A double-layer pulsating heat-conducting plate belt and its process

A heat-conducting plate and pulsating heat-pipe technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problem that the heat-conducting effect cannot catch up with the single-metal structure radiator, and the heat pipe is difficult to exert the maximum efficiency, and achieves low cost and mechanization. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

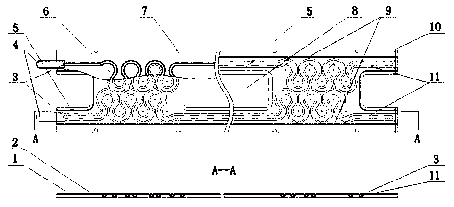

[0015] combined with figure 1 Structure of the present invention and technique are illustrated:

[0016] The invention described as figure 1 As shown in the figure, a double-layer pulsating heat conduction plate strip is mainly composed of a capillary pulsation heat pipe (3) as the main heat conduction device, and a flat heat conduction plate (1) strip formed by punching and forming a stainless steel plate with a window in the middle interval. , and the grooved heat conduction plate (2) of the same size stamped into a groove according to the mold, the capillary pulsation heat pipe is embedded in the groove, and the flat heat conduction plate (1) and the groove heat conduction plate (2) are docked by the positioning plane of the positioning fixing hole , use a special electric spark rolling welding machine to continuously weld the two plates into a figure 1 As shown, the window (8) along the inner space of the heat conduction plate strip is opened with the inner rolling weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com