50 steel ultrafine martensite isothermal quenching thermal treatment hardening process

A technology of austempering and ultra-refining, applied in the field of 50 steel ultra-refinement martensitic austempering heat treatment hardening process, can solve the problems of limited improvement of performance indicators and not very significant effect, and achieve the effect of improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

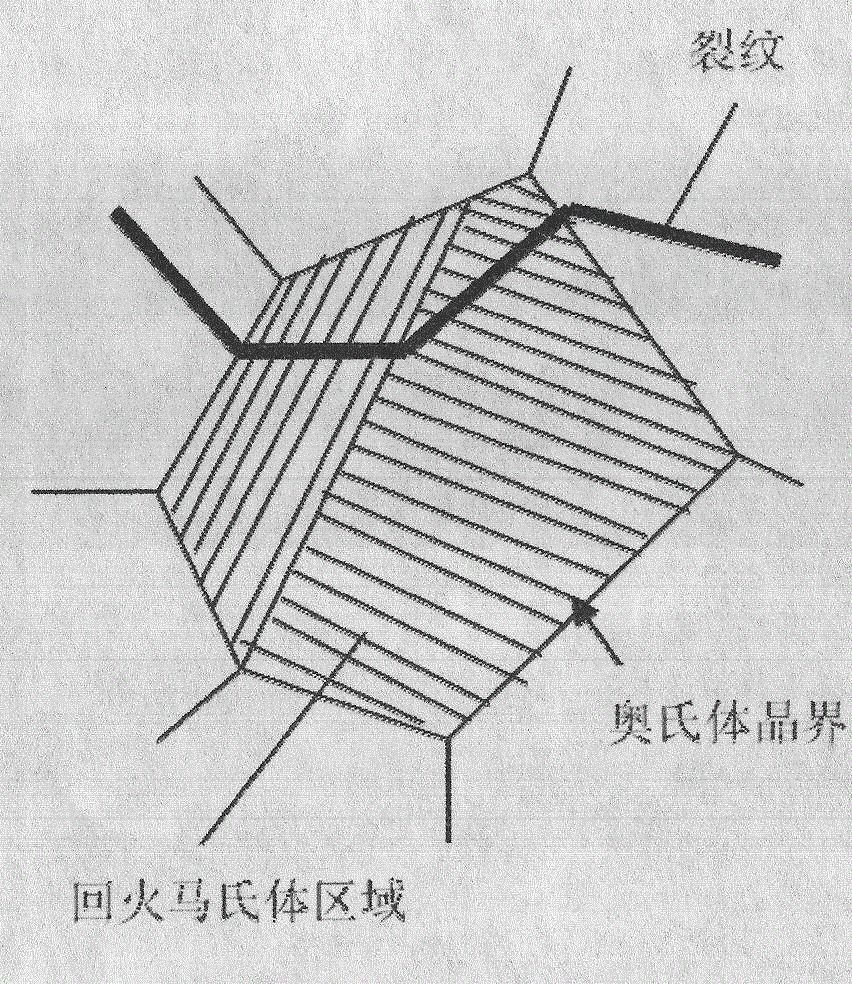

[0028] Figure 1A It is a diagram of the diffusion mechanism of micro-cracks in the austenite grains of 50 steel after ordinary and traditional heat treatment 50 steel is quenched and tempered;

