Microvibration prevention building structure and constructing method thereof

A technology of building structure and construction method, which is applied in the direction of building structure, building components, buildings, etc., can solve the problems of unsatisfactory vibration isolation and strengthen the anti-microvibration effect, so as to improve the anti-microvibration effect and prevent concrete The problem of grout leakage and the effect of ensuring the quality of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in conjunction with the accompanying drawings and embodiments.

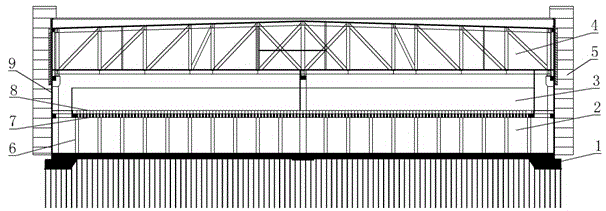

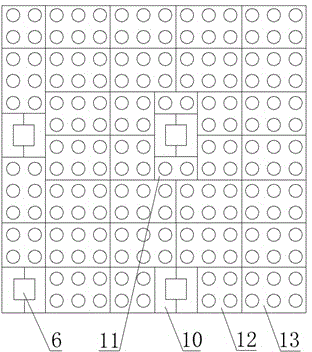

[0035] like figure 1As shown, the anti-microvibration building structure of the present invention includes a base layer 1, a production area and a support area 5, wherein: the production area and the support area 5 are located above the base layer 1; the support area 5 is located on both sides of the production area ; The production area from bottom to top is the return air bottom layer 2, the process production middle layer 3 and the air supply top layer 4; the base layer 1 includes a pile foundation and a raft foundation; the thickness of the raft foundation is 900mm-2500mm , which is provided with double-layer two-way reinforced mesh sheets inside; the air return bottom layer 2 is provided with an encrypted column network 6 for supporting the process to produce the middle layer 3, and the density of the encrypted column network 6 is 4.2m×4.2m The floor of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com