A method for preparing low-ester pectin by ammonium exchange method

A low-ester pectin and high-ester pectin technology, which is applied in the field of food processing, can solve the problems of high equipment requirements, high production costs, and high requirements for supporting auxiliary equipment, and achieve simple process flow, mild reaction conditions, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Add 3g of pectin powder to a 100ml Erlenmeyer flask, then add distilled water to 100ml, shake to completely dissolve the pectin.

[0026] 2) When the pectin is completely dissolved, add 7ml of 25g / L ammonium acetate solution, and stir at 40°C for 24h.

[0027] 3) Use hydrochloric acid to adjust the pH of the solution to 2, then add 2 times the volume of absolute ethanol, stir evenly, filter to obtain pectin precipitate, dry with hot air at 40°C to constant weight, and pulverize to obtain low-ester pectin.

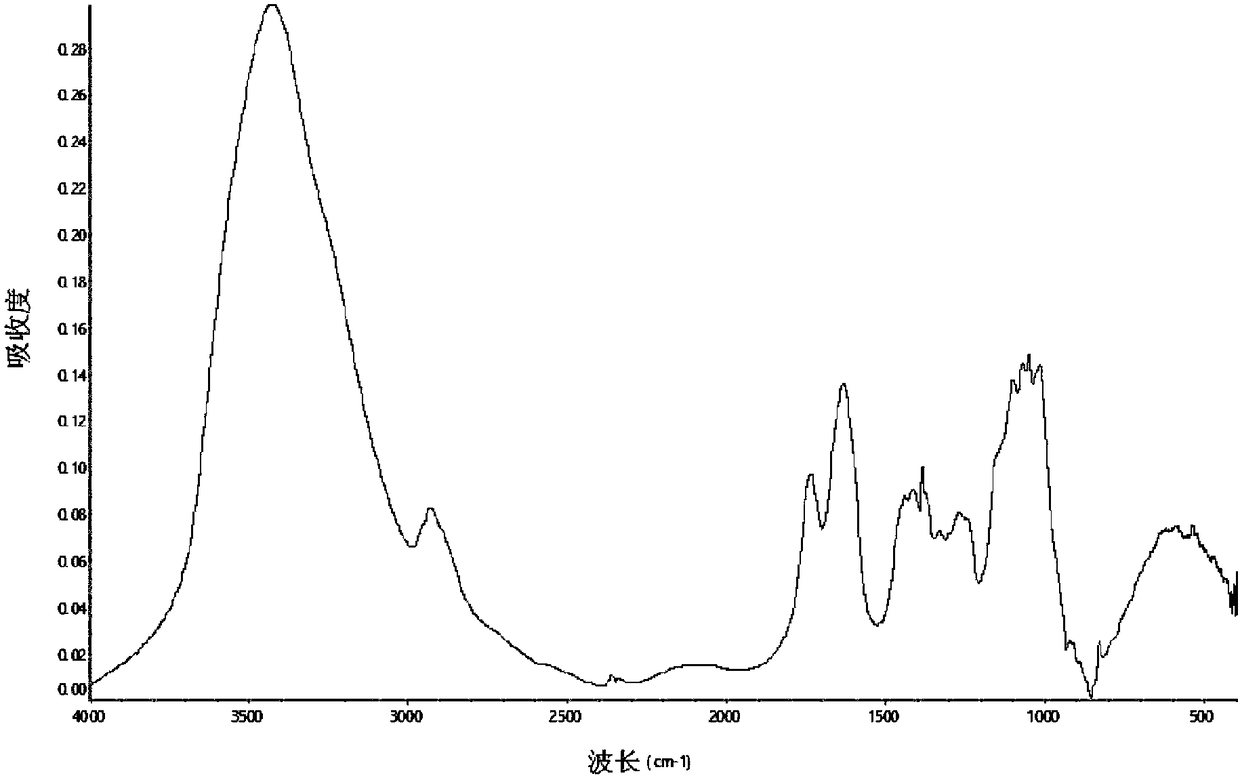

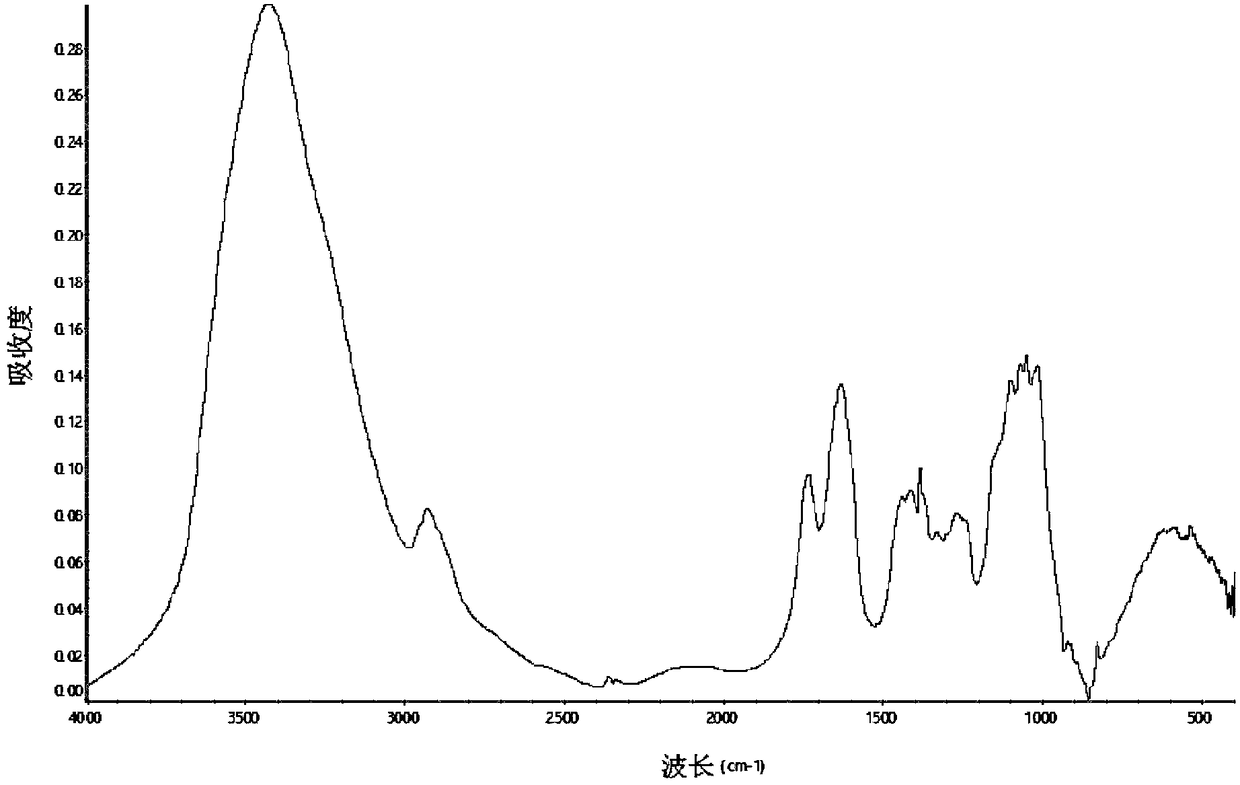

[0028] The degree of esterification of low-ester pectin was determined to be 43% by titration. After the sample was dried, the composition of the sample was analyzed by infrared spectroscopy and compared with a low-ester pectin standard, such as figure 1 and figure 2 . The results showed that the absorption peaks of the samples were basically consistent with those of the standard substance, indicating that this method only reduced the degree of esterification ...

Embodiment 2

[0030] 1) Add 2g of pectin powder into a 100ml Erlenmeyer flask, then add distilled water to 100ml, shake to completely dissolve the pectin.

[0031] 2) When the pectin is completely dissolved, add 4.5ml of 20g / L ammonium acetate solution, and stir at 70°C for 1h.

[0032] 3) Use hydrochloric acid to adjust the pH of the solution to 1, then add 3 times the volume of absolute ethanol, stir evenly, filter to obtain pectin precipitate, dry with hot air at 50°C to constant weight, and pulverize to obtain low-ester pectin.

