Steel blade residual stress micro-magnetic nondestructive testing method and steel blade residual stress micro-magnetic nondestructive testing device based on incremental permeability

A technology of incremental magnetic permeability and residual stress, which is applied in the direction of measuring device, measurement of change force of material magnetic properties caused by applied stress, measurement of force, etc., can solve the problem of expensive measuring instruments, cumbersome operation, measurement complex methods, etc.

Active Publication Date: 2016-08-24

BEIJING UNIV OF TECH

View PDF5 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

And the measurement method is complicated, the operation is cumbersome, and the price of the measuring instrument is relatively expensive

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0034] For small T-shaped blades 4, use the micromagnetic non-destructive testing device ( figure 1 ) for detection. The pincer clamp 3 at the end of the manipulator 1 clamps the T-shaped blade 4 blade root. The manipulator 1 is fixed on the manipulator motion controller 2 . The micro-magnetic probe 5 is fixed on the workbench base 6 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

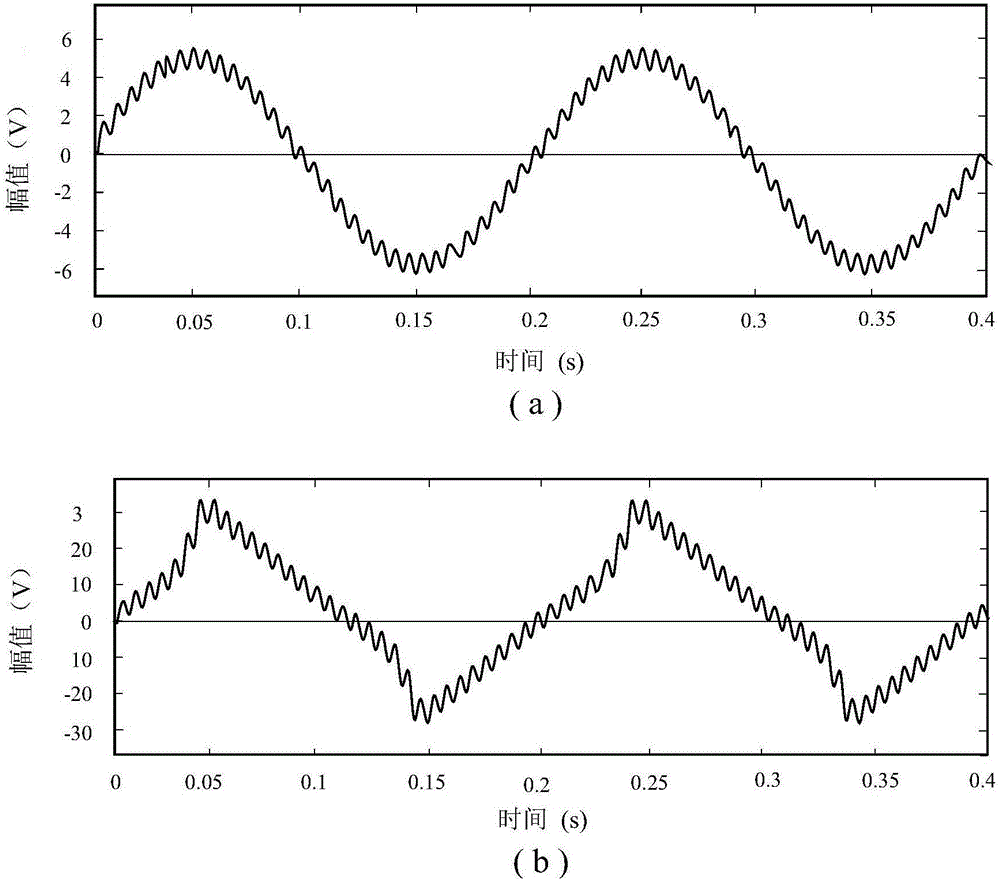

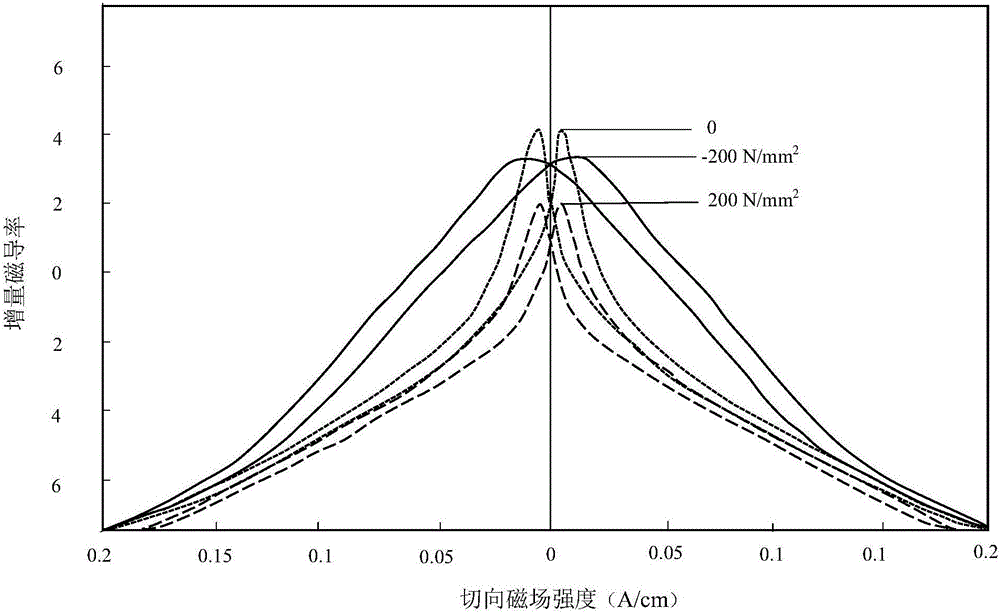

A steel blade residual stress micro-magnetic nondestructive testing method and a steel blade residual stress micro-magnetic nondestructive testing device based on incremental permeability belong to the technical field of steel blade residual stress nondestructive testing. An automatic manipulator clamps a micro-magnetic probe to scan a steel blade to detect micro-magnetic signals, then, incremental permeability is extracted to represent residual stress, and finally, the residual stress distribution of the whole blade is acquired. The testing device mainly comprises a manipulator, a micro-magnetic probe, a system control and micro-magnetic