Dyeing method for nylon-56 fibers

A dyeing method and technology of nylon, which is applied in dyeing, textiles and papermaking, and can solve the problems of fiber strength decline, acid and alkali resistance difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, nylon 56 fiber dyeing

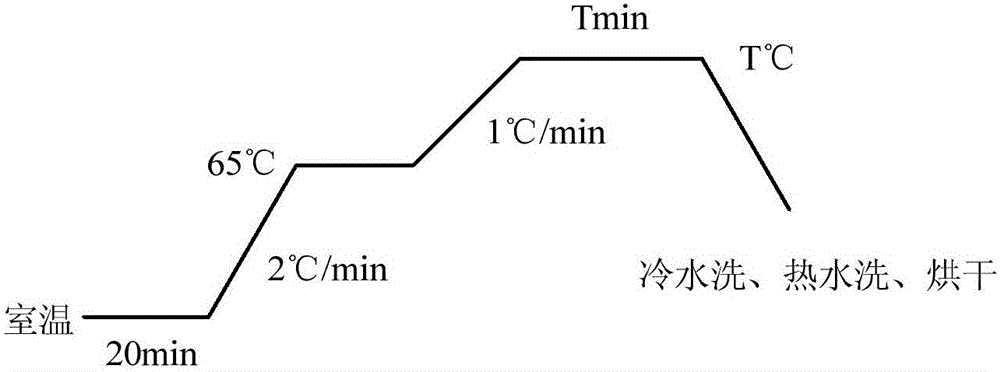

[0033] According to the bath ratio of 1:50 (mass ratio of nylon 56 fiber to dye liquor), dye (2% owf), leveling agent O-15 (1g / L) and acid release agent (1g / L) were prepared into dye liquor, according to figure 1 In the middle dyeing process curve, the dyeing experiments were carried out at 50°C, 60°C, 65°C, 70°C, 80°C and 90°C respectively for half an hour.

[0034] The dye used is weak acid brilliant red B (C.I.Acid Red 249), and the test results after dyeing are shown in Table 2:

[0035] Table 2 Color fastness index of dyed nylon 56 fiber

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com