Sleeved pipe resistance welding vacuum packaging method

A technology of vacuum packaging and resistance welding, applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inability to detect leakage of casing and casing, easy occurrence of holes in quartz tubes, and inability to hot isostatic pressing. Achieve high sealing and welding efficiency and success rate, good plastic toughness, and good vacuum effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

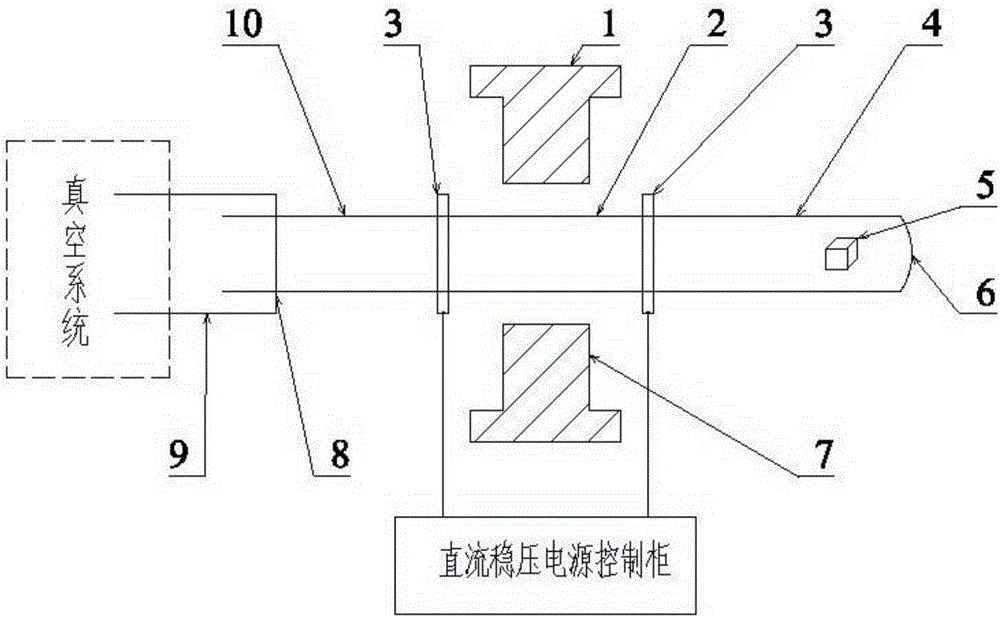

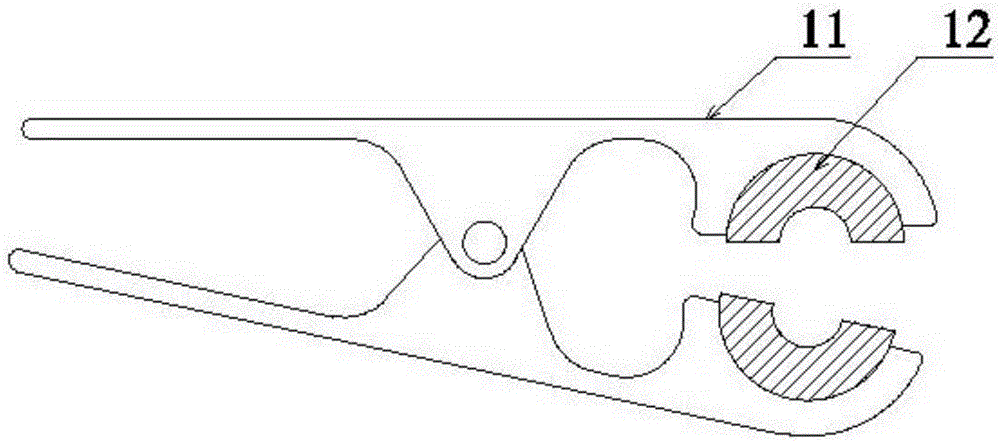

[0021] The sheathing tube vacuum packaging process of the present invention is mainly based on the concept of physical vacuum isolation, using the metal sheathing tube as a sample container or as a carrier for vacuuming and resistance welding. After evacuating the metal sheathed tube containing the sample to the expected vacuum degree, place the sheathed tube between the two electrodes and pass an electric current. The area where the current passes will generate resistance heat. When the area is heated to a certain temperature, Apply a certain pressure on the heating area with hydraulic flat-nose pliers and keep it for a certain time, so that the heating area forms a closed welded joint, so that the sample is sealed in the metal clad tube. Then the packaged samples are placed in a conventional heat treatment furnace for heat treatment experiments or placed in hot isostatic pressing equipment to prepare materials.

[0022] The present invention relates to the experimental devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com