Cleaning fusion method and fusing furnace for glass metal

A glass melting furnace and glass liquid technology, applied in glass melting devices, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of limited melting temperature and melting amount, difficult to melt high-melting glass raw materials on a large scale, etc. The area is reduced, the emission reduction effect is remarkable, and the effect of reducing the investment of the kiln

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

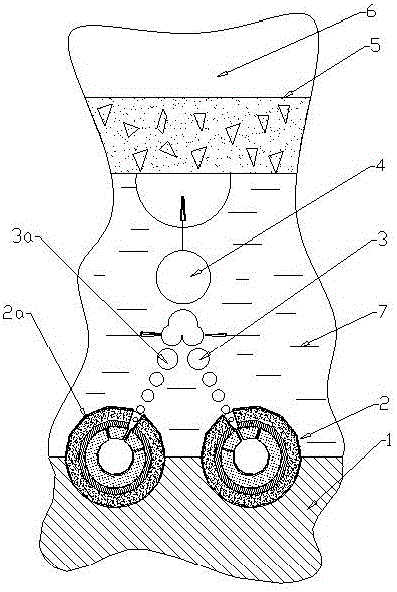

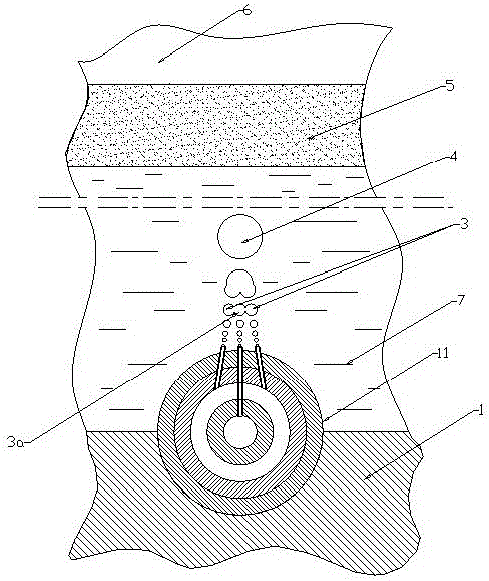

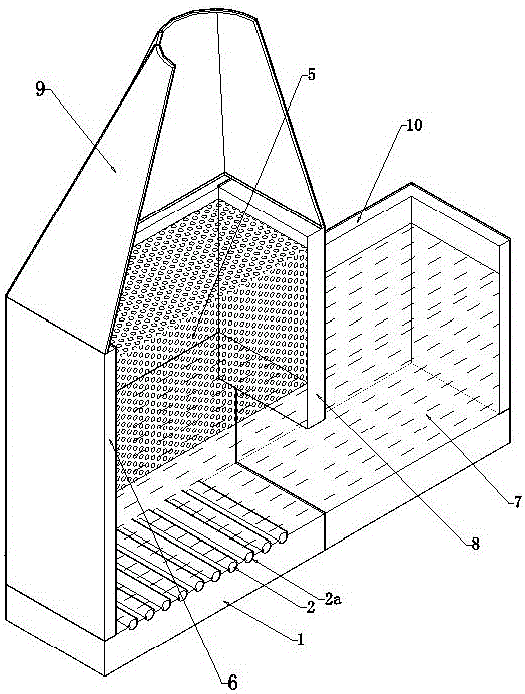

[0017] figure 1 In the process, the nozzle composed of oxygen injector 2 and hydrogen injector 2a is immersed in the burner, arranged at the bottom of the melting pool of the glass melting furnace, and sprays or blows oxygen bubbles 3 and hydrogen bubbles into the molten glass 7 respectively 3a, they meet and burn during the ascent in the molten glass 7, forming combustion bubbles 4; thereby transferring heat to the molten glass 7 and the high accumulation layer 5 of glass batch covering the glass liquid surface , to achieve the purpose of melting the glass batch and clarifying and homogenizing the glass liquid.

[0018] Wherein the height of the high stockpiling layer 7 of the glass batch material is more than 0.5 meters, up to several meters to more than ten meters. The glass batch material in the high-stock layer 5 of the above-mentioned glass batch material is a granulated material that has been processed by processes such as balling or briquetting.

[0019] figure 2 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com