Scratch-resistant high-gloss spray-free pc/asa alloy material and preparation method thereof

An alloy material and spray-free technology, which is applied in the field of polymer molding and polymer blending, can solve the problems of fogging on the high-gloss surface, poor dispersion, poor compatibility between scratch-resistant agents and material substrates, etc., to achieve Improve compatibility, strengthen dispersion, and solve the effect of fogging problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

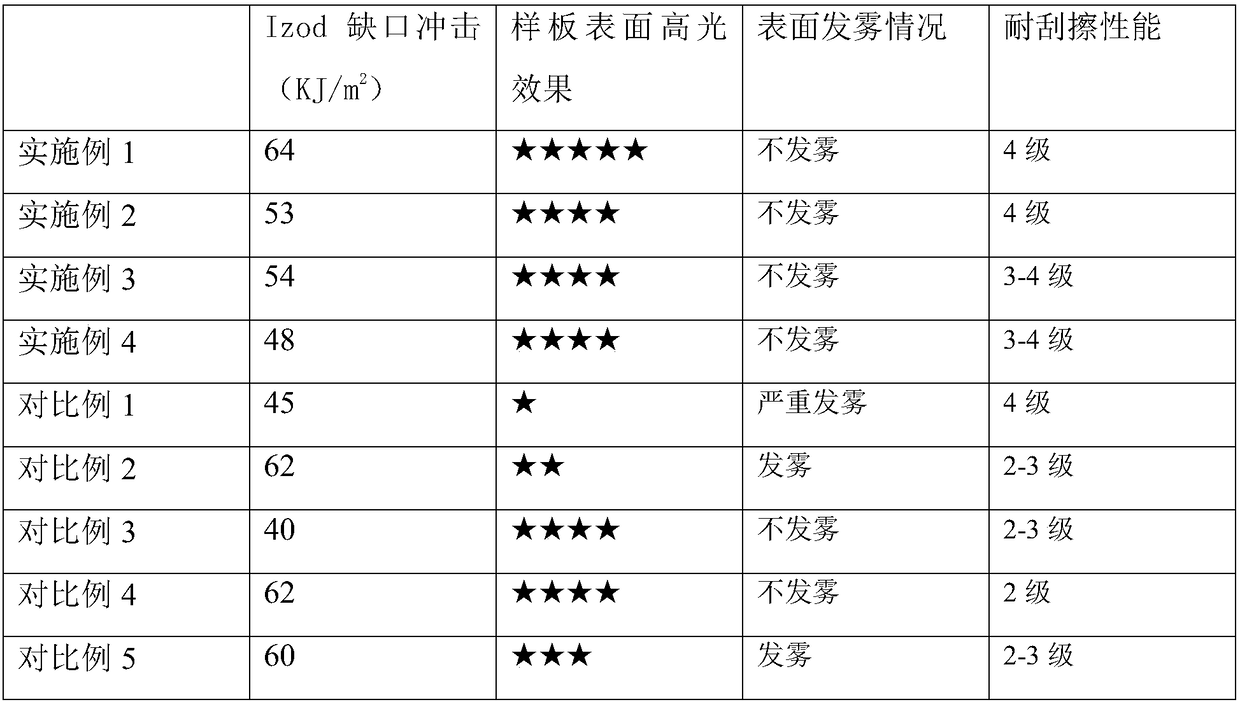

Examples

preparation example Construction

[0025] The preparation method of scratch-resistant high-gloss spray-free PC / ASA alloy material in the described embodiment and comparative example comprises the following steps:

[0026] S1. After mixing all the components through the mixer, feed them from the main feeding port of the twin-screw extruder;

[0027] S2. Melt extrusion and granulation to obtain scratch-resistant high-gloss PC / ASA alloy material without spraying;

[0028] A special die is added to the die of the twin-screw extruder. One end of the special die is provided with an inlet and the other end is provided with an outlet. The inlet is connected to the die of the twin-screw extruder; the diameter of the inlet is larger than the diameter of the outlet.

[0029] The barrel temperature of the twin-screw extruder is successively set to 200°C, 240°C, 260°C, 260°C, 260°C, 240°C, 240°C, 250°C, 260°C and 260°C; 500-800rpm.

[0030] The length of the special die is 120mm, the outlet size is 1mm×50mm, and the inlet...

Embodiment 1

[0042] A scratch-resistant high-gloss spray-free PC / ASA alloy material and a preparation method thereof, the method comprising the following steps:

[0043] (1) Weigh each component by weight: PC: 70, ASA: 10, scratch resistance agent: 18, compatibilizer: 5, carbon black masterbatch: 2; antioxidant 1010 0.1, antioxidant 168 0.1, lubricant 0.3,

[0044] (2) Feed all the raw materials from the main feeding port, melt and extrude at 200-260°C, the screw extruder rotates at 500rpm, melt and extrude, and granulate to obtain the product.

[0045] A special die is added to the die of the twin-screw extruder to make the flow channel generate a strong stretching flow, which is composed of a continuous flow channel whose diameter changes from large to small.

Embodiment 2

[0047] A scratch-resistant high-gloss spray-free PC / ASA alloy material and a preparation method thereof, the method comprising the following steps:

[0048](1) Weigh each component by weight: PC: 50, ASA: 25, anti-scratch agent: 20, carbon black masterbatch: 2; compatibilizer: 3; antioxidant 1010 0.1, antioxidant 168 0.1, lubricant 0.3

[0049] (2) Feed all the raw materials from the main feeding port, melt and extrude at 200-260°C, the screw extruder rotates at 500rpm, melt and extrude, and granulate to obtain the product.

[0050] A special die is added to the die of the twin-screw extruder to make the flow channel generate a strong stretching flow, which is composed of a continuous flow channel whose diameter changes from large to small.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com