Molecular distillation device

A technology of molecular distillation and equipment, which is applied in the field of molecular distillation equipment, can solve the problems of short time, generally only ten seconds to a few minutes, complicated manufacturing and maintenance, and high manufacturing requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

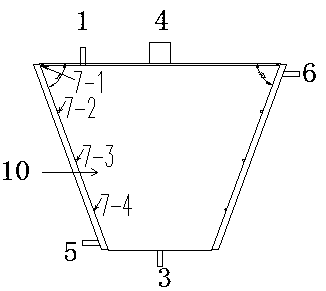

[0037] It includes a molecular distillation equipment body 10 and a vacuum tube 4. The molecular distillation equipment body 10 is an inverted body ring-shaped round platform with an upper ring larger than the lower ring: the two busbars opposite to the inverted body ring-shaped round table are formed by the intersection of the upper bottom The angle is from 10 degrees to 89 degrees; the inner surface of the round platform is the heating surface of the distillation material, and there are several material distributors on the heating surface.

[0038] (1) The two ends of the molecular distillation equipment body 10 are connected to the end caps at both ends, and the top end cap is connected to the material inlet pipe 1. There are multiple material distributors on the heating surface, and the material distributors are processed by steel pipes. circle, the top first material distributor 7-1 has several small holes drilled at the bottom, other material distributors do not need to d...

Embodiment 2

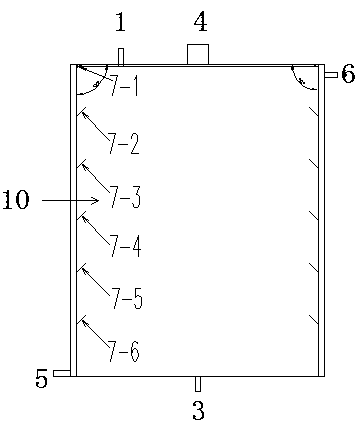

[0045] It includes a molecular distillation equipment body 10 and a vacuum tube 4. The molecular distillation equipment body 10 is an inverted body ring-shaped round platform with an upper ring larger than the lower ring: the two busbars opposite to the inverted body ring-shaped round table are formed by the intersection of the upper bottom The angle is a 90-degree cylinder shape, which is the preferred angle. The cylinder is more convenient to cut and manufacture, and it saves more steel than the circular table shape, and does not cause more waste. The installation takes up less space than the circular table; the cylinder The inner side of the distiller is the heating surface of the distillation material, and there are several material distributors on the heating surface.

[0046] (1) The two ends of the molecular distillation equipment body 10 are connected to the end caps at both ends, and the top end cap is connected to the material inlet pipe 1. There are multiple material...

Embodiment 3

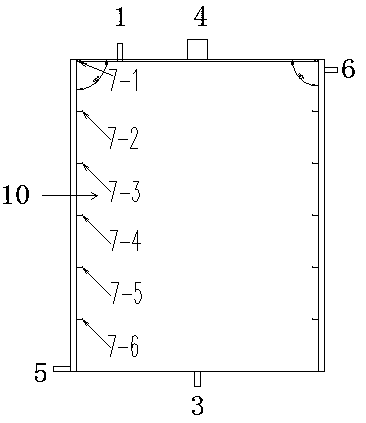

[0052] It includes a molecular distillation equipment body 10 and a vacuum tube 4. The molecular distillation equipment body 10 is an inverted body ring-shaped round platform with an upper ring larger than the lower ring: the two busbars opposite to the inverted body ring-shaped round table are formed by the intersection of the upper bottom The angle is from 10 degrees to 89 degrees; the inner surface of the round platform is the heating surface of the distillation material, and there are several material distributors on the heating surface.

[0053] (1) The two ends of the molecular distillation equipment body 10 are connected to the end caps at both ends, and the top end cap is connected to the material inlet pipe 1. There are multiple material distributors on the heating surface, and the material distributors are processed by steel pipes. circle, the top first material distributor 7-1 has several small holes drilled at the bottom, other material distributors do not need to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com