracturing construction, when injecting fracturing fluid, add a cros...

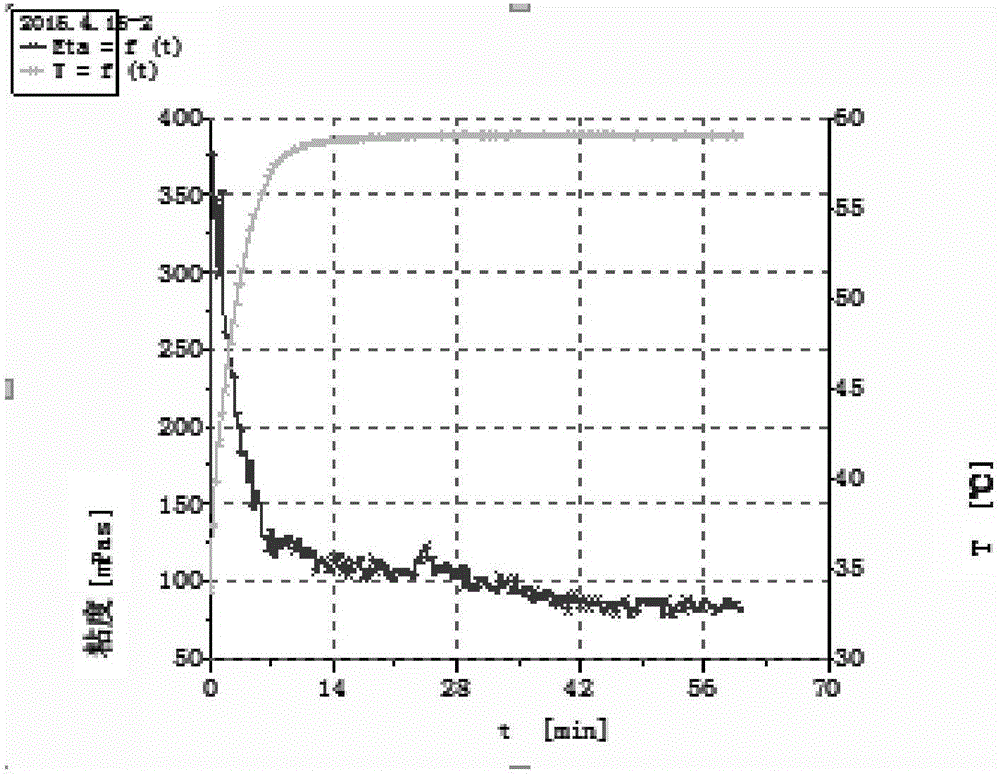

Embodiment 2

[0065] The acidic polymer fracturing fluid of this embodiment includes the following components in mass percentage: 0.3% of polymer thickener, 1.0% of potassium chloride, 0.2% of demulsification and drainage aid for fracturing, 0.4% of crosslinking agent, Ammonium persulfate 0.01%, surplus are water; Crosslinking agent is the mixture of acid jelly crosslinking agent and organic aluminum zirconium crosslinking agent, and the mass ratio of acid jelly crosslinking agent and organic aluminum zirconium crosslinking agent is 1: 2.

[0066] The preparation method of the present embodiment acidic polymer fracturing fluid comprises the following steps:

[0067] 1) Take the prescribed amount of water, add the formulated amount of polymer thickener while stirring, and then add the formulated amount of potassium chloride and demulsification aid for fracturing, stir for 40 minutes, and mix well to get the product Base fluid;

[0068] 2) During fracturing construction, when injecting frac...

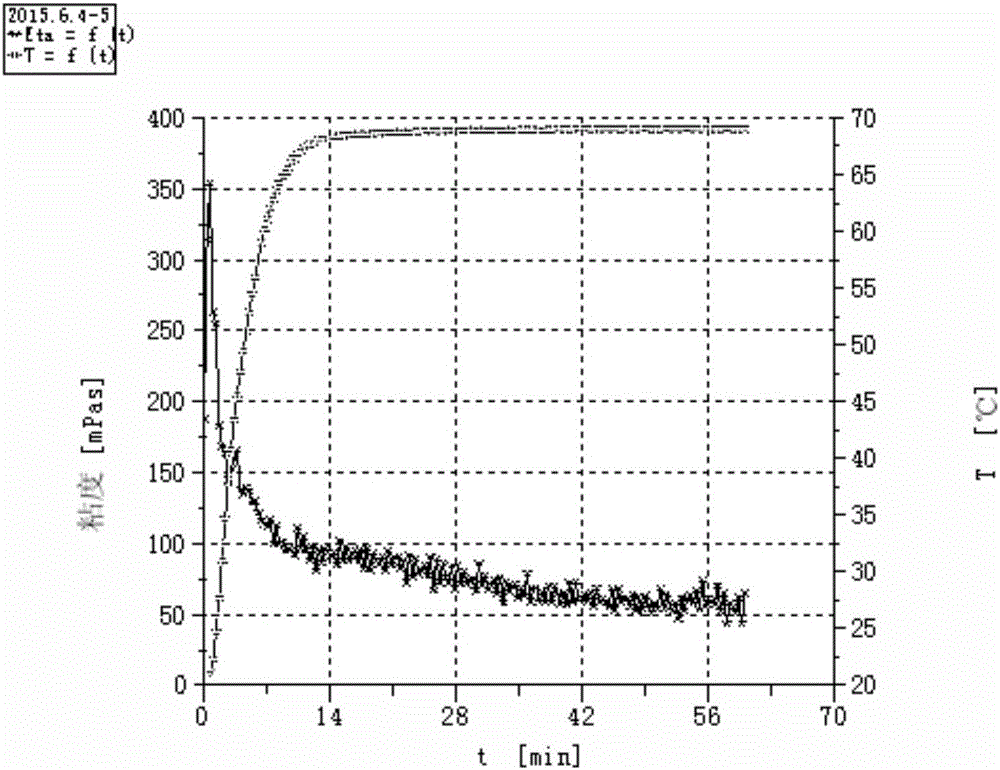

Embodiment 3

[0071] The acidic polymer fracturing fluid of this embodiment includes the following components in mass percentage: 0.3% of polymer thickener, 1.0% of potassium chloride, 0.2% of demulsification and drainage aid for fracturing, 0.5% of crosslinking agent, Ammonium persulfate 0.01%, surplus are water; Crosslinking agent is the mixture of acid jelly crosslinking agent and organic aluminum zirconium crosslinking agent, and the mass ratio of acid jelly crosslinking agent and organic aluminum zirconium crosslinking agent is 1: 2.

[0072] The preparation method of the present embodiment acidic polymer fracturing fluid comprises the following steps:

[0073] 1) Take the prescribed amount of water, add the prescribed amount of polymer thickener while stirring, and then add the prescribed amount of potassium chloride and demulsification aid for fracturing, stir for 50 minutes, and mix well to get the product Base fluid;

[0074] 2) During fracturing construction, when injecting frac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com