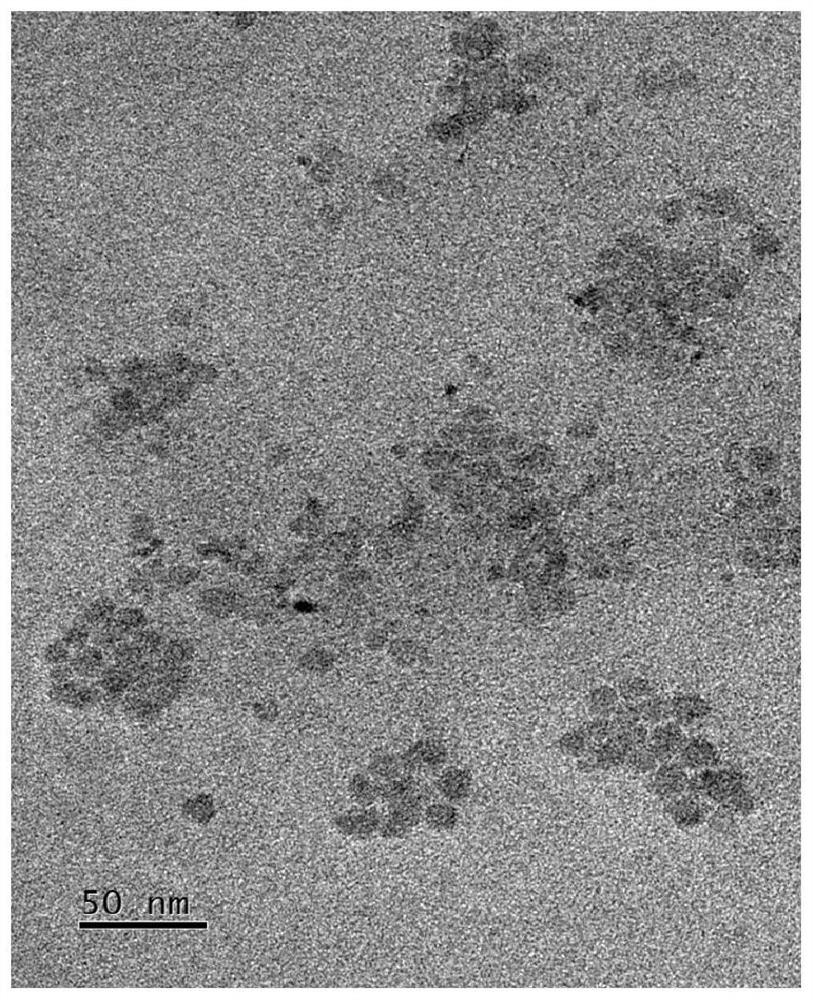

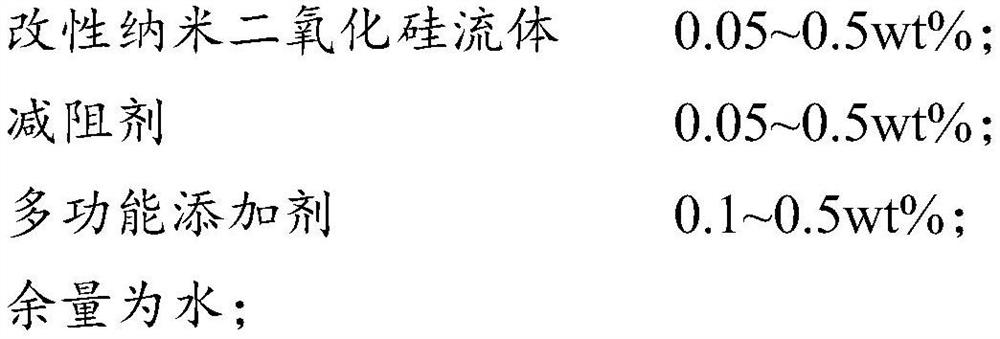

Modified nano silicon dioxide fluid, preparation method and application thereof, slickwater fracturing fluid and application thereof

A nano-silica, silicon dioxide technology, applied in chemical instruments and methods, mining fluids, earth drilling and mining, etc., can solve the problem of low recovery rate of dialysis, and achieve the effect of excellent dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

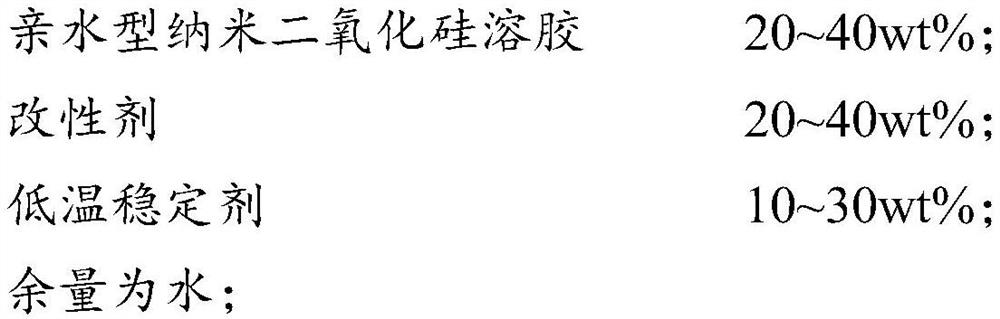

[0038] The present invention also provides a method for preparing the modified nano-silica fluid according to the above scheme, which includes the following steps: mixing and modifying the hydrophilic nano-silica sol, a modifier, a low-temperature stabilizer and water to obtain the modified nano-silica sol. Sexual nano silica fluid;

[0039] The temperature of the modification is 70-90°C.

[0040] In the present invention, the mixing of the hydrophilic nano-silica sol, the modifier, the low-temperature stabilizer and the water preferably includes: heating the water to the modified temperature, adding the low-temperature stabilizer to the water during the heating, and then adding the low-temperature stabilizer to the water. The hydrophilic nano-silica sol is added to the obtained first mixed solution, and then a modifier is added to the obtained second mixed solution.

[0041]In the present invention, the mixing is preferably carried out under stirring conditions. The present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com