Washing system for removing lead in polluted soil

A contaminated soil and leaching technology, which is applied in the field of soil pollution remediation, can solve problems such as limited research, and achieve the effects of easy preparation, low cost, and improved leaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

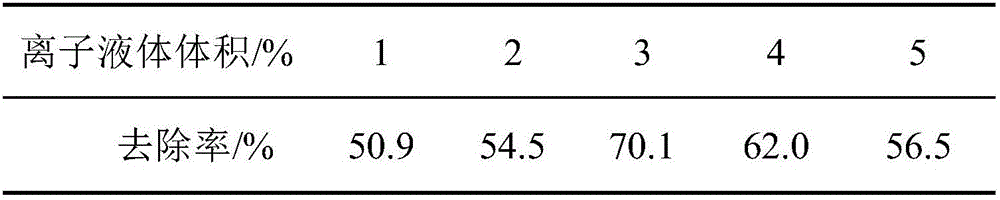

[0020] Sequentially weigh 0.500g soil samples into a series of 15mL centrifuge tubes, add 0.2mol / L oxalic acid respectively, and then add 1%, 2%, 3%, 4%, 5% of the total liquid volume of choline chloride / urea ionic liquid. Shake at constant temperature for 4 hours, centrifuge at 4000r / min for 20 minutes, take 1ml of the supernatant in a 25ml colorimetric tube, and use 1.5% HNO 3 Prepare the test at constant volume, and each group has 3 parallels. The removal effects of different volumes of choline chloride / urea ionic liquid on lead in soil are shown in Table 1.

[0021] Table 1

[0022]

Embodiment 2

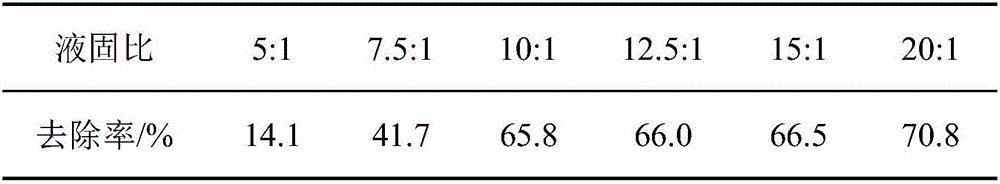

[0024] Sequentially weigh 0.500g soil samples into a series of 15mL centrifuge tubes, add 3% choline chloride / urea ionic liquid, and then add oxalic acid with a concentration of 0.2mol / L respectively, and fix the liquid-solid ratio at 5:1, 7.5: 1. 10:1, 12.5:1, 15:1, 20:1, shake at constant temperature for 4 hours, centrifuge at 3500r / min for 15 minutes, take 1ml of the supernatant in a 25ml colorimetric tube, and use 1.5% HNO 3 Prepare the test at a constant volume, and each group has 3 parallels. The removal effects of different liquid-solid ratios on the lead in the soil are shown in Table 2.

[0025] Table 2

[0026]

Embodiment 3

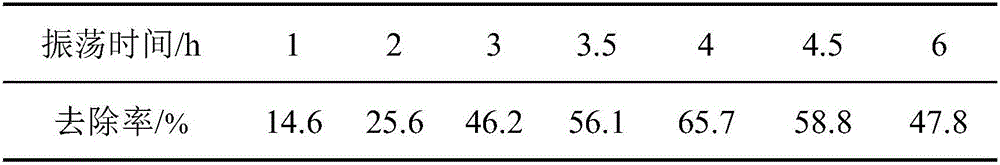

[0028] Sequentially weigh 0.500g soil samples into a series of 15mL centrifuge tubes, add 3% choline chloride / urea ionic liquid, and then add 9.7mL oxalic acid with a concentration of 0.2mol / L, and fix the liquid-solid ratio at 20:1 , shake at constant temperature for 1h, 2h, 3h, 3.5h, 4h, 4.5h, 6h, centrifuge at 4000r / min for 20min, take 1ml of the supernatant in a 25ml colorimetric tube, and use 1.5% HNO 3 Prepare the test at a constant volume, and each group has 3 parallel samples. The removal effects of different oscillation times on lead in the soil are shown in Table 3.

[0029] table 3

[0030]

[0031] control group

[0032] Weigh 0.500g of soil samples in sequence into a series of 15mL centrifuge tubes, and add 10mL of oxalic acid with concentrations of 0.01, 0.03, 0.05, 0.10, 0.15, 0.20, and 0.40mol / L, respectively. Shake at constant temperature for 4 hours, centrifuge at 4000r / min for 20 minutes, take 1ml of the supernatant in a 25ml colorimetric tube, and use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com