After-treatment processing method and equipment of flat electronic grade glass fiber cloth

A technology of glass fiber cloth and glass fiber, which is applied in the post-processing method and equipment field of flat electronic grade glass fiber cloth, and can solve the problem of small width of warp and weft yarns, poor uniformity of fiber opening, and fiber opening treatment of electronic grade glass fiber cloth. Unsatisfactory effect and other problems, to achieve the effect of thin thickness and low air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

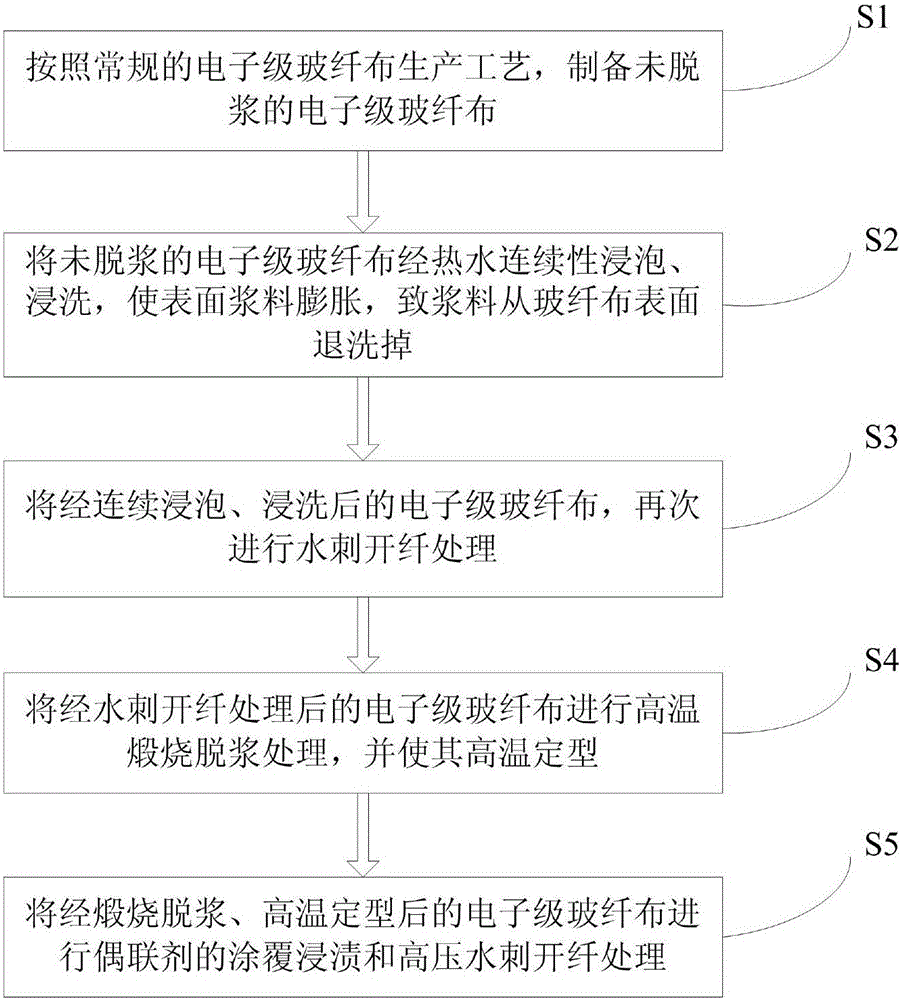

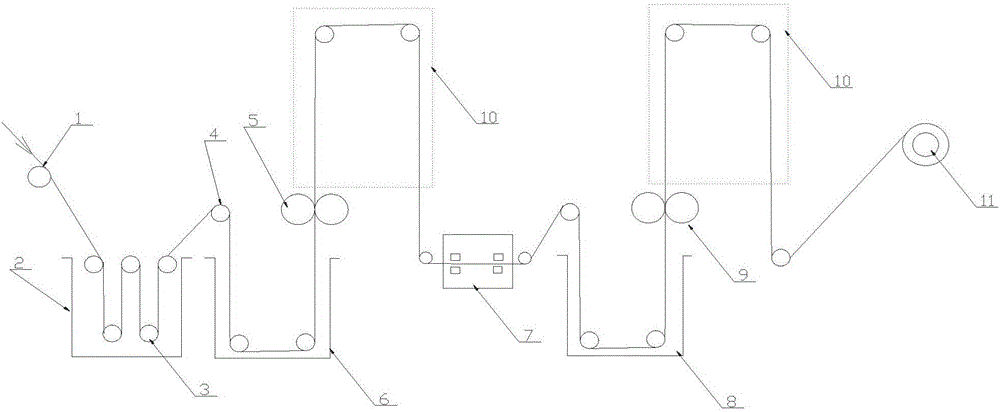

[0031] The present invention will be further elaborated below with reference to the accompanying drawings.

[0032] In this embodiment, the glass fiber yarn used in the glass fiber cloth itself is twisted from hundreds of monofilaments, and in order to ensure the weaving efficiency and weaving quality, the surface of the warp yarn is also coated with a layer of size film before weaving to improve its weaving. Bundle. However, the woven glass fiber yarn remains in a bundled state, which is greatly hindered by the flatness, air permeability, and impregnation of the glass cloth. Therefore, the slurry on the surface of the glass fiber cloth needs to be removed. In addition, in order to improve the performance of the glass fiber cloth, the glass fiber cloth needs to be fiber-opened. The thinner the glass fiber cloth, the finer the fiber diameter of the glass fiber yarn used, and the more difficult the flat fiber opening technology is. Blindly increasing the fiber opening strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com