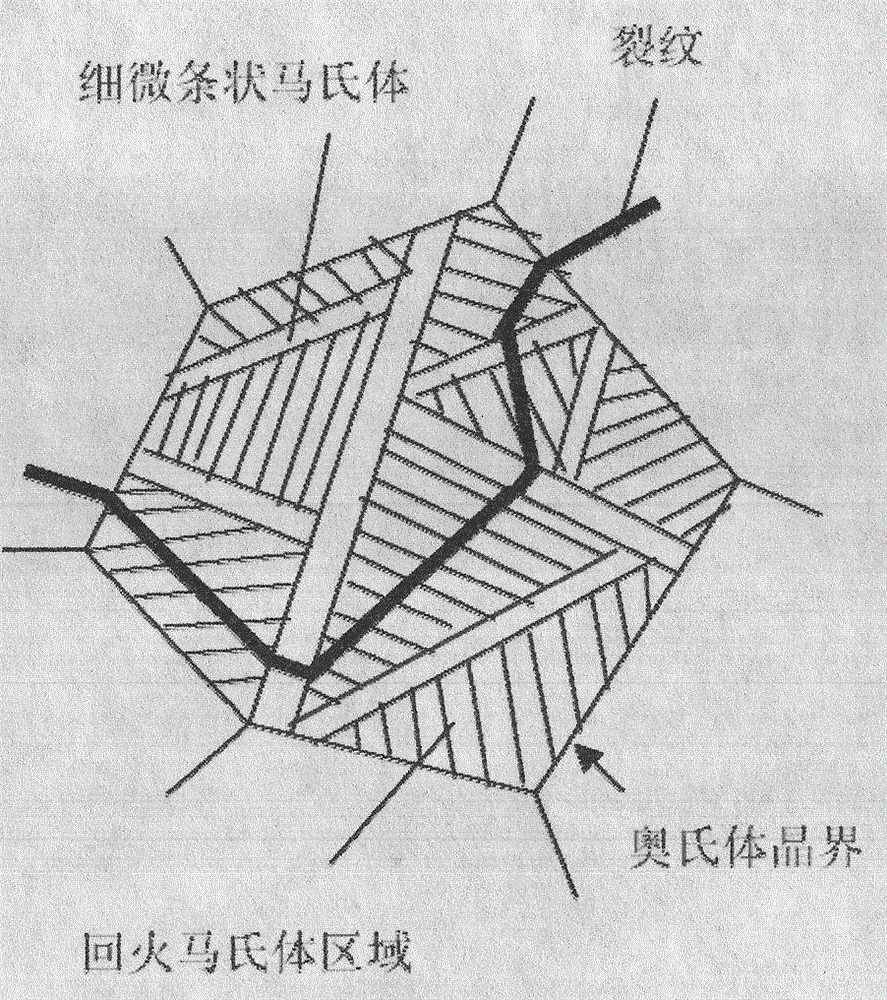

[0029] Figure 1B It is the micro-crack diffusion mechanism diagram of the austenite grain inside the 50 steel after the ultrafine martensitic isothermal heat treatment adopted in this patent;

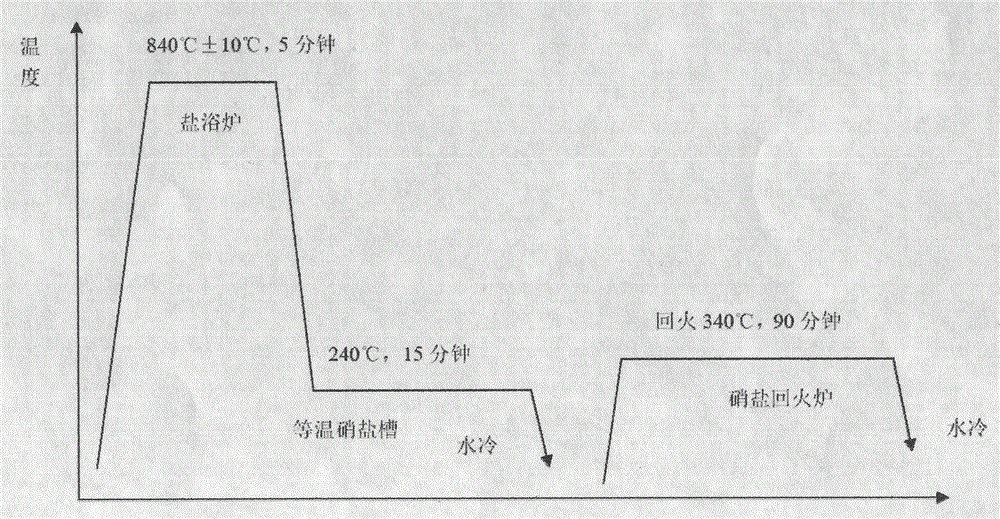

[0030] heat treatment image 3 The 50 steel spring piece shown as an example, material: 50 steel, technical requirements, heat treatment hardness is 44HRC-49HRC; surface treatment: dip black electrophoretic paint after phosphating; inspection: transverse tensile force ≥ 11KN.

[0031] Combination process figure 2 , After binding the stamped 50 steel spring pieces with iron wires, put them vertically into the salt bath furnace. The pieces are quenched into the isothermal nitrate tank, the temperature of the nitrate tank is controlled at 240 ° C, the 50 steel spring pieces are kept in the ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com