An alkaline dry battery electrolyte rotary injection device

An injection device and electrolyte technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of short contact time between electrolyte and air, insufficient electrolyte absorption, etc. To achieve the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

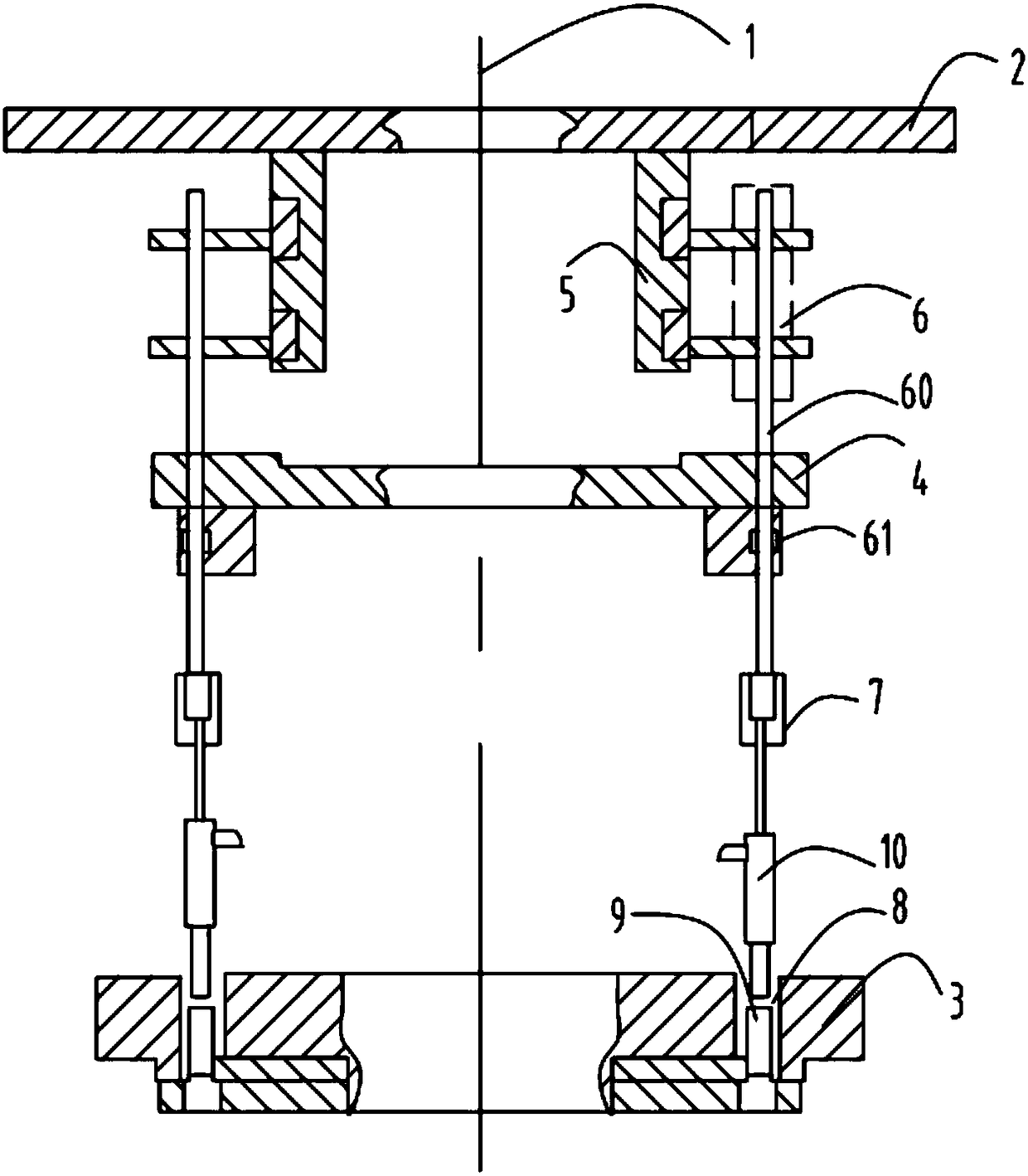

[0031] Such as figure 1 As shown, an alkaline dry battery electrolyte rotary injection device includes a first workbench 2, a second workbench 3 and an intermediate turntable (4) that rotate synchronously with the main machine main shaft 1, and a cam installed on the lower side of the upper bottom plate 5 of the main machine 6. The transmission rod 60 of the cam 6 passes through the intermediate turntable 4, and is arranged on the intermediate connecting sleeve 7 below the intermediate turntable 4. One end of the transmission rod 60 is connected to the cam 6, and the other end is arranged on the middle turntable 4. In the middle connection sleeve 7; the cup holder 8 installed on the second workbench 3 and rotates synchronously with the main machine and the intermediate turntable 4, the cup holder 8 is provided with a battery 9 and also includes an injection mechanism 10.

