A method and system for improving recovery of shale gas wells

A shale gas well and recovery technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of non-compliance with environmental protection requirements, groundwater pollution, low gas production efficiency, etc., and achieve convenient operation, High extraction rate, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: a method for improving the recovery of shale gas wells, comprising the steps of:

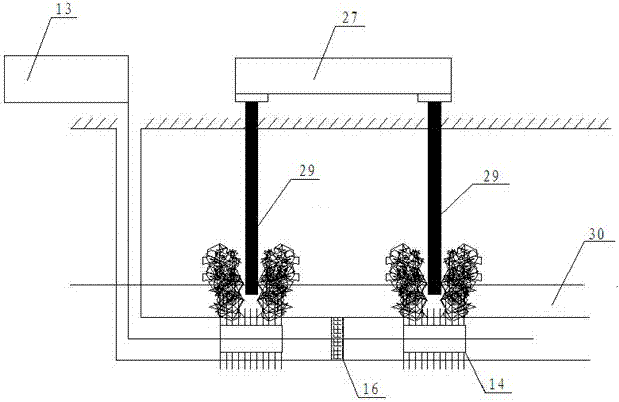

[0042] S1: Pipeline laying, drilling horizontal wells in shale formations, and then arranging pipelines in horizontal wells and vertical shafts formed for drilling horizontal wells;

[0043] S2: put high pressure CO 2 Into the pipeline in the horizontal well in the main pipeline, the high-pressure air detonates, forming a series of high-pressure air pulsating vibrations, breaking through the hollow pipe wall and the horizontal well wall, and forming initial fractures in the shale layer;

[0044] Then, using the principle of hydraulic fracturing, the liquid CO 2 The pipeline is pressed into the initial fracture position of the shale layer, and then the rock at the initial fracture position of the shale layer is heated to make the liquid CO 2 The phase change vaporizes rapidly, generating a series of high-pressure air pulse vibrations to crack the initial fractures in the sh...

Embodiment 2

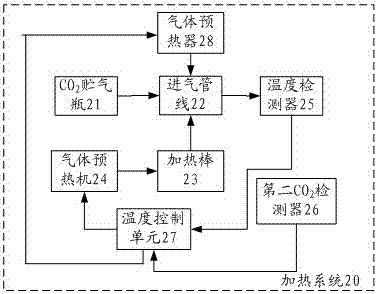

[0052] Embodiment 2: A system for implementing the method for enhancing the recovery of shale gas wells in 1, which includes a fracture-making system and a heating system.

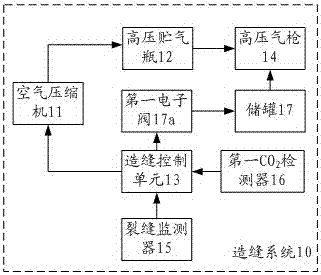

[0053] The seam-making system 10 includes an air compressor 11 located on the ground surface, a high-pressure gas storage bottle 12, a storage liquid high-pressure CO 2 storage tank 17, the first CO 2 The detector 16 and the fracture-making control unit 13 also include a high-pressure air gun 14 and a fracture monitor 15 located under the ground.

[0054] Liquid high pressure CO in storage tank 17 2 outlet with liquid CO 2 Transfer line connected, liquid CO shown 2 The part of the delivery pipeline close to the storage tank 17 is provided with an electronic valve 17a for controlling the output of the storage tank 17 . Storage of liquid high pressure CO 2 The storage tank 17 is provided with a normal pressure protection device and a normal temperature protection device.

[0055] The compressed gas out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com