A straw chopping and throwing test bench

A test bench and straw technology, applied to cutting equipment, agricultural machinery and tools, and packaging, can solve the problems of not being able to quickly and effectively complete the bundling operation, reduce the throwing accuracy of the bundling device, and affect the speed of bundling operations, etc. Achieve the effects of improving the throwing accuracy and bundling efficiency, reducing straw leakage and outside throwing, and good control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

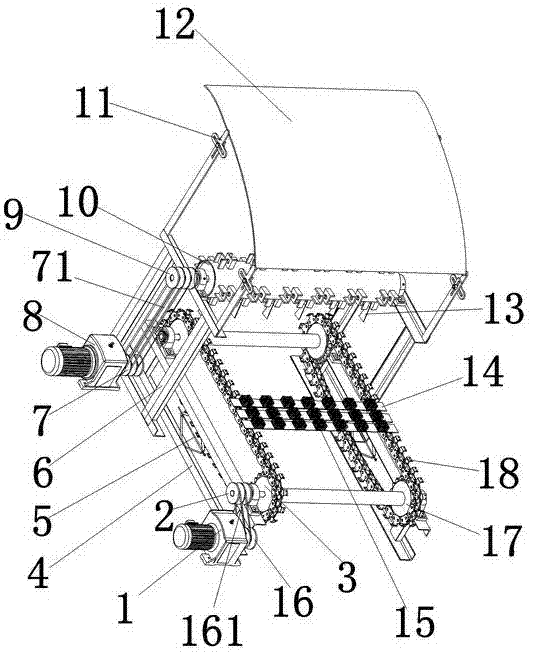

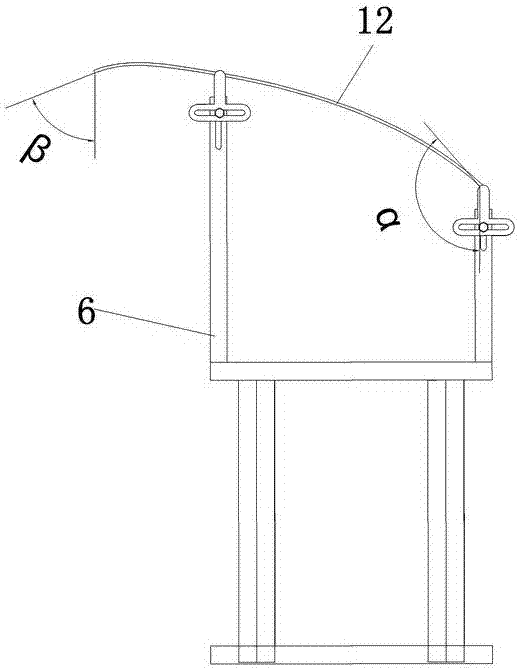

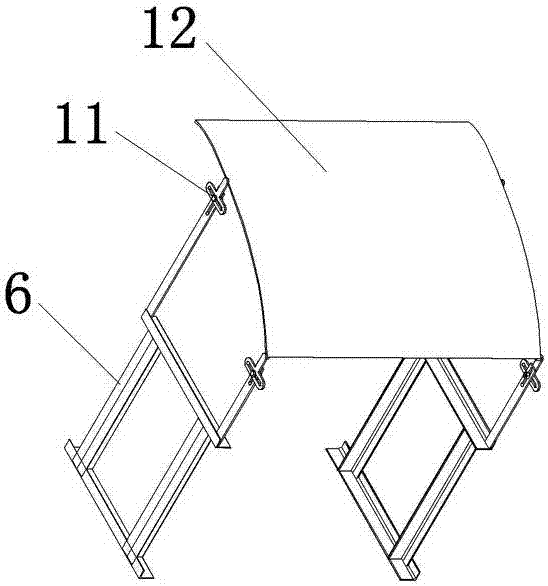

[0034] Such as figure 1 As shown, the present invention includes a first motor 1, a first pulley 2, a conveyor belt 3, a conveyor belt bracket 4, a lifting device 5, a roller bracket 6, a second pulley 7, a second motor 8, a third belt Wheel 9, idler roller 10, T-shaped connector 11, material baffle plate 12, blade 13, chain plate 14, support brush 15 and fourth pulley 16, the first motor 1 passes through the fourth pulley 16 and the first belt 161 is connected with the first pulley 2, the first pulley 2 is installed on the bearing 19 of the conveyor belt 3, and the first motor 1 provides conveying power for the conveyor belt 3;

[0035] Such as Figure 6 As shown, the conveyor belt 3 is composed of a sprocket 17, a chain 18, a bearing 19 and a bearing seat 20; the sprocket 17 is arranged on the bearing seat 20 through the bearing 19, the bearing seat 20 is arranged on the conveyor belt bracket 4, and the chain 18 is wound around On the sprocket 17, chain plates 14 are set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com