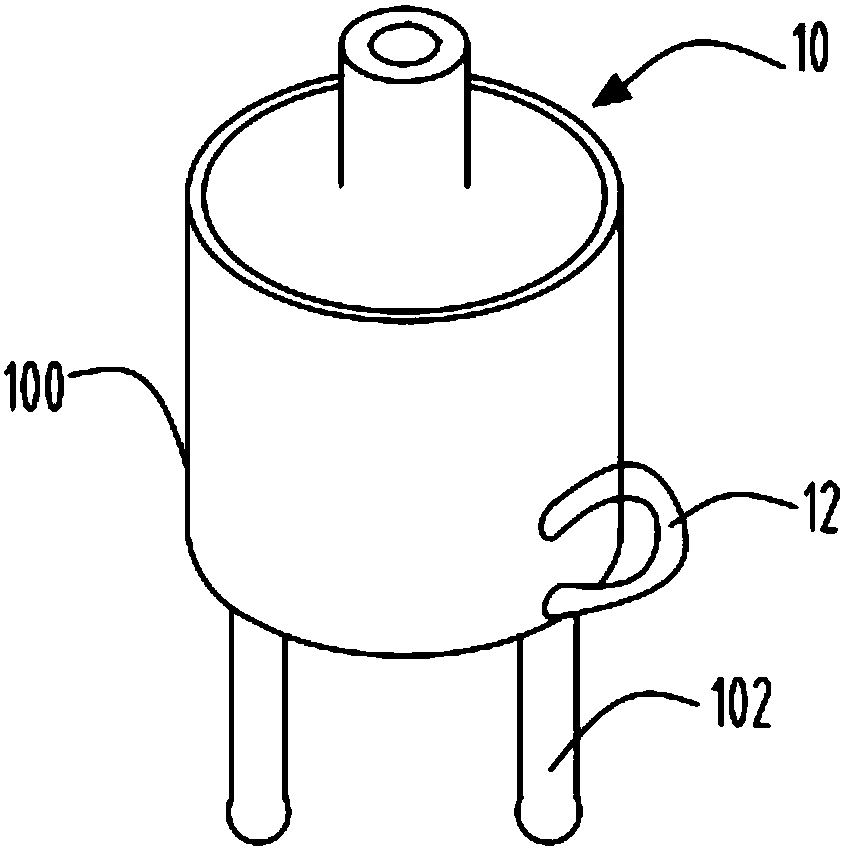

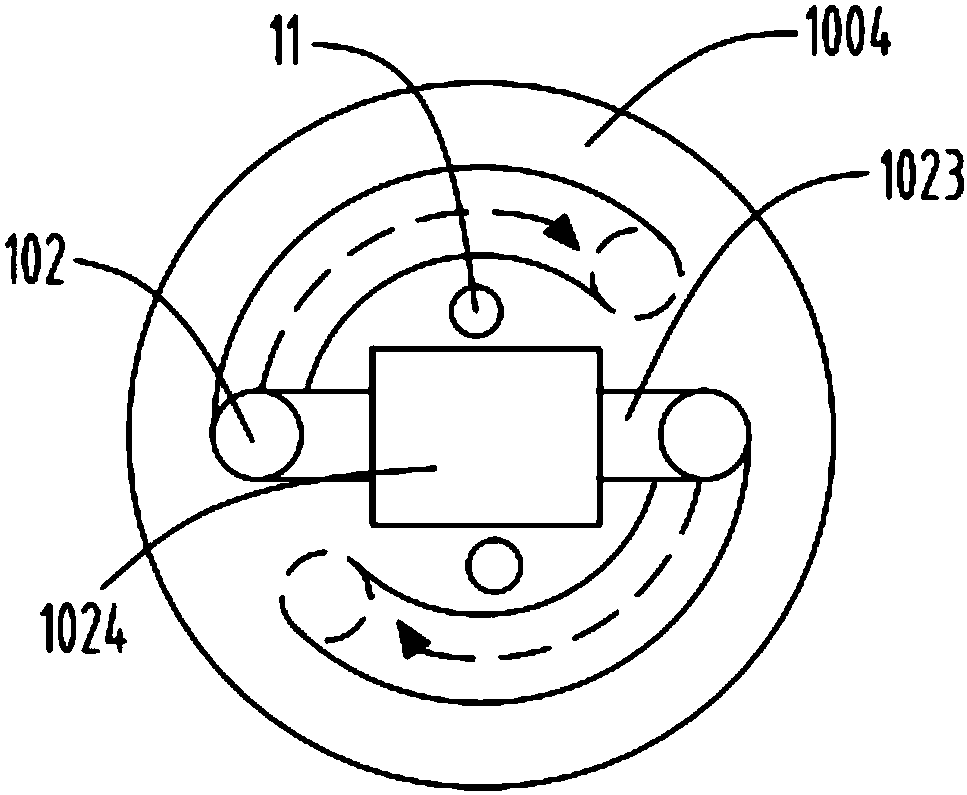

[0032] Such as figure 1 , figure 2 , image 3 and Figure 4As shown, the injection mechanism 10 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com