Super-soft fiber skin wipe and producing method thereof

A skin cleaning and production method technology, applied in the field of daily hygiene products, can solve the problems of complicated preparation process and single skin care ingredients, and achieve the effect of good effect, better comfort and mild taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

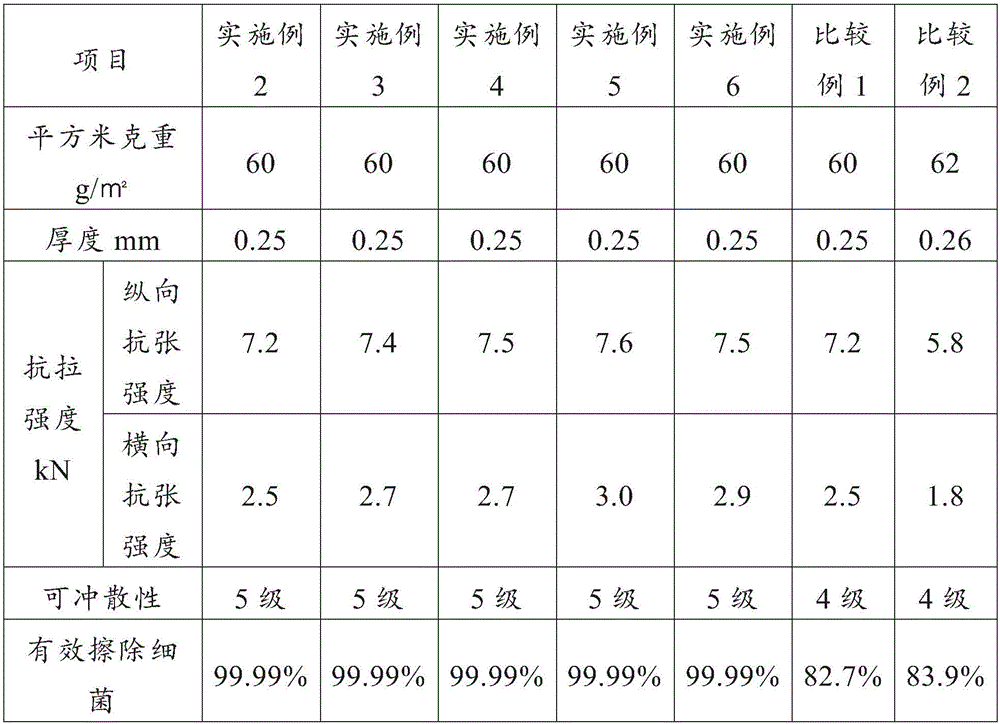

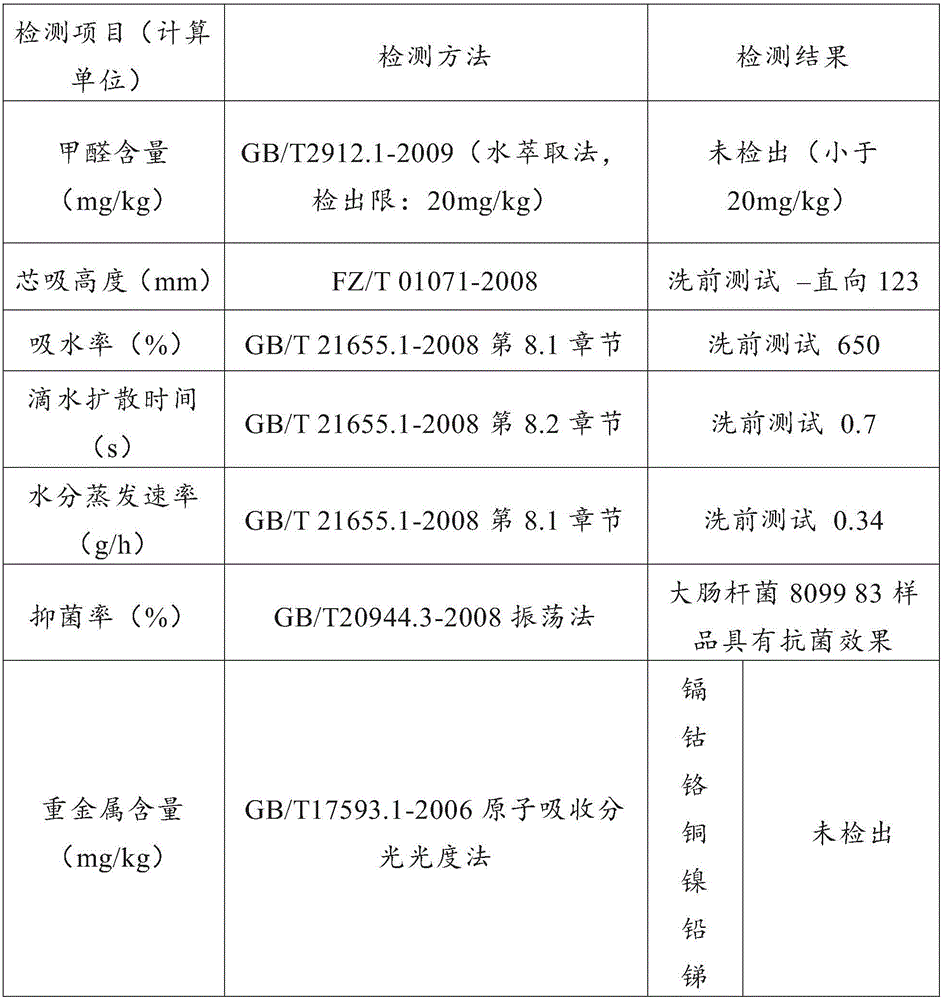

Examples

Embodiment 1

[0017] Embodiment 1: a kind of supersoft fiber skin cleansing towel, comprises the raw material components of following parts by weight: 1 part of lint cotton, 40 parts of cottonseed, 1 part of silk, 10 parts of pearl powder and 0.1 part of shell powder.

Embodiment 2

[0018] Embodiment two: a kind of production method of ultra-soft fiber skin cleansing towel, comprises the following steps:

[0019] Step 1: Pretreatment of lint and cottonseed: dehydrating the lint and cottonseed respectively and removing impurities to obtain pretreated lint and cottonseed;

[0020] Step 2: Prepare super soft fiber: take 1 part by weight of the lint pretreated in Step 1 and 40 parts by weight of the cottonseed after Step 1 pretreatment, mix evenly, place in a drum machine for heating and rotating treatment, To obtain ultra-short fibers, add 1 part by weight of silk to the ultra-short fibers, mix uniformly and extrude and solidify