Keratinase generating pseudomonas aeruginosa and application thereof

A Pseudomonas aeruginosa, keratinase technology, applied in bacteria, microorganism-based methods, microorganisms, etc., can solve problems such as difficult biodegradation, energy and environmental pollution, and difficulty in direct utilization, and achieve high degradation rate and good stability. , the effect of high keratinase activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

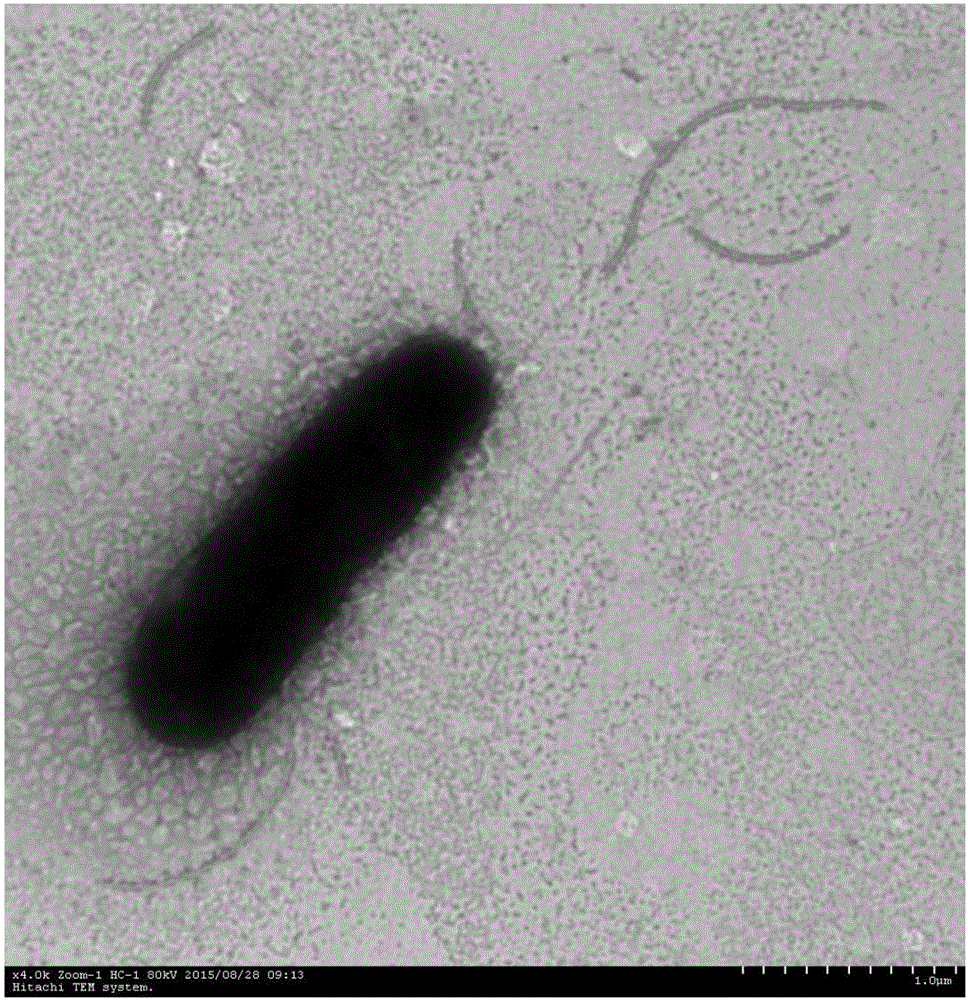

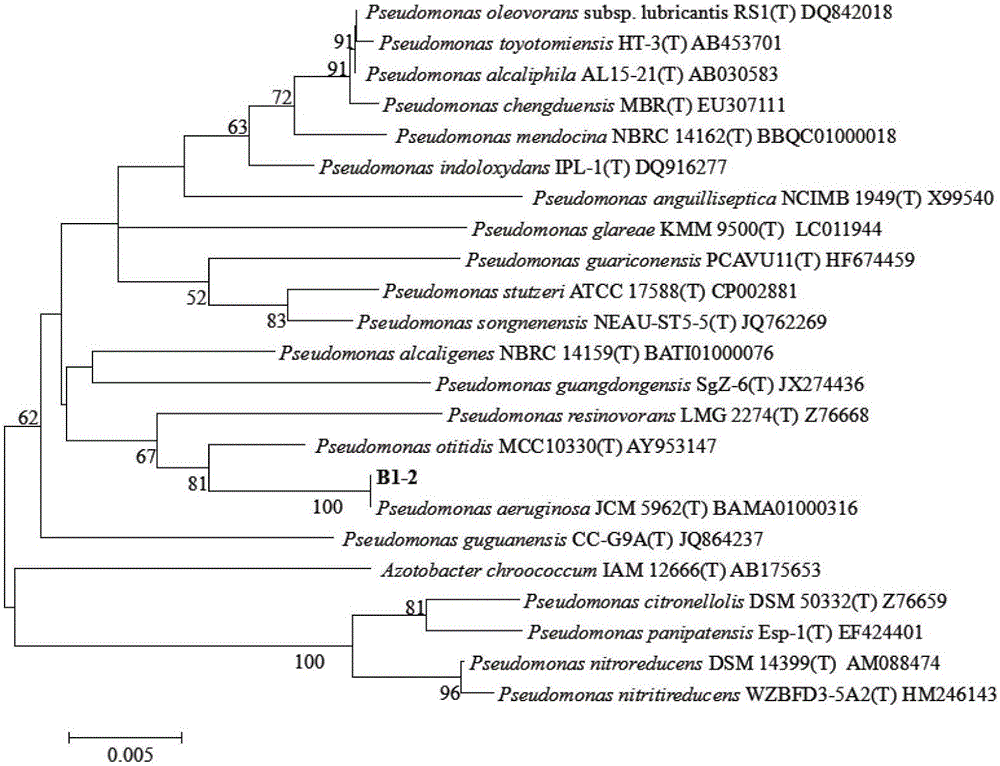

[0047] Embodiment 1 is used to illustrate the screening and identification process of bacterial classification:

[0048] 1. Screening method for strains producing keratinase:

[0049] 1) Soil samples were collected from a chicken farm of Guangdong Wens Food Group Co., Ltd.;

[0050] 2) Mix the collected samples in sterile distilled water, take the supernatant after standing, press 10 -6 、10 -7 、10 -8 After performing gradient dilution, spread on the agar plate medium containing milk; then place it in a 37°C incubator and incubate it upside down for 24 hours;

[0051] 3) Select a single colony that can produce a transparent degradation circle on the agar plate medium, inoculate it in a liquid inorganic salt medium containing feathers, and culture it with shaking at a temperature of 37 ° C and 180 rpm for 72 hours to obtain a culture medium for the strain; finally select The culture solution of strains with obvious feather degradation is inoculated into a new feather-contain...

Embodiment 2

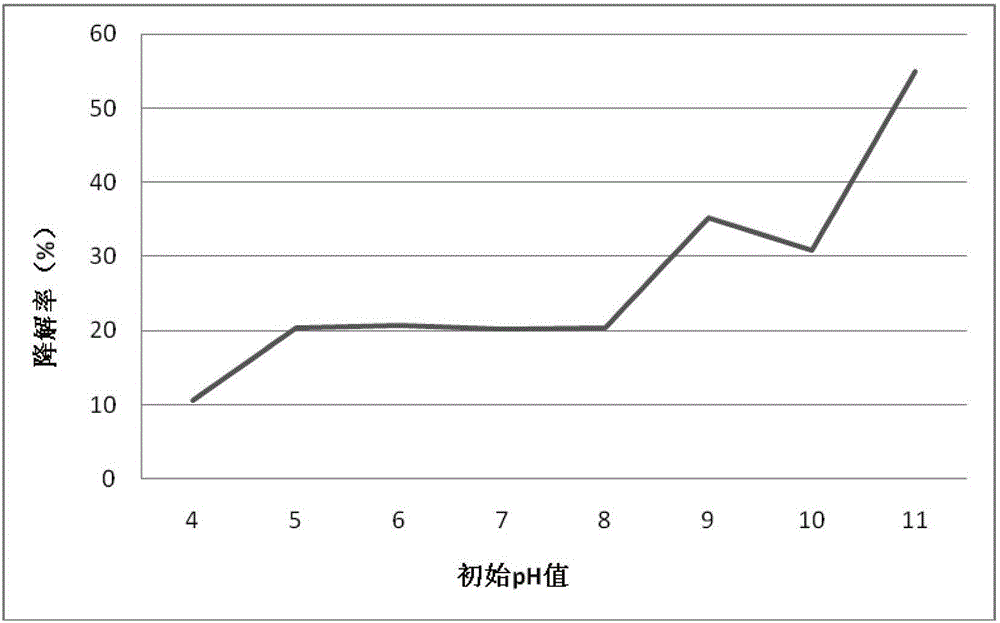

[0077] Example 2 is used to illustrate the degradation conditions of Pseudomonas aeruginosa producing keratinase to keratin:

[0078] 1) Prepare 50 mL of liquid inorganic salt medium with a pH of 4 to 11 according to the gradient;

[0079] 2) Add 0.5 mL of Pseudomonas aeruginosa strains and 0.5 g of feathers to each liquid inorganic salt medium prepared in step 1), and ferment for 24 hours under the conditions of 220 rpm and 37° C., and pass The degradation rate of feathers is detected by weight loss method;

[0080] 3) The degradation rate of different pH to feather is as follows: image 3 Shown: the result shows that when the pH=11 of liquid inorganic salt medium, the degradation rate of feather is the highest;

[0081] 4) Take the strain of Pseudomonas aeruginosa, add it to the liquid inorganic salt medium with pH = 11, and ferment under the temperature conditions of 27°C, 32°C, 37°C, 42°C and 47°C respectively at a rotation speed of 220rpm 24h, then detect the degradati...

Embodiment 3

[0084] Embodiment 3 is used to illustrate the influence of Pseudomonas aeruginosa bacterial age on keratin degradation rate:

[0085] Inject Pseudomonas aeruginosa strains with ages of 4h, 8h, 12h, 16h, 20h and 24h into the liquid inorganic salt medium respectively, the inoculation amount of the strains is 1%, and the feather concentration is 10g / L, pH =11, temperature is 24h under the condition of 37 ℃ of fermentation; The degradation rate of feather is as follows Figure 5 Shown: when the bacterial age is 12h, the degradation rate of feathers is the highest, followed by 16h; before 12h, with the increase of bacterial age, the activity of Pseudomonas aeruginosa strains gradually increases, and the degradation rate of feathers also increases. After 16 hours, the degradation rate of feather decreased rapidly with the increase of bacterial age.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com