Hydraulic filtering method self-adaptive to working conditions

A hydraulic filtering and self-adaptive technology, which is applied in the direction of fluid pressure actuators, fluid pressure actuator system components, mechanical equipment, etc., can solve the problem that the hydraulic filter has an unsatisfactory attenuation effect on pressure pulsation, and does not solve the problem of pressure pulsation changing with position , The hydraulic filter cannot adapt to the problem of job change, etc., to achieve a good attenuation effect, widen the attenuation frequency bandwidth, and reduce the effect of pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

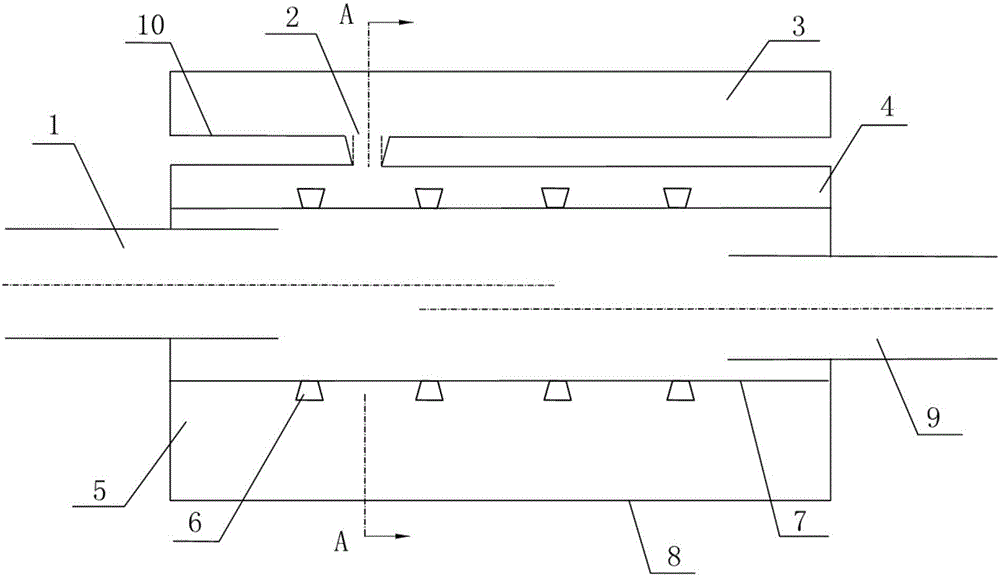

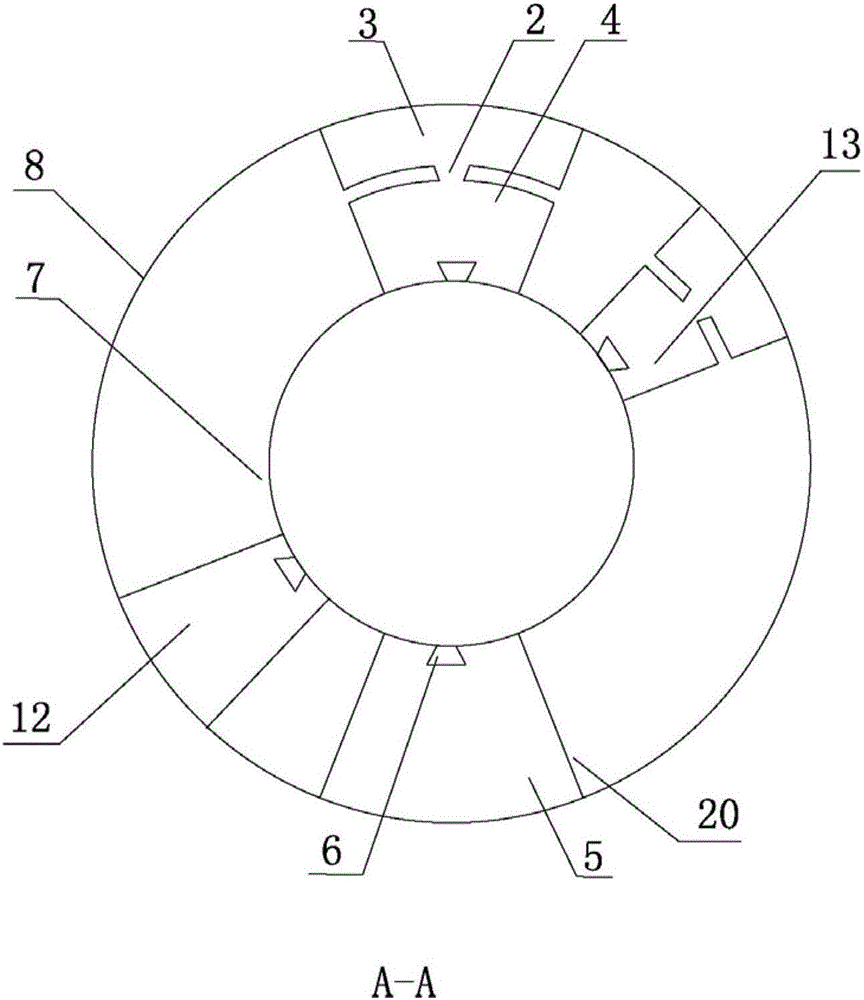

[0033] Please refer to the attached figure 1 to attach Figure 9 As shown, the present invention is a working condition adaptive hydraulic filter, which is composed of input pipe 1, housing 8, output pipe 9, elastic thin wall 7, H-type filter 12, and series H-type filter 13. .