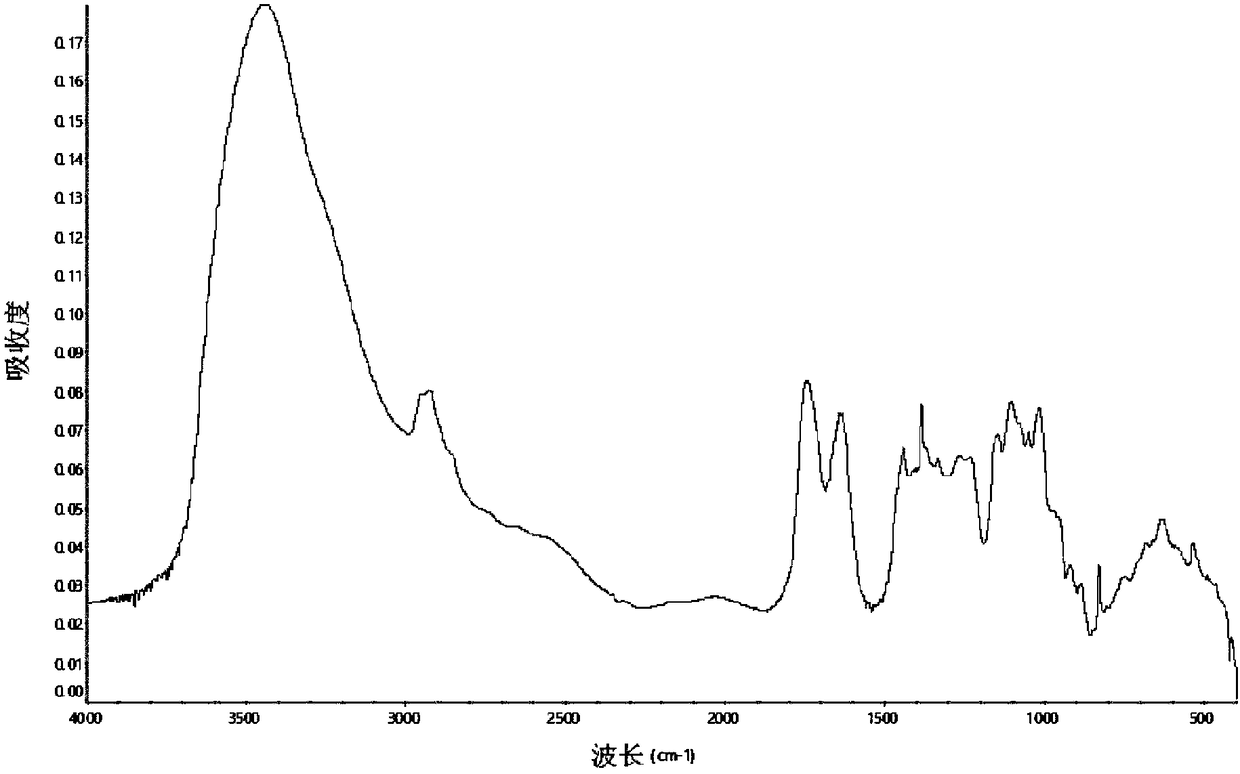

[0033] The esterification degree of gained low-ester pectin is 49%, and infrared spectrum sees image 3 .

Embodiment 3

[0035] 1) Add 4g of pectin powder to a 100ml Erlenmeyer flask, then add distilled water to 100ml, shake to completely dissolve the pectin.

[0036] 2) When the pectin is completely dissolved, add 6ml of 30g / L ammonium acetate solution, and stir at 50°C for 12h.

[0037] 3) Use hydrochloric acid to adjust the pH of the solution to 3, then add 5 times the volume of absolute ethanol, stir evenly, filter to obtain pectin precipitate, dry with hot air at 60°C to constant weight, and pulverize to obtain low-ester pectin.

[0038] The esterification degree of gained low-ester pectin is 45%, and infrared spectrum sees Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com