A Novel AGC Control Method for Circulating Fluidized Bed Boiler

A technology of circulating fluidized bed and control method, which is applied in the directions of fluidized bed combustion equipment, combustion method, and fuel burned in a melted state, etc., can solve the problem of accelerated equipment loss, frequent fluctuation of control system performance in production process, and non-stationary random signal disturbance. and other problems to achieve the effect of reducing lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The technical solution of the present invention will be further introduced below in combination with specific embodiments.

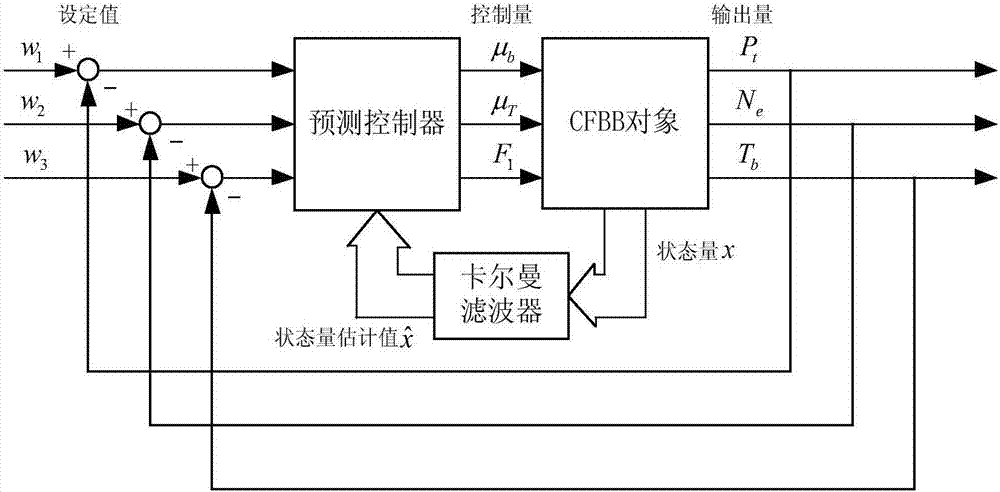

[0085] The CFB boiler control object model involved in this example is obtained by system identification based on relevant test data of a certain power plant. In order to illustrate the advantages of the new AGC control structure, in this example, two sets of different control object transfer function models are obtained by identifying the data related to the 75% load condition, which are the 2×2 transfer function model based on the traditional 2×2 AGC control structure and the The 3×3 transfer function model based on the new 3×3 AGC control structure; the predictive control algorithm based on the state space model obtains the corresponding dynamic parameter matrix through the step response test of the object.

[0086]

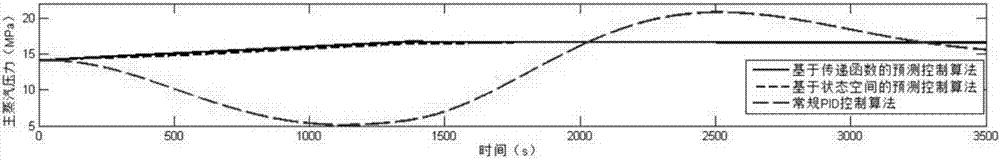

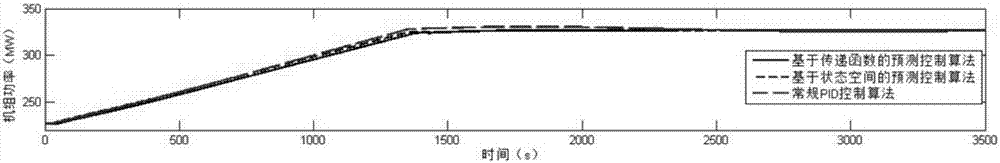

[0087] Below, this example is based on two different transfer function models for simulation verification. For the transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com