signal collecting and processing module, and the like. The testing device can work in two modes: a blade motion testing mode and a probe motion scanning mode. In the blade motion testing mode, the micro-magnetic probe is fixedly mounted on the base of a workbench, a pincer-like clamp is mounted at the end of the manipulator, a blade is clamped to move along a preset curved surface relative to the micro-magnetic probe, and thus double sides of the blade are tested. In the probe motion scanning mode, a steel blade is fixedly mounted on an open ring clamp, the end of the manipulator clamps the micro-magnetic probe to scan the surface of the steel blade, and the blade can be turned to complete double-side testing by rotating a driving mechanism.

Description

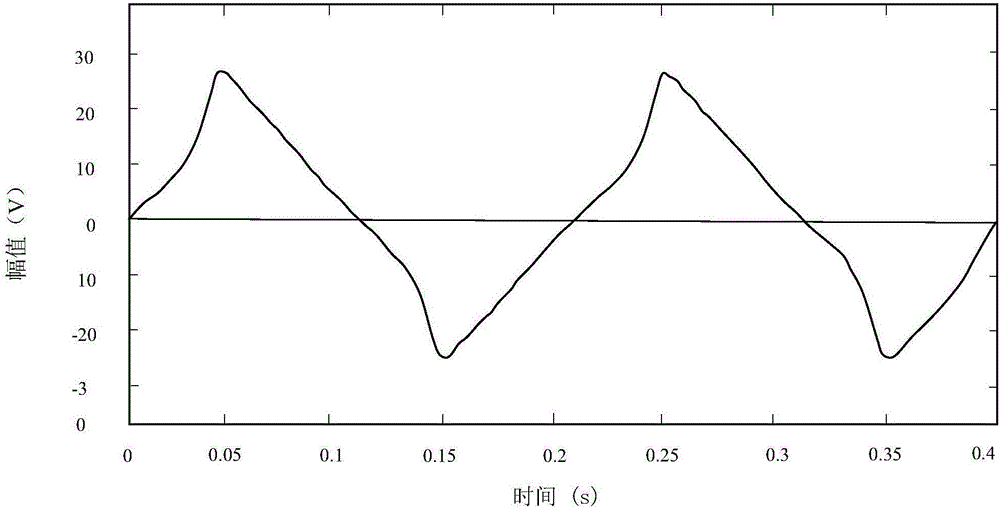

Technical field: [0001] The invention relates to a technology for non-destructive detection of residual stress on the surface of steel blades, in particular to a method and device for micro-magnetic non-destructive detection of residual stress of steel blades based on incremental magnetic permeability. Background technique: [0002] In industrial applications of steam turbines, the working environment of the final blades is extremely harsh. Water erosion, stress corrosion, and fatigue often cause damage and failure of blades. Blade breakage often leads to serious safety accidents for the entire unit. Two technological measures are often used to improve the water erosion resistance of the blade. The first is to perform local high-frequency quenching and strengthening on the steam inlet side of the blade. After local high-frequency quenching, although the anti-corrosion ability of the blade is improved, high-frequency quenching will change the tissue stress. The residual st...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01L1/12G01N27/72

CPCG01L1/127G01N27/72

Inventor 何存富冉德强刘秀成吴斌

Owner BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com