Determination method of formaldehyde content in waterborne coating adhesive

A technology of formaldehyde content and water-based coatings, which is applied in the direction of analyzing materials through chemical reactions and material analysis through observation of the impact on chemical indicators, and can solve problems such as difficult control of distillation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

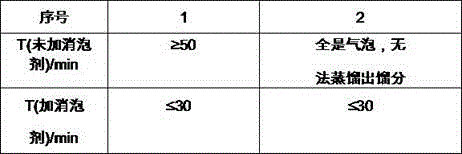

[0091] The mensuration of the formaldehyde content in the water-based paint binder of the present embodiment comprises step 1), the calibration of formaldehyde standard stock solution; Step 2), the preparation of formaldehyde standard solution and step 3), the drawing of standard curve; It is characterized in that Including step 4), the determination of formaldehyde content, the step 4) includes a distillation step, adding a defoamer in the distillation step.

[0092] Step 1) specifically includes the following operations:

[0093] a) Pipette 20.00mL formaldehyde standard stock solution into a 250ml iodine bottle, add 0.05mol / L iodine solution, 25.0mL, immediately add 1 mol / L sodium hydroxide solution drop by drop until the color fades to light yellow After standing for 15 minutes, add 11 mL of 1mol / L hydrochloric acid solution to acidify;

[0094] b) Titrate with the calibrated sodium thiosulfate solution until light yellow, add 1mL of the newly prepared 1g / 100mL starch indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com