Direct feature control-based novel salient-pole permanent magnet synchronous motor control method

A permanent magnet synchronous motor, feature control technology, applied in the control of generators, motor generator control, control of electromechanical brakes, etc., can solve problems such as difficult parameter adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further explained below with reference to the drawings and examples.

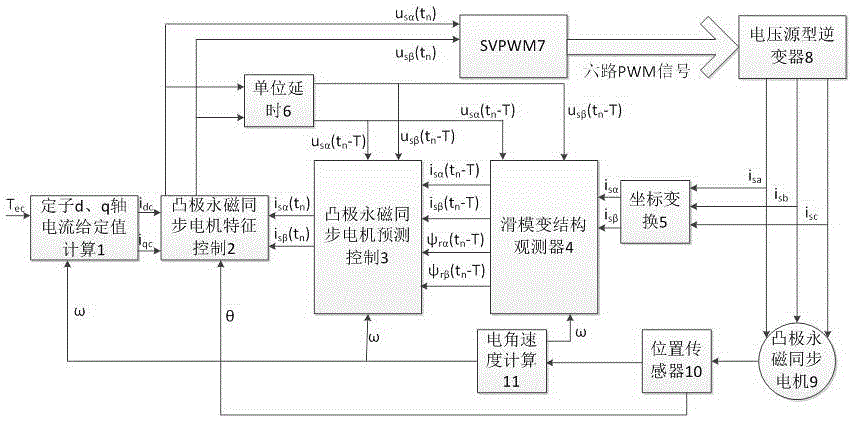

[0061] figure 1 It is a block diagram of the overall structure of a salient pole permanent magnet synchronous motor electric vehicle system based on feature control. The system includes the calculation of stator d and q axis current setpoints 1, the salient pole permanent magnet synchronous motor feature control 2, and the salient pole permanent magnet synchronous motor prediction Control 3. Sliding mode variable structure observer 4. Coordinate transformation 5. Unit delay module 6. SVPWM module 7. Voltage source inverter 8. Salient pole permanent magnet synchronous motor 9. Position sensor 10. Electrical angular velocity calculation module 11. .

[0062] The input terminal of the position sensor 10 is drawn from the output terminal of the salient-pole permanent magnet synchronous motor 9, and the input terminal of the electrical angular velocity calculation module 11 is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com