Method for detecting concentrations of sulfuric acid and phosphoric acid in chemical polishing liquid containing sulfuric acid and phosphoric acid

A technology of phosphoric acid chemistry and phosphoric acid concentration, applied in the detection of sulfuric acid, phosphoric acid concentration, and sulfuric acid in phosphoric acid chemical polishing liquid, can solve problems such as inability to achieve results, and achieve the effect of reducing replacement cycle and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Embodiment: the present invention detects the method for sulfuric acid, phosphoric acid concentration in sulfuric acid, phosphoric acid chemical polishing liquid, specifically comprises the steps:

[0018] (1), get 5ml chemical polishing bath solution in the volumetric flask of 100ml to constant volume;

[0019] (2), get 20ml constant volume solution, be divided into two parts of equal volume, each part is 10mL, utilize potentiometric automatic titrator, the solution is detected;

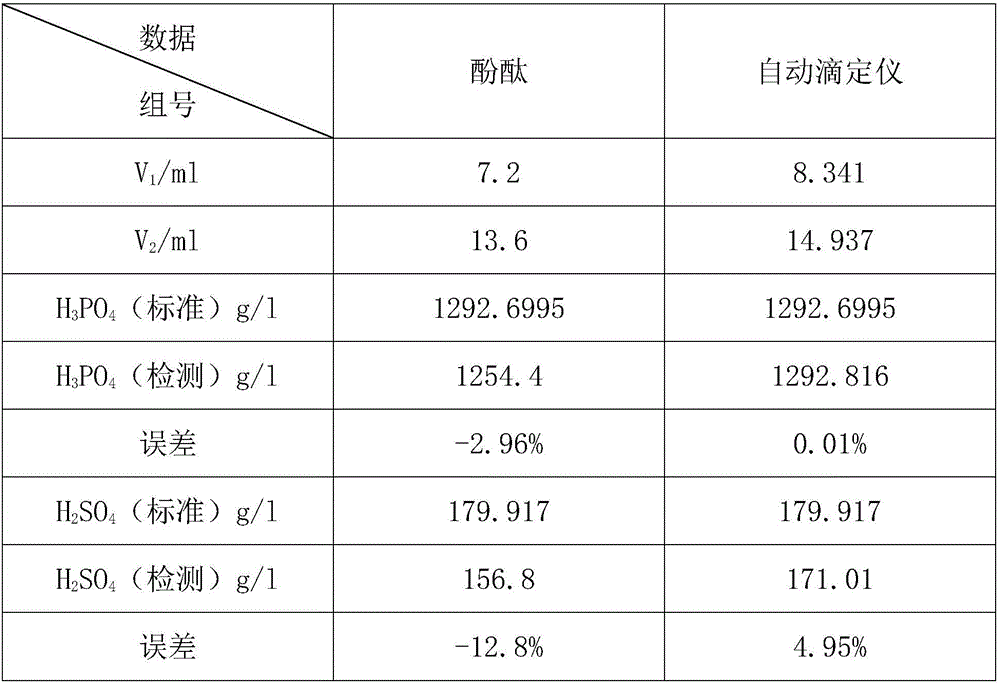

[0020] (3), the volume of the sodium hydroxide consumed when recording the first stoichiometric point (PH=4.7) is V1; The volume of the sodium hydroxide consumed when recording the first stoichiometric point (PH=9.7) is V2, According to the calculation formula m H3PO4 =(V 2 -V 1 )*C NaOH *98*b,C H3PO4 = m H3PO4 / V;C H2SO4 =(2V 1 —V 2 )*98*C NaOH Obtain the concentration of sulfuric acid and phosphoric acid.

[0021] (4), configure sulfuric acid, phosphoric acid 1:9 chemical throwin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com