with a spinning pump to obtain ultra-soft fibers; the method of the weaving process is: each adjacent The weft thread woven between two warp threads is C-shaped weaving, and the warp thread woven between every adjacent two weft threads is C-shaped weave;

[0021] Step 3: Prepare ultra-soft fiber skin cleansing towel: take 10 parts b...

Embodiment 3

[0022] Embodiment three: a kind of supersoft fiber skin cleansing towel, comprise the raw material component of following parts by weight: comprise the raw material component of following parts by weight: 10 parts of lint, 30 parts of cottonseed, 10 parts of silk, 8 parts 1 part of pearl powder, 2 parts of shell powder, 1 part of vitamin E, 10 parts of geranium essential oil, 5 parts of rose essential oil and 10 parts of glycerin.

[0023] A production method of supersoft fiber skin cleaning towel, comprising the following steps:

[0024] Step 1: Pretreatment of lint and cottonseed: dehydrating the lint and cottonseed respectively and removing impurities to obtain pretreated lint and cottonseed;

[0025] Step 2: Prepare supersoft fiber: take 10 parts by weight of the lint pretreated in step 1 and 30 parts by weight of cottonseed in step 1 pretreated, mix evenly, place in a drum machine for heating and rotating treatment, To obtain ultra-short fibers, add 10 parts by weight of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com