[0034] Wherein, the input tube 1 is connected to one end of the shell 8 and extends into the shell 8 ; the output tube 9 is connected to the other end of the shell 8 and extends into the shell 8 . The elastic thin wall 7 is installed inside the casing 8 along the radial direction of the casing, and an expansion cavity 71 and a contraction cavity 72 are formed therein. The axes of the input pipe 1 and the output pipe 9 are not on the same axis, which can improve the filtering effect by more than 10%.

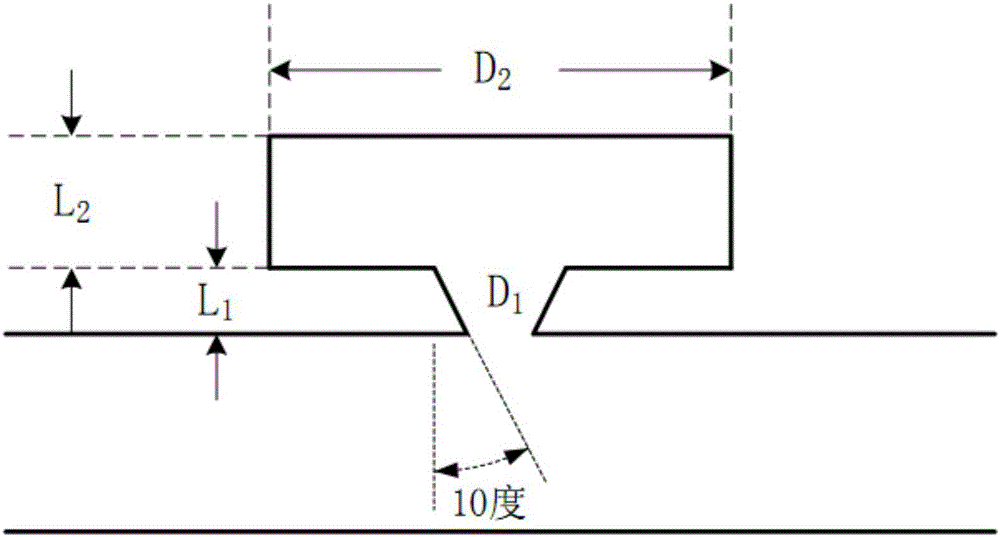

[0035] The input pipe 1, the output pipe 9 and the elastic thin wall 7 jointly form a double-pipe plug-in filter, thereby attenuating high-frequency pressure pulsation of the hydraulic system. The fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com